+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

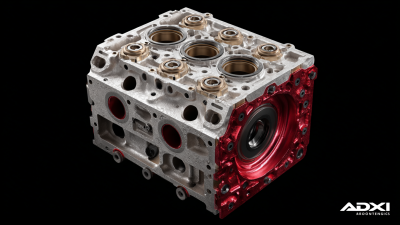

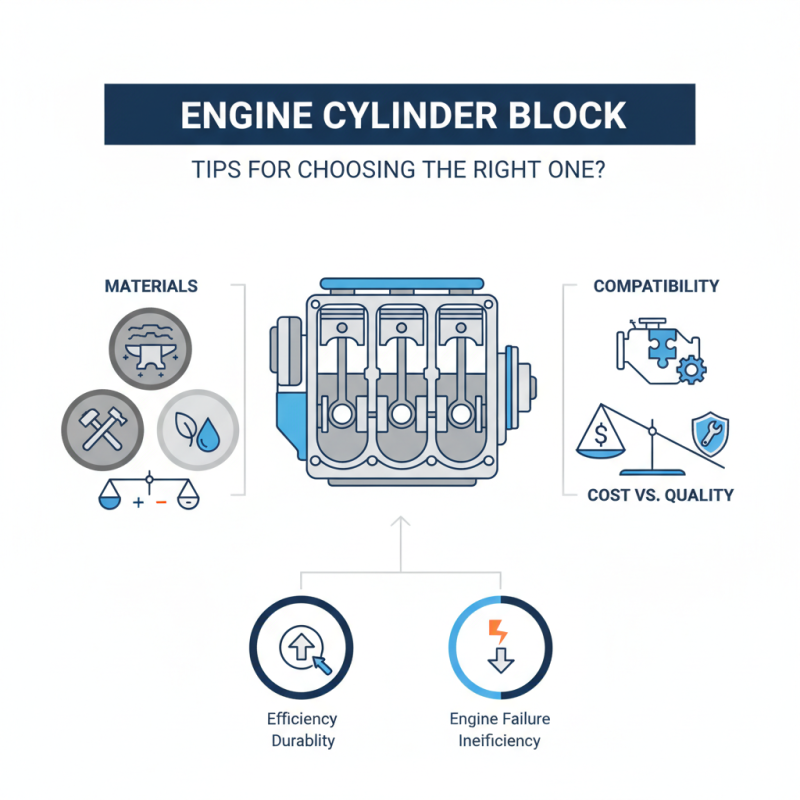

Choosing the right Engine Cylinder Block is crucial for your vehicle's performance. This component serves as the foundation of the engine. It houses vital parts, such as pistons and crankshafts. A good block can enhance efficiency and durability. However, not all blocks are created equal.

When selecting an Engine Cylinder Block, consider various factors. Materials play a significant role. Options range from cast iron to aluminum. Each material has its pros and cons. For example, aluminum is lighter but may not handle heat as well. This can lead to potential issues down the line.

Moreover, compatibility with your engine type is essential. Mismatched components can cause serious problems. A common pitfall is overlooking manufacturer specifications. This oversight can result in inefficiency or even engine failure. Balancing cost and quality can be tricky. It’s easy to get lost in options. Take your time and ask questions. Remember, this decision impacts your vehicle's future.

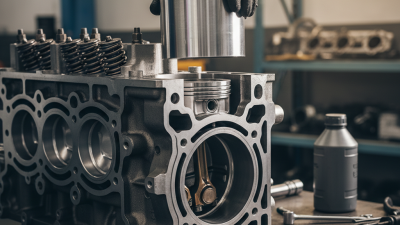

When selecting an engine cylinder block, understanding its structure is vital. The cylinder block is a core component of an engine. It houses pistons and supports engine operations. According to a recent industry report, over 60% of engine failures trace back to block issues. Engineers worry about material strength and heat dissipation.

Choosing the right block comes with challenges. Different materials, like aluminum and iron, offer varying qualities. Some blocks are lightweight, while others provide more durability. Evaluate your needs first. Consider the intended use of your vehicle. For high-performance engines, aluminum might be best for speed. For heavy-duty applications, iron could offer desired strength.

Tip: Always check for superior craftsmanship. A poorly made block can lead to serious problems, like leaks and reduced performance. Second tip: Consult industry standards and prefer blocks that meet rigorous quality checks. These steps can help avoid costly mistakes down the road.

Choosing the right engine cylinder block requires careful consideration of key factors. One primary aspect is material selection. Common materials include cast iron and aluminum. Cast iron offers durability but may add weight. In contrast, aluminum is lighter but could compromise strength in high-performance contexts.

Thermal expansion characteristics also impact performance. According to industry reports, proper thermal management is crucial for optimal engine performance. Engine blocks that can handle thermal fluctuations minimize the risk of warping. This consideration is particularly vital in high-stress environments, where engine failure could occur.

Another factor is the manufacturing process. Precision casting results in denser and more reliable blocks. A report from the Automotive Engineering Society indicates that high-precision manufacturing can enhance engine efficiency by up to 15%. Neglecting this can lead to subpar performance and longevity issues. The alignment, surface finish, and other details all play significant roles in the overall effectiveness of the engine block. These factors should not be overlooked when making your decision.

When selecting an engine cylinder block, material choice plays a crucial role. Engine blocks are typically made from cast iron or aluminum. Cast iron is known for its durability and excellent wear resistance. It can withstand high temperatures and pressures. According to the Engine Builders Association, cast iron blocks account for over 70% of all engines produced due to their reliability.

Aluminum blocks are lighter and provide better heat dissipation. They offer weight savings, which can improve fuel efficiency. However, aluminum is more susceptible to warping under extreme heat. Industry reports indicate that approximately 25% of high-performance engines now use aluminum blocks. This shift reflects a growing trend toward enhanced performance.

Each material has trade-offs. A lighter engine can lead to better acceleration but may sacrifice long-term durability. Choosing the right material involves balancing these factors. Using the wrong material might result in overheating or premature wear. This can affect overall engine performance significantly, sometimes requiring costly repairs. Think carefully about the application and driving style.

| Material | Density (g/cm³) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Manufacturing Cost |

|---|---|---|---|---|

| Cast Iron | 7.0 | 40 | Good | Low |

| Aluminum | 2.7 | 235 | Moderate | Moderate |

| Steel | 7.85 | 50 | Good | High |

| Composite | 1.5 | 25 | Excellent | High |

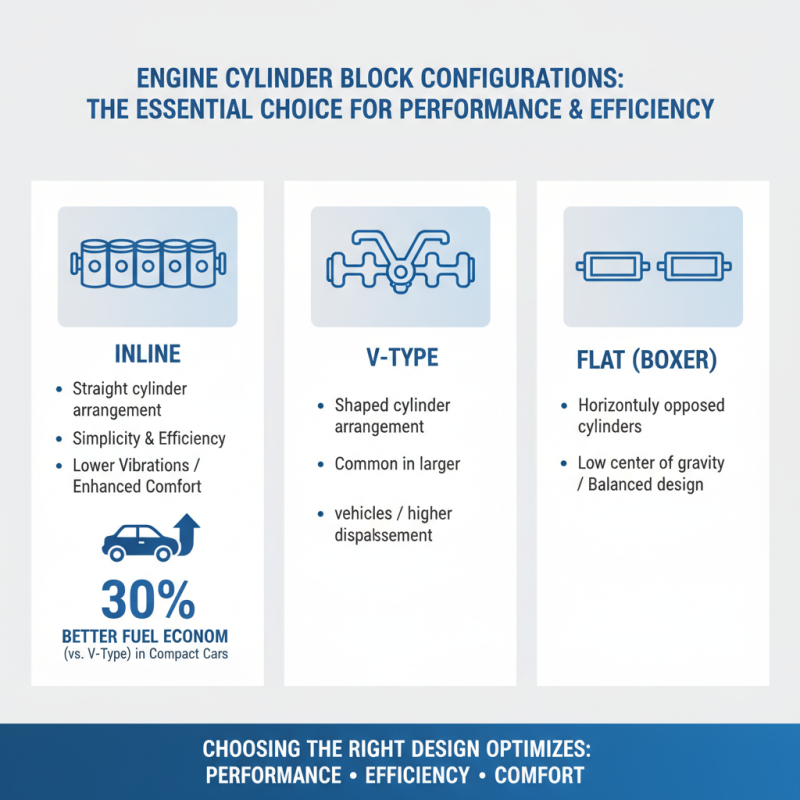

Choosing the right engine cylinder block is essential for performance. Among the most common configurations are inline, V-type, and flat designs. Inline engines, with straight cylinder arrangements, offer simplicity and efficiency. They often produce lower vibrations, enhancing comfort during driving. Data shows that inline configurations are prevalent in compact cars, helping achieve up to 30% better fuel economy compared to V-type engines.

V-type blocks, like V6 and V8, are well-known for power. They occupy less space than inline designs while providing greater power output. Research suggests that V6 engines can deliver 15% more torque than their inline rivals. However, this comes with increased complexity and potential maintenance concerns. Owners must be ready for more expensive repairs due to tighter engine compartments.

Flat engine designs, such as boxer engines, provide a low center of gravity. This enhances stability and handling. However, they can be harder to service, making routine maintenance a challenge. Choosing a block isn't just about power. It's about weighing performance against practicality. Each configuration presents unique benefits and drawbacks that require careful consideration.

When it comes to engine cylinder blocks, maintenance plays a crucial role in their longevity. A well-maintained cylinder block can last over 200,000 miles according to industry reports. Regular inspections are essential. Look for cracks or signs of corrosion. Even small issues can lead to significant problems later.

Engines operate under extreme conditions. Overheating is a common culprit for block damage. The engine’s cooling system should be checked often. Ensure the coolant is at the right level and free of contaminants. Proper oil changes are also vital. Dirty oil can wear down components and lead to costly repairs. Aim for oil changes every 3,000 to 5,000 miles, depending on the vehicle type.

Many owners underestimate the importance of torque specifications during assembly. Using incorrect torque can cause warping or misalignment. Professional guidelines recommend using a torque wrench for accurate measurements. Such precautions might seem tedious but can prevent future headaches. Remember, a little attention now can save big later.

This chart illustrates the estimated durability lifespan of various engine cylinder block materials. Understanding these differences can assist in making informed choices for maintenance and longevity of the engine components.