+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

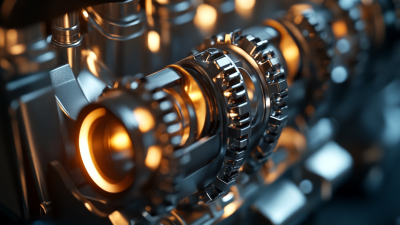

In the realm of performance upgrades for automotive enthusiasts, understanding the intricacies of Con Rod Bearings is paramount. These components play a critical role in the overall functionality and efficiency of an engine, especially when it comes to high-performance applications. As engines are pushed to their limits, the demands on the Con Rod Bearing increase, making the selection of the right type essential for maximizing power output and ensuring longevity.

This guide aims to provide a comprehensive overview of the top Con Rod Bearing types available in 2025, highlighting their unique features and benefits. From traditional bronze bearings to advanced composite materials, we will delve into what sets each option apart, considering both performance and durability. By the end of this article, readers will be equipped with the knowledge necessary to make informed choices about Con Rod Bearings for their specific needs, ensuring optimal engine performance and reliability in every application.

When considering performance upgrades for engines, understanding the differences between common con rod bearing types is crucial. Primarily, there are two main categories of con rod bearings: standard and performance bearings. Standard bearings are typically made from softer materials, designed for durability and longevity in everyday driving scenarios. However, for those looking to enhance engine performance, performance bearings are engineered with advanced materials and coatings that reduce friction and improve heat dissipation, enabling higher RPMs and better overall engine efficiency.

Another significant aspect is the clearance tolerance. Standard con rod bearings often have wider tolerances, catering to general usage and wear over time. In contrast, performance bearings are manufactured with tighter tolerances, which allows for improved oil control and stronger oil film stability under extreme conditions. This tighter fit enhances the responsiveness of the engine, making it ideal for racing or high-performance applications where every fraction of a second counts. Understanding these differences can lead to informed decisions when upgrading engine components for optimal performance.

When it comes to upgrading your engine's performance, selecting the right con rod bearings is crucial. Understanding the material choices available is vital for ensuring durability and efficiency under high stress. According to a 2022 SAE International report, high-performance con rod bearings are increasingly made from advanced materials such as bi-metal, tri-metal, and polymer composites. Each of these options offers distinct advantages suited for various applications.

Bi-metal bearings, for instance, typically consist of a steel backing and a soft alloy overlay, providing excellent load-bearing capabilities and resistance to wear. A study conducted by the Engine Research Center at the University of Wisconsin-Madison highlights that modern bi-metal bearings can withstand operating temperatures exceeding 150°C while promising a longer service life due to their lower friction characteristics. On the other hand, tri-metal bearings—composed of a steel backing, a copper-lead layer, and a tin overlay—are preferred for their superior fatigue resistance in extreme conditions, making them a popular choice in motorsport applications.

Furthermore, polymer composite bearings have emerged as a revolutionary option in the realm of high-performance applications. Their lightweight nature and exceptional chemical resistance provide an advantageous alternative for weight-sensitive projects. Research published in the Journal of Tribology indicates that polymer bearings can reduce friction by up to 50% compared to traditional metal bearings, showcasing their potential for enhancing engine performance. As manufacturers continue to innovate, understanding the strengths and weaknesses of these materials will be essential for anyone looking to optimize their engine's performance.

When upgrading con rod bearings, it's crucial to consider several key factors to ensure optimal performance and longevity. First, the material composition of the bearings plays a vital role. High-performance bearings are often made from stronger alloys or composite materials, which can withstand higher temperatures and pressures typically found in modified engines. Choosing the right material can lead to enhanced durability and reduced friction, allowing the engine to perform at its peak.

Another important factor is the size and fit of the bearings. Upgrading to a larger diameter bearing can increase load capacity, but it’s essential to ensure that the new bearings fit perfectly within the con rod and crankshaft. Mismatched sizes can lead to catastrophic engine failures. Additionally, understanding the engine's specific requirements, including the type of oil used and the anticipated RPM range, can guide the selection process. By carefully considering these elements, enthusiasts can make informed decisions that complement their performance upgrades and maximize engine efficiency.

| Bearing Type | Material | Max RPM | Load Capacity (lbs) | Cost Range ($) |

|---|---|---|---|---|

| Bi-Metal | Aluminum / Tin | 6000 | 1500 | 50 - 100 |

| Tri-Metal | Copper / Lead | 7000 | 2000 | 80 - 150 |

| Steel Backed | Steel / Bronze | 8000 | 2500 | 100 - 200 |

| Synthetic | Polymer | 9000 | 1800 | 150 - 300 |

To ensure the longevity and efficiency of con rod bearings, regular maintenance is crucial. One of the primary maintenance tips is to frequently check and maintain optimal oil levels. The right amount of high-quality engine oil plays a vital role in lubricating the bearings, reducing friction, and preventing overheating.

Additionally, using oil that meets or exceeds the manufacturer's specifications can further enhance performance and extend the life of the bearings.

Another essential tip is to monitor the engine's operating conditions. Overheating, excessive RPMs, or poor lubrication can lead to premature bearing wear. It’s beneficial to adhere to the manufacturer’s recommended service intervals and to perform regular inspections for signs of wear or damage. This proactive approach can help identify potential issues before they escalate, allowing for timely replacements and adjustments. Proper installation techniques also play a key role; ensuring that bearings are seated correctly during installation can prevent future complications and ensure optimal performance.

When choosing the right con rod bearings for your engine setup, understanding the specific requirements of your performance goals is crucial. Engine bearing technology has vastly improved, allowing for better durability and performance under extreme conditions.

High-performance bearings often feature advanced materials and designs that can significantly reduce friction and wear, leading to enhanced engine longevity and efficiency. Reports indicate that selecting the appropriate bearing can result in a reduction of friction by approximately 30%, resulting in noticeable gains in horsepower.

In addition to material selection, the compatibility of con rod bearings with your engine's crankshaft is essential. Many builders often overlook how closely these components interact; a well-matched crankshaft and bearing combination can lead to optimal performance gains. Factors such as load capacity and clearance tolerance should be carefully considered. Physical adjustments may also be necessary during installation to ensure perfect alignment and fitment, as even minor misalignments can lead to catastrophic failures. Therefore, meticulous attention to detail during both the selection and installation processes can yield significant improvements in both performance and reliability for your engine assembly.