+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

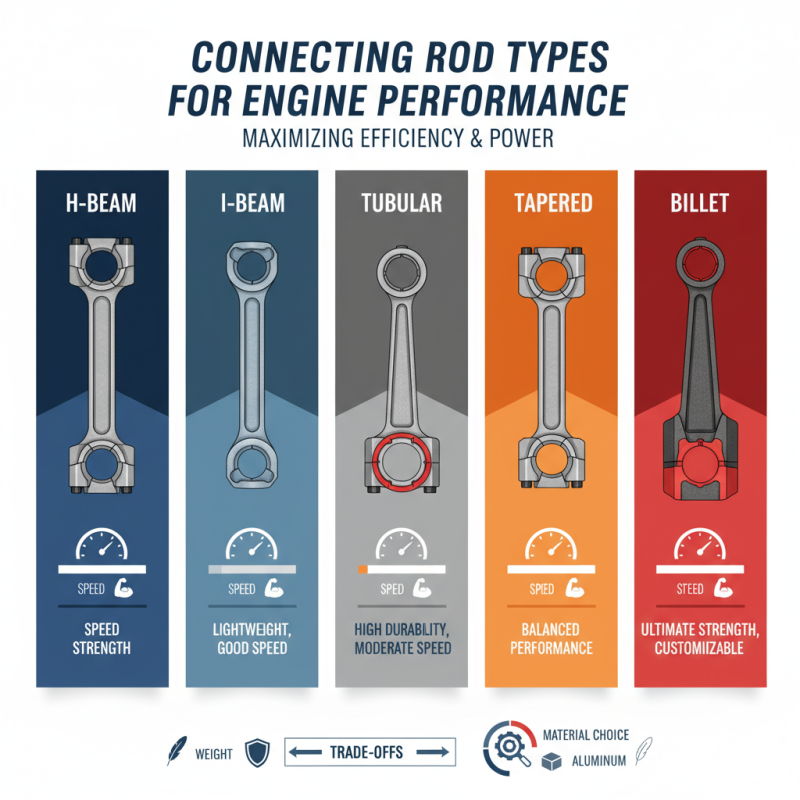

In the world of high-performance engines, the role of the connecting rod is crucial. Experts like John Smith, a renowned automotive engineer, emphasize, “The right connecting rod can make or break your engine’s performance.” Understanding the various types of connecting rods helps engineers maximize efficiency and power.

Connecting rods come in different designs, each offering unique advantages. A lightweight option can improve speed, while a robust one enhances durability. It's fascinating to see how material choices, such as steel or aluminum, directly impact performance. However, choosing the ideal connecting rod is not always straightforward.

Engineers often face trade-offs between weight and strength. A lightweight rod might not withstand extreme conditions, leading to potential failures. On the other hand, a heavier rod could hinder acceleration. This constant balancing act can be daunting. Nonetheless, comprehending these connecting rod types and their implications is essential for optimal engine function.

Connecting rods play a crucial role in the performance of an engine. They connect the piston to the crankshaft. Different types offer unique benefits. Each type can significantly affect how power is delivered. Some are built for strength, while others focus on weight. The balance between these factors is essential for an engine's efficiency.

Steel connecting rods are popular due to their durability. They can handle high horsepower situations. However, they are heavier, which can reduce overall performance. Aluminum rods, on the other hand, are lighter. This weight reduction helps engines rev faster, but they may not be as strong.

Titanium rods are an excellent compromise. They offer a unique blend of lightweight and strength. Many high-performance engines use them. However, their cost can be prohibitive for some builders. Each engine type has unique demands. Understanding the right rod can enhance performance. But there’s always the risk of overestimating capabilities. Choosing the wrong type can lead to failure and inefficiency. Proper research is essential to avoid costly mistakes.

Connecting rods play a vital role in an engine's performance. The material used in their construction significantly influences durability, weight, and cost. Common materials include aluminum, steel, and titanium.

Aluminum connecting rods are lightweight and offer good performance. They reduce the overall weight of the engine, potentially enhancing efficiency. However, their lower strength limits their use in high-performance applications. Research indicates that aluminum rods can handle around 20% less power than steel rods. This drawback makes them less suitable for extreme conditions.

Steel is often favored for its strength and affordability. It handles higher stress levels and provides better reliability. Studies show that steel rods can withstand forces of up to 35% more than comparable aluminum models. Yet, they are heavier, which can affect the engine's weight distribution.

Titanium rods are the ultimate choice for high-performance applications. They combine lightweight properties with incredible strength. However, the costs associated with titanium can be prohibitive. Reports say titanium rods can be 50% lighter than steel but come at a price premium that some engine builders find hard to justify.

When it comes to connecting rods, the choice between

I-Beam and H-Beam designs

is critical for engine performance. I-Beam rods are traditionally lighter and often allow for

faster engine response. They provide an efficient design that helps allocate stress effectively. Data shows that

I-Beam rods can improve performance metrics by up to 5% in certain

applications. This efficiency often leads to enhanced acceleration and better fuel economy.

On the other hand, H-Beam rods offer increased strength, making them ideal for high-performance engines.

H-Beam designs excel under extreme conditions and can handle higher power outputs. They typically have a wider

profile, which contributes to their durability. However, they are usually heavier than I-Beam rods,

potentially impacting responsiveness. Some experts argue that this extra weight could slightly hinder performance

in certain scenarios. Balancing strength and weight is key, and not all applications benefit from an

H-Beam's robustness. It’s essential to analyze the specific needs of your engine before making a choice.

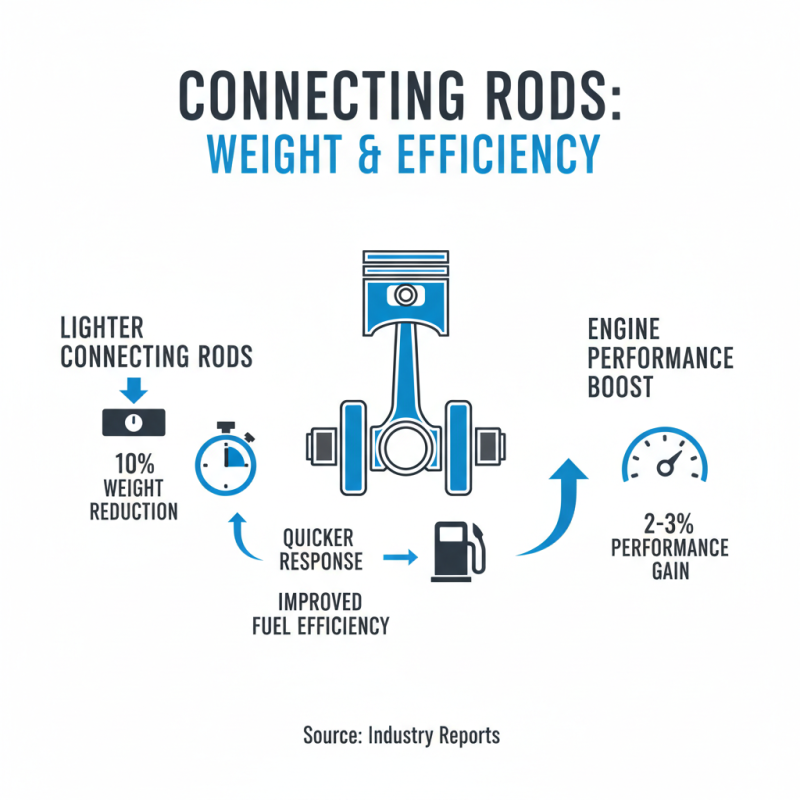

When considering connecting rod types, weight plays a crucial role in engine efficiency. A lighter connecting rod reduces the overall mass of the engine assembly. This leads to quicker engine responses and improved fuel efficiency. Industry reports suggest that a weight reduction of just 10% can enhance performance by 2-3%.

However, lighter materials may lack the necessary strength for high-performance applications. Thus, engineers face a balancing act between weight and durability. The choice of materials, such as aluminum versus steel, can make a noticeable difference. Aluminum offers significant weight advantages but can compromise strength under high stress.

The ideal connecting rod must optimize both mass and strength. Some manufacturers experiment with composite materials to reduce weight while maintaining integrity. A recent study showed that using advanced composites can cut weight by 30% while retaining performance. Yet, this innovation requires further development and testing to confirm reliability in real-world conditions. Balancing these factors is essential for achieving optimal performance.

When choosing a connecting rod, understanding your engine type is crucial. Different engines require specific characteristics in a connecting rod. For instance, high-performance engines often benefit from lightweight materials like titanium. This reduces inertia and enhances throttle response. Meanwhile, heavy-duty engines might need steel rods for strength and durability. Each application has its unique needs.

Tip: Consider the engine’s maximum RPM. Higher RPMs require rods designed for stress. If a rod isn't strong enough, it can fail under pressure. Weighing options can be daunting. A well-selected rod can boost power and efficiency.

Another factor to keep in mind is the engine's configuration. V8 engines may use longer rods to maintain proper geometry. In contrast, smaller engines might use shorter rods. The design affects torque and horsepower delivery.

Tip: Pay attention to the weight. A rod that's too heavy can slow down the engine. It’s important to strike a balance between strength and weight. Reflect on what performance you truly need. Focus on both immediate needs and long-term durability.