+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

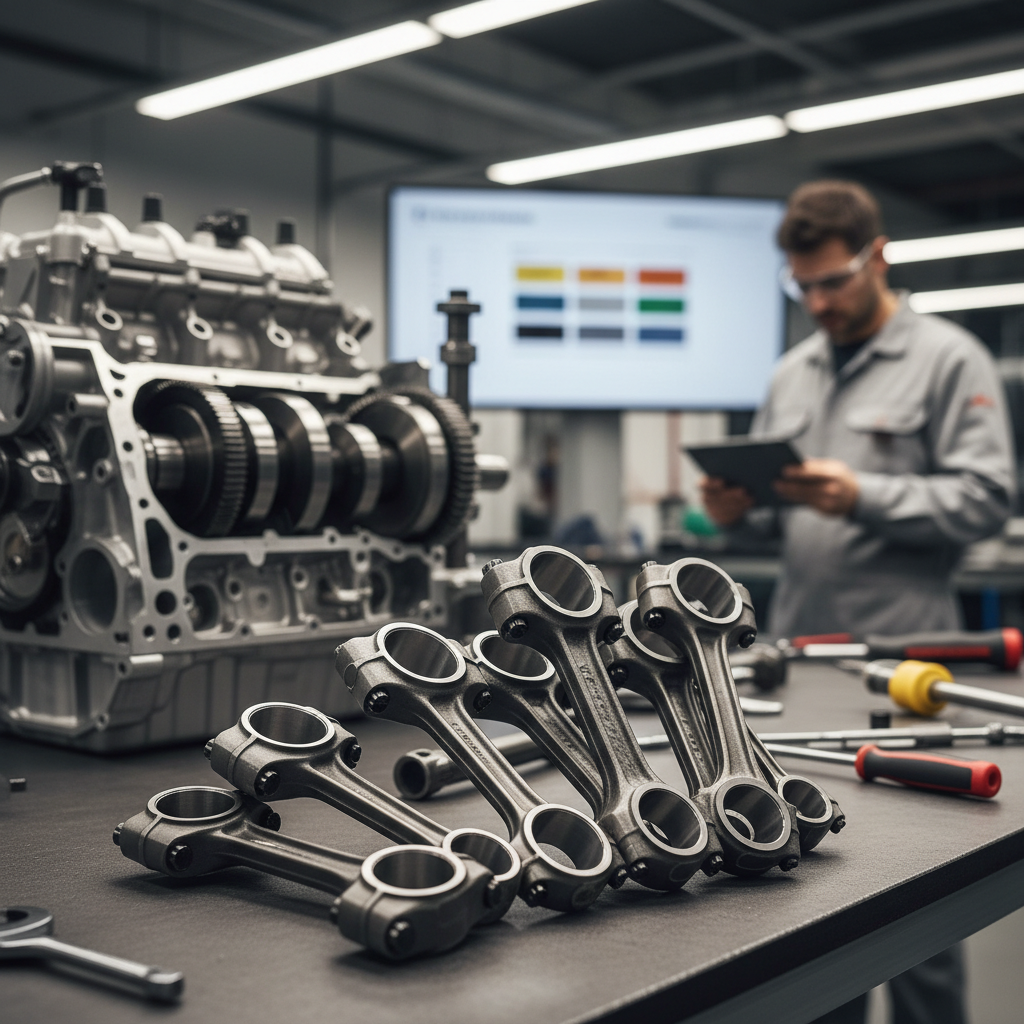

Selecting the right connecting rod is crucial for optimizing your engine's performance and longevity, especially in high-performance applications. As highlighted in the recent "2025 Top 10" automotive engineering report, the market for performance components, including connecting rods, is expected to grow significantly, projected to reach $1.5 billion by 2025. This growth is driven by advancements in materials and technology that enhance engine efficiency and power output.

Industry expert Dr. Lisa Chen, a leading authority on engine dynamics, emphasizes the importance of precision in this selection process. She states, "The connecting rod is not merely a component but a vital link that impacts the entire engine's responsiveness and reliability." Her assertion underscores the necessity for engine builders and automotive enthusiasts to carefully consider specifications such as weight, material, and design to match their unique performance goals.

Understanding these factors is essential for achieving an optimal balance between performance gains and durability, making the selection of the right connecting rod a pivotal decision in engine tuning and modification.

When selecting connecting rods for your engine, understanding the material is crucial due to the balance between strength and weight. Common materials include steel, aluminum, and titanium, each offering unique benefits and trade-offs. Steel rods are renowned for their strength and durability, making them suitable for high-performance applications. However, they can be heavier, which may negatively impact the engine's overall performance.

In contrast, aluminum connecting rods are lighter and can enhance engine responsiveness. However, they often fall short in terms of tensile strength compared to steel rods, making them less ideal for extreme performance needs. Titanium rods present a favorable middle ground, offering high strength with lower weight, but they're typically more expensive.

Tips: When choosing between materials, consider the engine application and the RPM range you anticipate. For engines that will experience high RPMs and power outputs, heavier-duty materials like steel might be necessary. Conversely, for applications prioritizing quick acceleration and responsiveness, opt for lighter materials. Always align your choice with your overall performance goals and budget constraints.

The length and stroke ratio of connecting rods play a crucial role in determining an engine's performance characteristics. The connecting rod length influences the angle at which the piston connects to the crankshaft during its stroke. A longer connecting rod reduces the side loading on the pistons, allowing for smoother motion and less friction, which can lead to increased efficiency and power output. Additionally, longer rods can enhance the engine's ability to produce torque at higher RPMs, making them particularly suitable for performance-oriented applications.

On the other hand, the stroke ratio—the ratio of the connecting rod length to the stroke of the crankshaft—significantly impacts engine dynamics. A higher stroke ratio typically results in a more favorable mechanical advantage, improving the engine's ability to convert linear motion into rotational motion. Engines designed with a higher stroke ratio often exhibit better throttle response and enhanced power delivery across a broader RPM range. However, it’s essential to balance these factors with other design aspects, such as engine weight and overall dimensions, to achieve optimal performance tailored to specific driving conditions and requirements.

When selecting connecting rods for high-performance engines, the debate between forged and cast options is crucial. Forged connecting rods are crafted from a single piece of metal, typically through a process that involves extreme heat and pressure, resulting in a denser and stronger material. According to a report by the SAE International, forged rods can withstand greater stress and fatigue, making them ideal for engines that operate at high RPMs and under rigorous conditions. They typically exhibit superior tensile strength, often exceeding 100,000 psi, which is essential for performance applications where durability is paramount.

On the other hand, cast connecting rods are produced by pouring molten metal into a mold, a process that is generally less expensive and efficient for mass production. While they offer adequate performance for many applications, they can have variances in strength and may be more prone to failure under extreme stress. A study by Engine Builder Magazine highlights that while cast rods can be suitable for lower-performance engines or those focused on cost-effectiveness, they usually fail to meet the demands of competitive racing or high-horsepower builds. Performance enthusiasts should weigh these factors carefully, considering their specific engine goals and the operational demands they will face on the track or the street.

When selecting a connecting rod for optimizing engine performance, it's crucial to understand how its design directly impacts RPM and power delivery. The configuration of a connecting rod affects the reciprocating motion of the piston, which in turn influences the engine's ability to reach higher RPMs efficiently. A lightweight and rigid connecting rod can minimize inertia, allowing the engine to rev faster and sustain higher speeds, which is particularly beneficial in competitive racing scenarios.

Furthermore, the material and construction of the connecting rod significantly affect the engine's power delivery characteristics. High-quality materials can withstand greater stresses, resulting in improved durability and reliability under extreme conditions. A well-designed connecting rod not only enhances the engine's power output but also ensures that the power is delivered smoothly across the RPM range. This balance is essential for achieving optimal performance in various driving conditions, making it imperative for engine builders to choose the right connecting rod tailored to their specific performance needs.

When selecting the right connecting rod for your engine, it’s essential to consider the engine's specific configuration and application to maximize performance. Different engine types, such as V6, V8, or inline configurations, have unique dimensional and load requirements. For instance, high-performance applications may benefit from lightweight, forged connecting rods that can withstand greater stress, while daily driving setups might prioritize durability and cost-effectiveness in their choice.

Furthermore, the intended use of the engine plays a significant role in this decision. Racing applications demand rods that offer both strength and reduced weight to improve rev response and overall efficiency. In contrast, rods for towing applications should focus on increased strength and reliability, capable of handling the high torque loads. By understanding the engine's operational environment and performance goals, you can select a connecting rod that not only enhances performance but also ensures longevity and reliability in your setup.