+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

When it comes to heavy machinery, the functionality and reliability of components are crucial for optimal performance. One key element that can significantly affect the longevity and efficiency of hydraulic systems is the Cylinder Seal Kit. As John Miller, a renowned expert in heavy equipment maintenance, once stated, "Cylinder Seal Kits are the unsung heroes of machinery performance; without them, even the most powerful machines would falter." This statement underscores the importance of understanding and selecting the right seal kits to ensure that your equipment operates at peak efficiency.

In this ultimate guide, we will delve into the essentials of Cylinder Seal Kits, exploring their various types, benefits, and the critical role they play in minimizing downtime and costly repairs. Whether you're managing an expansive fleet of heavy equipment or overseeing a single machine, having a comprehensive knowledge of these kits can save you time and money in the long run. Join us as we break down everything you need to know to make informed decisions about your Cylinder Seal Kits, ensuring your heavy equipment runs smoothly and efficiently.

Cylinder seal kits are essential components in heavy machinery, ensuring the proper functioning of hydraulic and pneumatic systems. Essentially, a cylinder seal kit includes various seals, O-rings, and gaskets that prevent fluid leaks and maintain pressure within the cylinders. These kits come in various types, tailored to different equipment and operational requirements, including rod seals, piston seals, and backup rings. Understanding these types is crucial for selecting the right kit for your heavy equipment needs.

Tip: When choosing a cylinder seal kit, always verify compatibility with your specific machinery model to avoid installation issues.

Regular maintenance of seal kits is also vital to prolong their lifespan and ensure smooth operation. Signs of wear, such as hydraulic leaks or decreased system performance, indicate that it might be time to replace your seals.

Tip: Keep an eye on the operating conditions, like temperature and pressure, as they greatly affect seal durability. Regular inspections can help catch potential issues early, saving on costly downtime or repairs.

When it comes to maintaining heavy equipment, understanding the key components of cylinder seal kits is crucial for optimal performance and longevity. These kits are designed to ensure airtight and fluid-tight seals within hydraulic cylinders, facilitating the efficient operation of heavy machinery. Key components typically include O-rings, backup rings, and various types of seals tailored to withstand the high pressures and demanding environments these machines operate in.

Choosing the right cylinder seal kit can significantly reduce downtime and repair costs. It is essential for equipment owners and repair facilities to be familiar with the specific types of seals that are compatible with their machinery. Common issues that may arise from worn or improperly installed seals can lead to hydraulic fluid leaks and decreased performance, underscoring the importance of selecting high-quality replacement parts. Regularly inspecting cylinder seals and knowing when to replace them can make a difference in the overall operational efficiency of heavy-duty machinery.

| Component Name | Material | Application | Temperature Resistance | Pressure Rating |

|---|---|---|---|---|

| O-Ring Seal | Nitrile Rubber | Hydraulic Cylinders | -30°C to 100°C | 3500 psi |

| Rod Seal | Polyurethane | Heavy Equipment | -20°C to 90°C | 4000 psi |

| Back-Up Ring | PTFE | Static Applications | -40°C to 260°C | 5000 psi |

| Piston Seal | Nitrile | Cylinders & Valves | -25°C to 120°C | 4500 psi |

When it comes to heavy equipment operations, utilizing quality cylinder seal kits plays a vital role in ensuring optimal performance and longevity. These seal kits are designed to prevent hydraulic fluid leaks and maintain pressure within the system. By doing so, they not only enhance the efficiency of machinery but also reduce the risk of downtimes due to unexpected failures. The reliability provided by top-grade seal kits translates to increased productivity and lower operational costs in the long run.

Moreover, quality cylinder seal kits contribute to safer working conditions. Leaks can create hazardous environments, increasing the likelihood of accidents and injuries. By implementing high-quality seals, operators can minimize these risks significantly. Additionally, quality kits often come with warranties and assurances from reputable manufacturers, which offers peace of mind to users by ensuring they are backed by dependable support and resources. This combination of efficiency, cost-effectiveness, and safety makes investing in quality cylinder seal kits a wise choice for any heavy equipment operation.

This chart highlights the key benefits of using quality cylinder seal kits in heavy equipment operations. The scores reflect how each benefit contributes to overall effectiveness and reliability in operations.

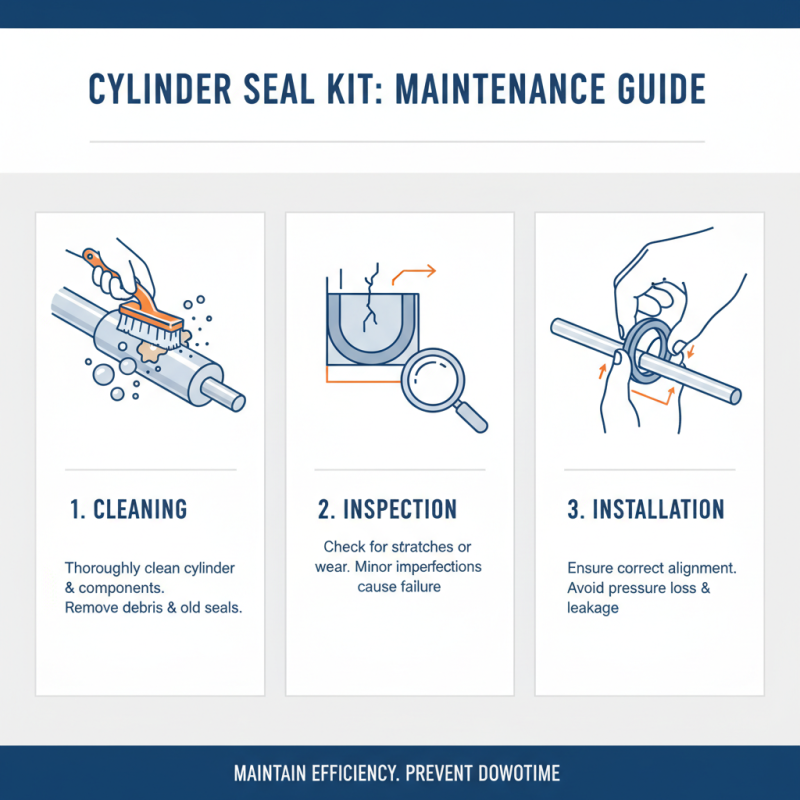

When it comes to maintaining the efficiency of heavy equipment, proper installation and regular maintenance of cylinder seal kits are crucial. The installation process begins with thorough cleaning of the cylinder and surrounding components. This step is essential to eliminate any debris or old seal remnants that could compromise the integrity of the new seals. Additionally, always inspect the cylinder for scratches or wear; minor imperfections can lead to seal failure. Ensure that the seals are aligned correctly during installation to avoid any pressure loss or leakage, which can significantly impact the equipment’s performance.

Once the cylinder seal kits are installed, maintenance plays an important role in prolonging their lifespan. Regularly check for signs of wear or leakage, as early detection can prevent more severe damage to the hydraulic system. It’s advisable to monitor the hydraulic fluid levels and quality, replacing the fluid as needed to minimize contaminants that could affect the seals. Implementing a scheduled maintenance plan that includes inspections and replacements of the seals at appropriate intervals will keep your heavy equipment running smoothly and efficiently for years to come.

Cylinder seal kits are crucial components in the operation of heavy equipment, often acting as the first line of defense against hydraulic fluid leaks and mechanical failures. Common issues that arise with these kits include wear and tear, improper installation, and material degradation. According to the Machinery Lubrication Magazine, up to 70% of hydraulic system failures can be traced back to seal failures, highlighting the importance of routine maintenance and proper troubleshooting techniques.

When servicing cylinder seal kits, it’s essential to identify the signs of trouble early. Symptoms such as excessive fluid loss, erratic cylinder movement, and visible leaks around the seals indicate that the kits may need inspection or replacement. The International Fluid Power Society reports that timely troubleshooting can reduce equipment downtime by up to 20%, emphasizing that operators should regularly check for issues like dirt contamination and misalignment, which can exacerbate seal damage. Following best practices in installation and maintenance can significantly enhance the lifespan of cylinder seal kits and ensure the reliable operation of heavy machinery.