+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Upgrading your engine is a decision that can significantly enhance performance and efficiency. One of the pivotal components in this process is the connecting rod, a crucial element that connects the piston to the crankshaft. Selecting the right connecting rod is essential for ensuring that your engine can handle increased power and torque demands while maintaining reliability and durability. In this guide, we aim to provide you with ultimate tips to assist you in making an informed decision about connecting rods for your engine upgrade.

Understanding the nuances of connecting rods—such as materials, sizes, and designs—can be overwhelming, yet it is vital for achieving the desired performance gains. The ideal connecting rod must not only fit your engine specifications but must also align with your performance goals, whether that be optimizing for street use, racing, or heavy-duty applications. By delving into factors such as strength-to-weight ratio, rod length, and overall construction, you can better evaluate which connecting rod will best suit your unique engine setup. Through this exploration, our aim is to equip you with the knowledge to confidently choose the connecting rod that complements your engine upgrade and elevates your vehicular experience.

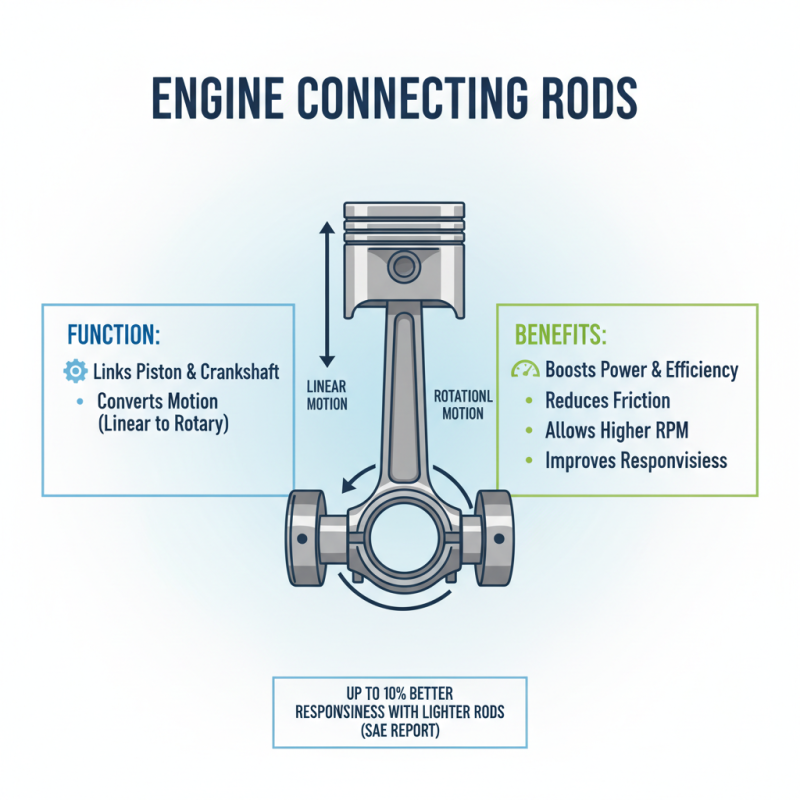

Connecting rods are a critical component in the internal combustion engine, serving as the link between the piston and the crankshaft. Their primary function is to convert the linear motion of the piston into the rotational motion needed to turn the crankshaft. This transformation is vital for energy efficiency and overall engine performance. An optimized connecting rod can reduce friction and enable the engine to rev higher without risking damage, thereby enhancing both power output and reliability. According to a report by the Society of Automotive Engineers, lighter connecting rods can improve the engine's overall responsiveness by up to 10%, showcasing their substantial impact on performance metrics.

The material and design of connecting rods play a significant role in determining engine performance. High-strength materials, such as forged steel and aluminum alloys, offer increased durability while minimizing weight. A study published in the Journal of Mechanical Engineering highlighted that connecting rods fabricated from advanced composites can withstand higher stress levels, thus prolonging service life and maintaining engine integrity under rigorous conditions. As engineers increasingly prioritize weight reduction and strength in engine design, understanding the properties of connecting rods becomes paramount for any significant engine upgrade. Selecting the right connecting rod not only adheres to performance expectations but also aligns with the broader goals of efficiency and longevity in modern engines.

When choosing the right connecting rods for an engine upgrade, selecting the appropriate material is paramount. Common materials for connecting rods include steel, aluminum, and titanium, each offering distinct advantages and drawbacks. Steel rods, often made from alloys such as 4340, are known for their strength and fatigue resistance, making them a popular choice for high-performance applications. According to industry reports, the tensile strength of 4340 steel can reach up to 1,200 MPa, which ensures reliable performance under severe conditions.

On the other hand, aluminum connecting rods, while lighter than steel, may not provide the same level of strength, typically reaching tensile strengths around 500 MPa. However, they are beneficial in applications where weight reduction is critical, leading to better engine responsiveness. Recent studies indicate that using aluminum rods can result in a 20% weight reduction compared to steel options, which can enhance performance in racing applications.

Titanium rods represent the cutting edge of connecting rod materials, combining the lightness of aluminum with the strength of steel. With tensile strengths often exceeding 900 MPa, titanium offers an excellent solution for those seeking both performance and durability. Yet, the cost and manufacturing complexity associated with titanium make them less accessible for many enthusiasts. Understanding these material characteristics can significantly influence the success of an engine upgrade, ensuring compatibility with the desired performance goals.

When upgrading your engine, selecting the right connecting rod requires careful consideration of length and width to optimize performance and reliability. The length of the connecting rod is crucial; it affects the engine's stroke and piston speed. A longer rod can enhance the engine's efficiency by improving the angle between the rod and piston at top dead center, reducing side loading on the piston and promoting a smoother operation. Conversely, a shorter rod can increase the RPM potential, which is beneficial for high-performance applications. Therefore, determining the right length begins with understanding your engine's specific requirements and how they align with your performance goals.

Width, or thickness, of the connecting rod is also a critical factor. A wider rod can provide increased strength due to its greater material volume, capable of handling higher loads during engine operation. However, this also adds weight, which might not be ideal in every application. Balancing strength with weight is key; if your goal is to achieve high revs and performance, you may need a lightweight yet durable rod.

Tips:

1. Always measure the existing rod dimensions before making any upgrades, as this will help you select the appropriate sizes for your engine.

2. Consider the type of performance you're aiming for—street reliability versus high-performance racing—as this will heavily influence your choice of connecting rod dimensions.

Connecting rods play a crucial role in an engine's performance and efficiency, serving as the link between the piston and the crankshaft. When upgrading your engine, it’s essential to consider the various designs of connecting rods available, each offering unique benefits that can significantly impact your overall build. For instance, I-beam and H-beam connecting rods are among the most popular options, with I-beams being lighter and typically providing better performance for high-revving engines, while H-beams are known for their strength and durability, making them suitable for high-torque applications.

Another important design to consider is forged versus cast connecting rods. Forged rods generally offer superior strength and resistance to fatigue, making them ideal for high-performance setups that endure extreme conditions. On the other hand, cast rods can be more cost-effective and are suitable for standard applications where weight savings and high performance are not the primary goals. Ultimately, the choice of connecting rod will depend on your specific engine goals, the type of power you aim to achieve, and your budget, which is crucial for optimizing both performance and reliability.

When upgrading your engine, one of the crucial components to consider is the connecting rod. The decision often boils down to the balance between cost and quality. In this era of diverse aftermarket options, many enthusiasts may be tempted to choose the lowest-priced option to save money. However, it is crucial to remember that cheaper connecting rods may compromise strength, durability, and performance. A subpar rod can lead to catastrophic engine failure, which would ultimately result in much higher repair costs and a loss of time.

On the other hand, investing in high-quality connecting rods can yield significant long-term benefits. Quality rods are typically manufactured from superior materials, which enhances their resistance to stress and fatigue. This durability can be crucial for high-performance applications where the engine operates under greater loads and higher RPMs. Therefore, it is essential to weigh the initial outlay against potential future expenses and performance gains. Making an informed purchase decision will not only enhance your engine's performance but also ensure reliability and longevity, providing peace of mind that the connecting rods will withstand the rigors of your upgrades.