+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

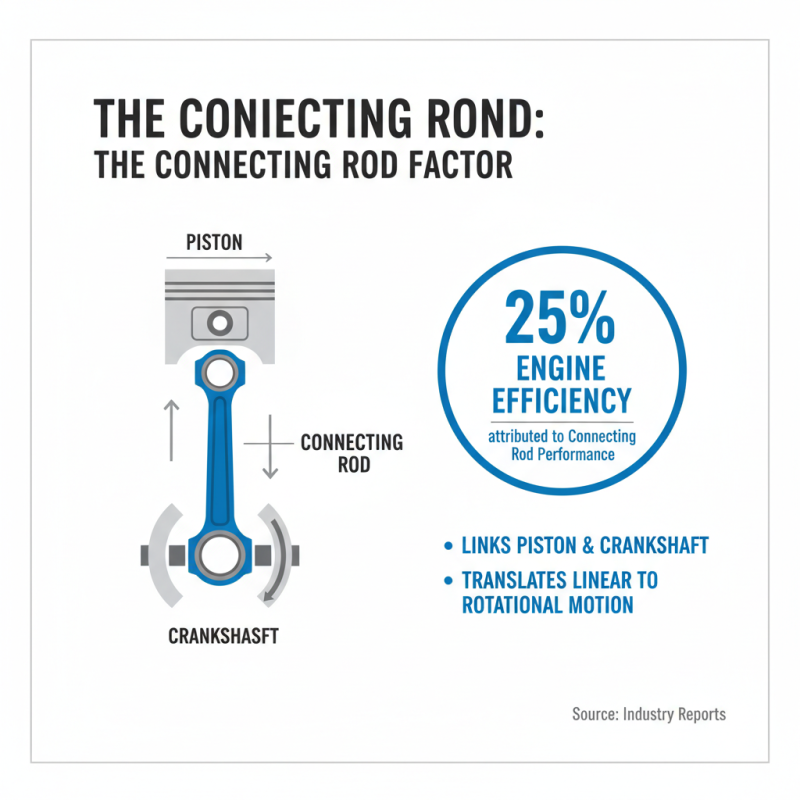

The engine is a complex machine, relying on various components to operate smoothly. Among these, the Connecting Rod plays a critical role. It connects the piston to the crankshaft, transforming linear motion into rotational movement.

If the Connecting Rod fails, the engine's performance suffers dramatically. A weak or damaged rod can lead to vibrations and reduced power output. This is not just a mechanical flaw; it can result in costly repairs.

Understanding the function of the Connecting Rod is essential for car owners and enthusiasts. It can enhance both performance and longevity. When maintenance is overlooked, issues may arise, highlighting the importance of regular inspections. The Connecting Rod, though often unnoticed, is key to a reliable engine.

The connecting rod plays a crucial role in internal combustion engines. It serves as the link between the piston and the crankshaft, translating linear motion into rotational motion. This conversion is essential for efficient engine operation. According to industry reports, nearly 25% of an engine's efficiency can be traced back to the performance of the connecting rod.

When a piston descends due to combustion, the connecting rod withstands immense pressure and force. A connecting rod must tensile strength to avoid bending. Engineers often opt for high-strength materials to address this challenge. However, even the best materials can fatigue over time. Reports show that premature failures can occur if designs do not account for stress distribution adequately.

The design of the connecting rod directly impacts the engine's overall performance. Factors like rod length and weight affect engine balance and vibration. An imbalance can lead to inefficiencies in fuel consumption. Some industry studies indicate that optimizing rod design could improve fuel efficiency by up to 5%. Yet, many manufacturers still struggle with these optimizations. Balancing performance with cost remains a persistent challenge in the industry.

The connecting rod plays a vital role in engine performance. It connects the piston to the crankshaft, converting linear motion into rotational motion. This function is crucial, as it drives the whole process of power generation. A well-designed connecting rod can enhance efficiency, ensuring smoother operation. However, imperfections can arise during manufacturing. Even minor flaws can lead to increased friction and decreased performance.

Beyond just connecting components, the connecting rod supports the engine's overall structure. It helps maintain alignment, which is essential for optimal operation. Misalignment can cause uneven wear and tear. This may lead to catastrophic failures over time. The material choice for connecting rods is also significant. Different metals provide different strengths and weights. A heavier rod may exert more force but at the cost of speed. Conversely, a lighter rod improves agility but may lack durability.

Regular inspection of the connecting rod is essential. Signs of wear should not be ignored. If not addressed, they can lead to severe engine issues. Making informed choices about maintenance can prolong engine life. However, each decision carries its own set of potential drawbacks. It’s crucial to weigh these carefully for optimal performance.

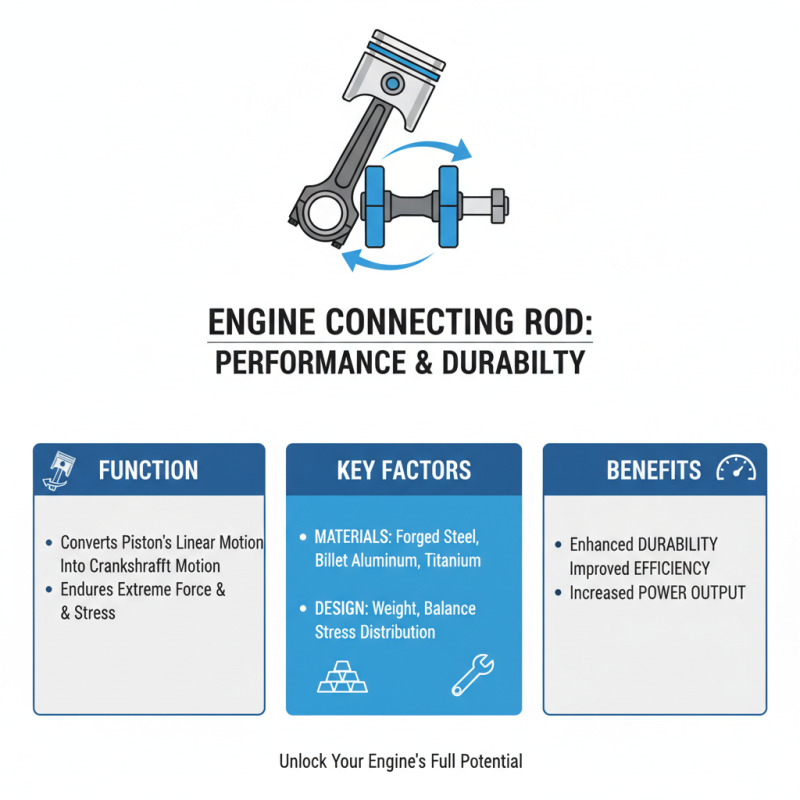

When it comes to engine performance, the connecting rod plays a vital role. It's designed to convert the linear motion of the pistons into rotational motion for the crankshaft. This part must endure significant force and stress. Understanding materials and design is crucial for enhancing durability and efficiency.

Connecting rods are commonly made from various materials. Common choices include steel and aluminum. Steel rods are strong and handle high loads well. Aluminum rods, on the other hand, are lighter. They improve engine response but may not endure the same stress levels. Balancing weight and strength is key.

Tips: Always consider the engine's purpose when selecting a connecting rod material. A racing engine might benefit from lighter options, while a heavy-duty engine may require the robustness of steel.

Design is equally important. A well-designed connecting rod ensures proper alignment and reduces wear. Shapes and sizes can influence how efficiently the engine runs. Small variations can lead to significant performance differences.

Tips: Analyze your engine's design requirements thoroughly. Experimenting with different designs may yield better results but can also lead to unforeseen problems. Constant feedback and testing are essential throughout the process.

The length of a connecting rod plays a vital role in engine dynamics. A longer rod can provide better leverage, reducing the angle of the piston's movement. This smoother motion allows for higher RPMs and increased efficiency. However, longer connecting rods can also add weight to the engine. This extra weight might impact overall vehicle performance.

On the other hand, shorter connecting rods can offer quick piston response. They lead to a steeper piston angle, causing more friction during operation. This could result in increased wear over time. Balancing these factors is critical. The choice of rod length must suit the specific application of the engine.

Engine designers often face tough choices regarding rod length. Every adjustment has consequences—both positive and negative. A precise calculation is necessary to optimize performance. Understanding these dynamics is essential for anyone involved in engine design or modification. Mistakes can lead to decreased efficiency or engine failure, making it crucial to reflect on decisions made during the design process.

The chart illustrates the impact of connecting rod length on engine efficiency. As the length of the connecting rod increases, the engine efficiency tends to improve, showing the critical role that the connecting rod plays in enhancing engine performance.

The connecting rod plays a crucial role in an engine’s performance. It transmits power from the piston to the crankshaft. If it fails, the engine may lose power or even seize up. In fact, studies show that nearly 30% of engine failures are due to issues with connecting rods.

Common problems include bending or breaking due to excessive stress. Often, improper lubrication exacerbates this wear. According to a report from the Society of Automotive Engineers, nearly 15% of connecting rod failures are linked to inadequate oil maintenance. This highlights the importance of regular oil changes and checks.

Maintenance should focus on inspecting for signs of wear or noise. The connection points must be well-lubricated to prevent friction. A visual inspection may reveal cracks or deformation. Regularly replacing worn-down components can save costs in the long run. Some engine builders recommend checking connecting rods every 50,000 miles, especially in high-performance scenarios. Ignoring these maintenance steps may lead to costly repairs and reduced engine efficiency.