+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

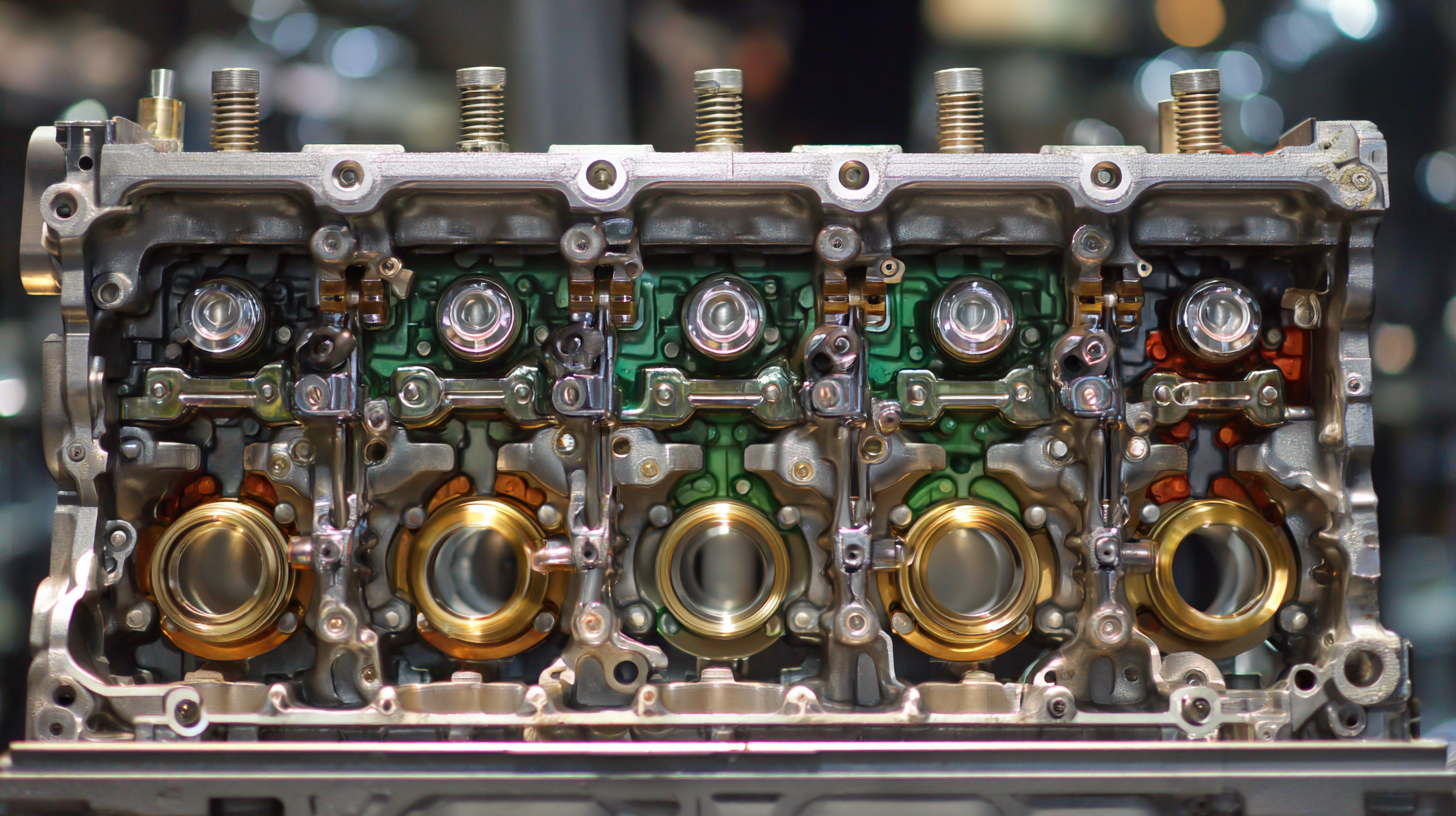

In the intricate world of automotive engineering, the significance of the cylinder liner in engine performance cannot be overstated. According to a report by the International Council on Clean Transportation, approximately 70% of an engine's efficiency can be attributed to its internal components, with the cylinder liner playing a crucial role in maintaining optimal compression and facilitating smooth movement of the piston. Cylinder liners not only provide a wear-resistant surface that supports the piston but also contribute to effective heat dissipation and engine longevity. As engine designs evolve and the demand for improved fuel efficiency and lower emissions rises, understanding the intricacies of cylinder liners has become essential for engineers and manufacturers alike. This blog will delve into the importance of cylinder liners, their types, and how they can directly impact overall engine performance.

Cylinder liners play a crucial role in enhancing the longevity and efficiency of marine engines. Recent studies indicate that the careful selection and installation of cylinder liners can lead to significant improvements in engine performance, with some reports showing efficiency gains of up to 10%. This is particularly important for marine engine operators, who are constantly seeking ways to reduce operational costs and extend the life of their equipment. The use of advanced materials in the manufacturing of these liners has contributed to reduced wear and tear, ultimately leading to longer service intervals and lower maintenance costs.

Moreover, the deployment of innovative design features in cylinder liners is pivotal in optimizing thermal efficiency. Engine builders are increasingly aware that proper sleeve installation is critical; suboptimal installation can lead to premature failures and increased downtime. A case study on a major marine engine overhaul revealed that engines fitted with high-quality cylinder sleeves experienced a 25% reduction in overhaul frequency when compared to traditional liners. As the marine industry evolves, the emphasis on the efficiency of componentry, including cylinder liners, becomes imperative for successful operations in competitive markets.

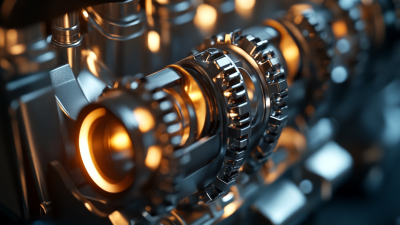

The cylinder liner is a crucial component of an engine that significantly impacts its overall performance. One of the key characteristics of cylinder liners is their material composition. Commonly made from cast iron or aluminum alloys, the choice of material can affect both the durability and thermal conductivity of the liner. High-quality materials can withstand extreme pressures and temperatures, contributing to better combustion efficiency and reduced wear over time.

Another important aspect is the thickness and design of the liner. A thicker liner can provide better support and longevity, especially in high-performance engines where stress and temperature fluctuation are more pronounced. Additionally, the inner surface finish plays a vital role in oil retention and reduced friction, which directly influences engine output and fuel efficiency. Ultimately, understanding these characteristics helps in selecting the right cylinder liner for specific engine applications, maximizing performance and reliability.

The thickness of cylinder liners plays a pivotal role in the overall performance of an engine, significantly impacting both fuel economy and emissions. A thicker cylinder liner may improve the durability of the engine components but can also alter the way heat dissipates within the engine. Studies have shown that maintaining an optimal thickness is key to ensuring efficient fuel combustion and reducing harmful emissions. This balance is essential for engines operating on various fuel types, including biodiesel blends, where the interaction between fuel properties and liner thickness can lead to varied exhaust outcomes.

When considering the performance of a cylinder liner, operators should ensure consistent monitoring of operating temperatures. High temperatures can heighten frictional losses, exacerbating emissions, particularly hydrocarbon (HC) and nitrogen oxide (NOx) output. Engine designers must be meticulous in selecting materials and coatings for cylinder liners to optimize their thermal properties and minimize adverse environmental effects.

**Tips:** Regular maintenance of engine components is crucial to sustain optimal cylinder liner performance. Additionally, experimenting with different fuels can help identify blends that work best with specific engine designs. Lastly, consider advancements in thermal barrier coatings to enhance the efficiency of your engine and reduce emissions.

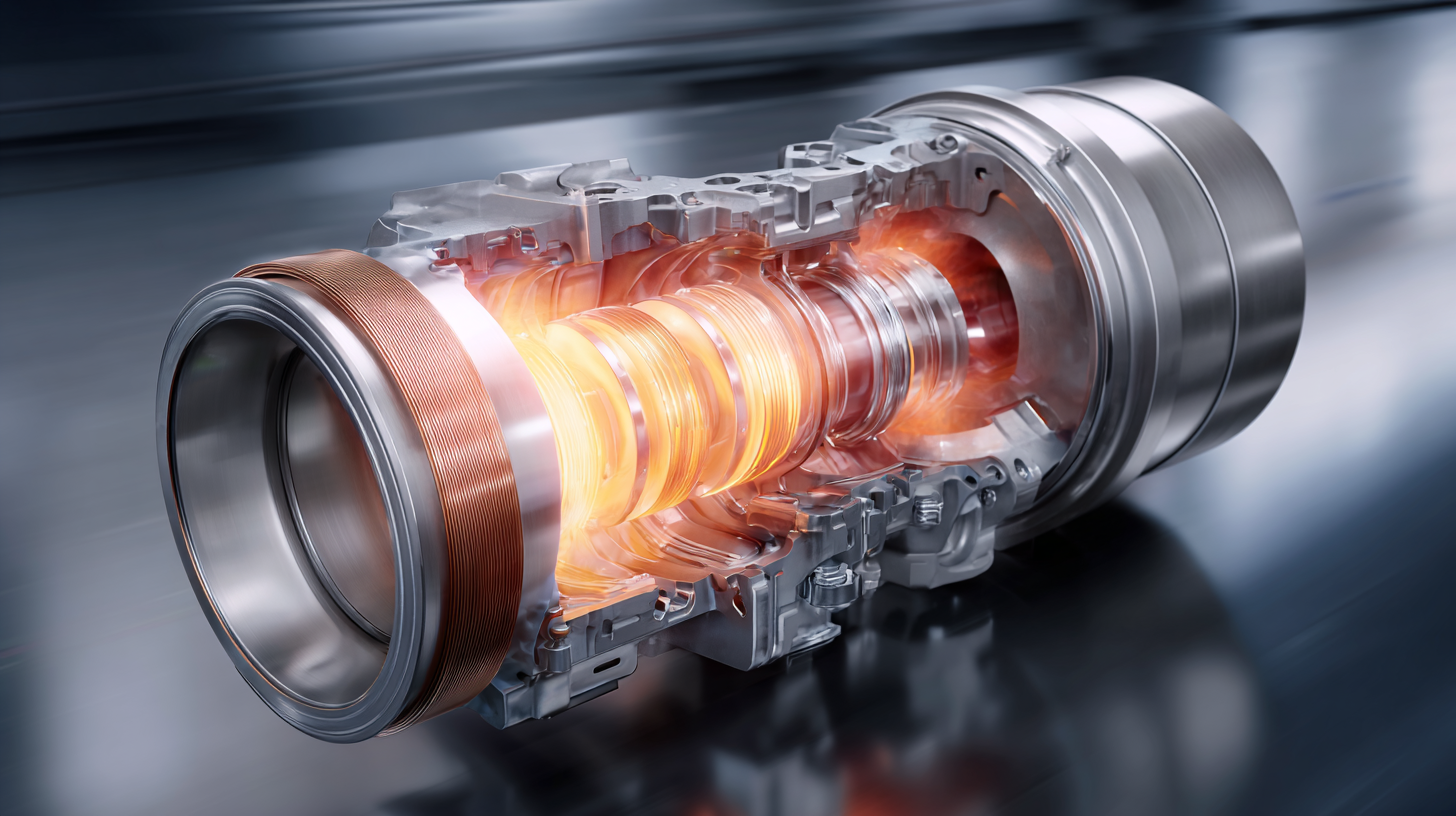

When it comes to enhancing engine performance, the materials used for cylinder liners play a crucial role. Cylinder liners can be fabricated from a variety of materials, each offering distinct advantages and specific performance metrics that can significantly affect overall engine efficiency. The most common materials include cast iron, aluminum, and composite materials, each chosen based on the engine's design requirements and expected operating conditions.

Cast iron is traditional in many engines due to its durability and wear resistance. It provides excellent thermal conductivity, helping to dissipate heat efficiently during operation. However, as engines strive for lighter components to improve fuel economy, aluminum liners have gained popularity. Aluminum’s lower weight aids in reducing the overall engine mass, leading to better acceleration and responsiveness. Additionally, advancements in machining techniques have improved the performance metrics of aluminum liners, allowing for close tolerances and a smoother finish that can enhance sealing and reduce friction.

In recent years, composite materials have emerged, combining the lightweight advantages of aluminum with the toughness of cast iron. These liners often incorporate elements like ceramic coatings or polymer composites, delivering superior wear resistance and thermal stability. Such innovations allow manufacturers to push the boundaries of performance, resulting in engines that can sustain higher power outputs while maintaining reliability. By understanding these materials and their performance metrics, manufacturers can better meet the demands of modern automotive applications.

Maintaining the cylinder liner is crucial for enhancing engine performance and prolonging its lifespan. Regular inspections can help identify early signs of wear or damage, such as scoring or pitting, which can adversely affect engine efficiency. A thorough cleaning process, removing carbon deposits and contaminants, should be part of routine maintenance to ensure the liner operates smoothly. Additionally, monitoring oil quality and levels is essential, as proper lubrication reduces friction and minimizes wear on the liner surfaces.

Using high-quality lubricants and ensuring they are changed at recommended intervals can significantly optimize the functionality of the cylinder liner. Implementing a proper break-in procedure for newly installed liners is also vital, as it sets the foundation for effective sealing and reduces the risk of premature failure. Ultimately, adopting these maintenance tips not only enhances the durability of the cylinder liner but also contributes to overall engine performance, providing better fuel efficiency and reduced emissions.