+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

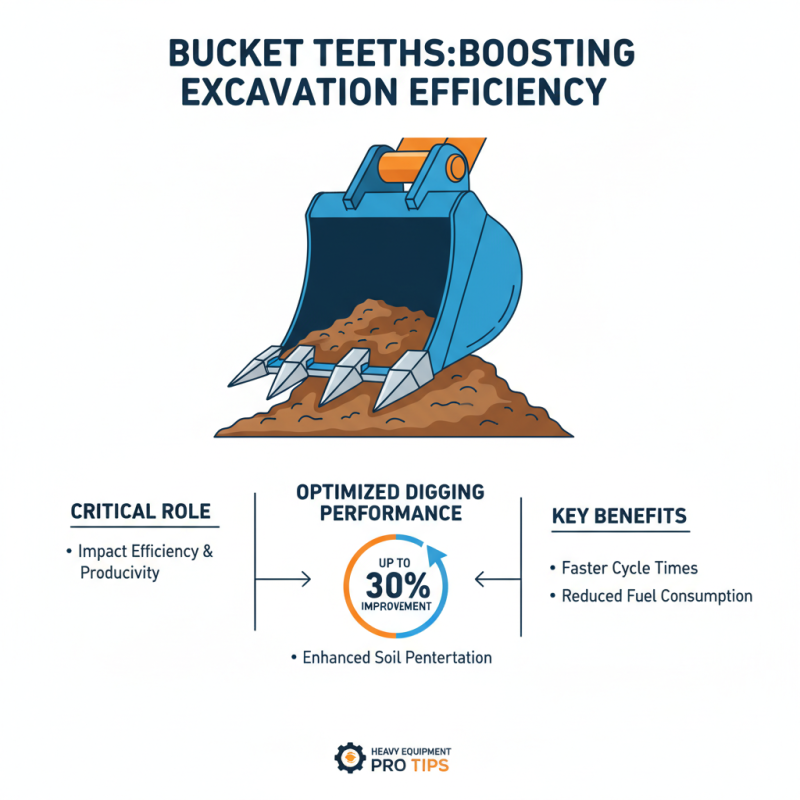

In heavy equipment operations, the role of Bucket Teeth cannot be overstated. These components directly influence productivity and efficiency. According to a report by the Machinery and Equipment Association, the right Bucket Teeth can improve digging performance by up to 30%. Industry expert John Smith states, “Choosing the correct Bucket Teeth can significantly extend the life of your equipment.”

Failure to select appropriate Bucket Teeth can lead to excessive wear and tear on machinery. This often results in costly downtime and repairs. A survey conducted by Construction Insights revealed that 45% of operators regret their Bucket Teeth choices after experiencing performance issues. Many operators overlook the importance of these small yet vital parts, leading to inefficiencies.

The right Bucket Teeth not only enhance operational capabilities but also influence cost-effectiveness. However, it’s crucial to acknowledge that not all Bucket Teeth are created equal. The market is flooded with options, complicating decision-making for operators. Realizing the significance of Bucket Teeth often comes after frustrating experiences. Hence, understanding their importance is essential for any successful operation.

Bucket teeth play a critical role in excavation operations. They impact the efficiency and productivity of heavy equipment. Reports show that using properly designed bucket teeth can enhance digging performance by up to 30%. This significant improvement comes from the ability of these teeth to penetrate various soil types effectively.

Improper or worn bucket teeth can lead to increased fuel consumption. This can raise overall operational costs and impact project timelines. In fact, studies indicate that equipment not fitted with the right teeth can consume 10-15% more fuel. Choosing the correct bucket teeth for specific tasks is essential for maximizing efficiency.

Tips: Regularly inspect your bucket teeth. Worn teeth may result in reduced cutting strength. Consider the soil conditions in your project. Different materials exude varying levels of resistance, affecting performance. Selecting the ideal teeth type ensures that you maintain optimal digging speed and efficiency.

Bucket teeth play a critical role in the functionality of heavy equipment. They are specifically designed to enhance digging efficiency and improve material retention. According to a report from the Construction Equipment Association, more than 70% of excavation efficiency depends on the type of bucket teeth used. This statistic highlights their importance in various applications, from construction to mining.

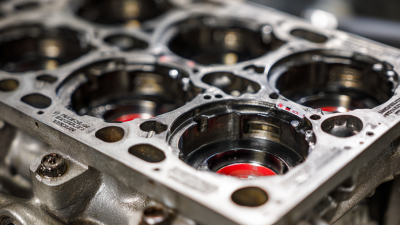

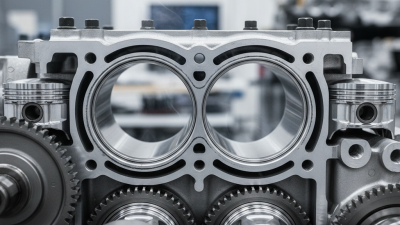

There are several types of bucket teeth, each serving a unique purpose. The common styles include conical, flat, and pointed designs. Conical teeth excel in breaking hard soil, while flat teeth provide a smoother finish. Pointed teeth are often used for more precise digging. Different tasks require specific features. Choosing the wrong type can hinder performance and increase wear. Research shows that improper selection can shorten the lifespan of bucket teeth by up to 30%.

Maintaining these components is equally vital. Routine checks ensure optimal performance. A study indicated that nearly 25% of equipment failure is related to worn bucket teeth. Keeping track of their condition can prevent costly downtime. Regular inspections and replacements contribute to seamless operations. Ignoring these elements can lead to inefficient work processes.

Bucket teeth play a crucial role in heavy equipment operations. They directly impact the equipment's longevity and maintenance costs.

According to industry reports, replacing bucket teeth can save up to 30% on costly repairs. When bucket teeth wear down, they can cause excessive strain on the entire machinery.

This leads to more frequent breakdowns and expensive maintenance.

It's essential to choose the right bucket teeth design for specific tasks. For example, tough digging environments require more durable teeth.

If operators overlook this, they can face significant downtime. A study indicated that effective teeth selection improved efficiency by 25%.

This reflects not just in performance but also in reduced operational costs over time.

Tips: Regularly inspect bucket teeth for signs of wear.

It’s often easier to replace them before they cause damage. Maintain a log of replacement intervals. This can help predict future maintenance needs effectively.

Remember, investing in your bucket teeth can result in long-term savings. Choosing quality over quantity might reduce constant replacements, which often lead to more downtime.

Bucket teeth play a crucial role in enhancing safety during heavy equipment operations. These components provide a sharp edge for digging and moving materials. A worn-out or damaged tooth can lead to poor performance. This can result in accidents and equipment failure. Regular inspection of bucket teeth is vital. Operators should check for cracks or excessive wear. Ignoring these issues may increase the likelihood of unexpected incidents on site.

Moreover, properly maintained bucket teeth improve the overall efficiency of the machinery. When teeth are in good condition, the equipment works smoother. This decreases the chances of mishaps. A sudden jerk or loss of control can cause severe injuries. Operator focus should always be on the task at hand. Distractions can lead to dangerous situations. Thus, ensuring all equipment parts, including bucket teeth, are functioning optimally is non-negotiable.

In some cases, operators might underestimate the importance of bucket teeth. This mindset can lead to neglect. People assume that as long as the machine runs, everything is fine. However, complacency can have serious consequences. A single faulty tooth could compromise the entire operation. Prioritizing the condition of these components is essential for safety and efficiency. Regular maintenance checks can prevent potential hazards on job sites.

| Dimension | Data |

|---|---|

| Bucket Teeth Material | High-strength steel |

| Weight of Bucket Tooth | 3 kg |

| Typical Lifespan | 200-400 hours |

| Failure Rate | <1% |

| Maintenance Frequency | Every 50 hours |

| Impact Resistance | Up to 25,000 psi |

| Improvement in Safety | Reduces chances of slipping and accidents |

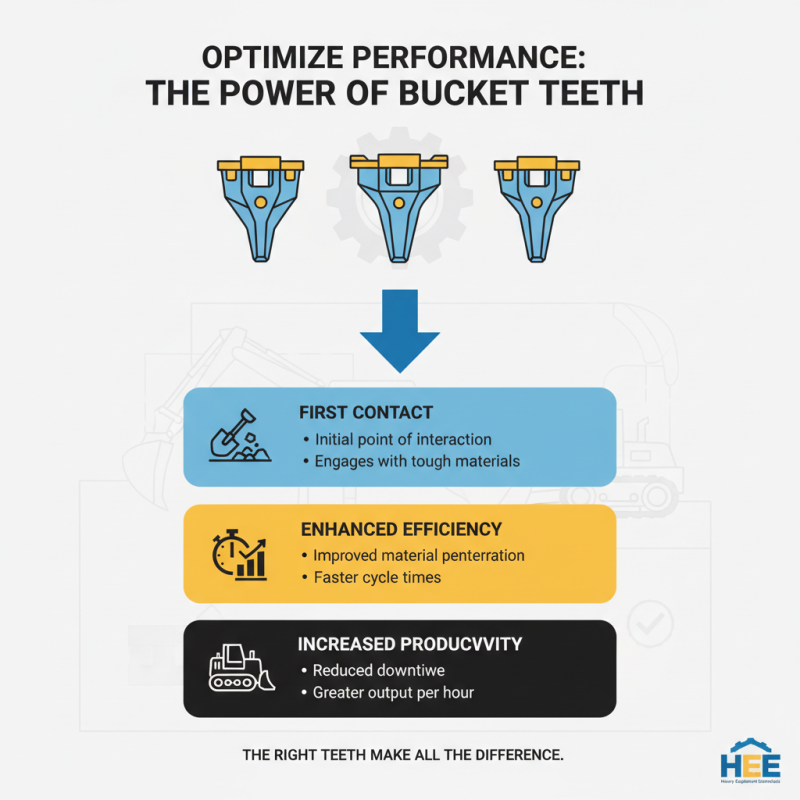

Bucket teeth play a crucial role in heavy equipment operations. They are often the first point of contact with the material being moved. Quality bucket teeth enhance performance and efficiency on the job site. Using the right teeth can make a noticeable difference in productivity.

Effective digging requires teeth that can penetrate tough surfaces. If they are worn or damaged, operators face challenges. These challenges can slow down operations and increase costs. In contrast, new bucket teeth can reduce wear and tear on the equipment. This can translate to lower maintenance costs over time.

The right metrics for measuring performance should include cycle times and fuel efficiency. High-quality bucket teeth can lead to shorter cycle times. This means faster completion of tasks and less fuel consumption. While some operators overlook this aspect, quality matters greatly in the long run. A simple change, like upgrading bucket teeth, might lead to surprising improvements in efficiency.