+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the realm of industrial applications, the efficiency and effectiveness of machinery play a vital role in achieving optimal performance. Among the various components that contribute to these efficiencies, the bucket cylinder stands out as a critical element in a multitude of systems. Bucket cylinders are designed to provide powerful lifting and tilting capabilities, facilitating a range of operations from material handling to excavation. Their robust construction and versatility make them indispensable in several sectors, including construction, agriculture, and waste management.

The choice of bucket cylinder types can significantly impact the overall productivity of industrial processes. Different designs and specifications cater to varying operational needs, whether it's for hydraulic excavators, loaders, or specialized industrial machinery. Understanding the various top types of bucket cylinders can empower engineers and operators to select the most suitable option for their specific applications, ensuring enhanced performance, reliability, and cost-effectiveness.

As we delve into the exploration of the most efficient bucket cylinder types, this article aims to provide insights into their functionalities and advantages. By examining their applications across different industries, we can appreciate how these essential components drive efficiency and success in industrial operations.

Bucket cylinders play a pivotal role in various industrial applications, serving as vital components in machinery that require both lifting and lowering functionalities. These hydraulic cylinders are designed to convert hydraulic energy into mechanical force, allowing for the efficient manipulation of materials in settings such as construction, mining, and waste management. By utilizing bucket cylinders, industries can achieve increased productivity, as these devices are engineered to handle heavy loads while maintaining uniform motion and stability.

The importance of bucket cylinders in industrial environments cannot be overstated. They enhance operational efficiency by providing reliable and powerful lifting capabilities, thus reducing the time and effort required to move heavy objects. Additionally, these cylinders contribute to safety by ensuring that loads are securely managed, thereby minimizing the risk of accidents. As industries continue to evolve and seek optimized solutions for their operations, bucket cylinders remain a fundamental aspect, enabling businesses to meet the demands of modern workloads while maintaining safety and efficiency in their processes.

Bucket cylinders are integral components in a variety of industrial applications, offering mechanical power and efficiency in tasks ranging from lifting and lowering to pushing and pulling. Common types include single-acting and double-acting cylinders, each suited for different operational requirements. Single-acting cylinders are often used when only one direction of motion is needed, while double-acting cylinders provide force in both directions, making them ideal for tasks that require reversing movement without losing force.

In industries like construction and mining, bucket cylinders play a vital role in heavy machinery such as excavators and loaders. These cylinders must withstand significant pressure and ensure reliable operation under extreme conditions. Moreover, hydraulic bucket cylinders are favored for their ability to leverage hydraulic fluids to create powerful lifting capabilities, which increases operational efficiency and productivity.

Tips: When selecting a bucket cylinder for your industrial needs, consider the load requirements and the type of motion needed. Regular maintenance will also extend the lifespan of your bucket cylinders, reducing downtime and repair costs. Additionally, ensure compatibility with existing equipment to enhance overall operational efficiency.

Bucket cylinders play a crucial role in a variety of industrial applications, ranging from construction to waste management. These hydraulic devices are critical in lifting and controlling loads effectively, and choosing the right type of bucket cylinder is essential for optimizing performance. There are several key types, each with distinct features tailored to specific uses. For instance, double-acting bucket cylinders provide power in both directions (extend and retract), making them ideal for applications requiring precise control over the movement of heavy loads. According to industry reports, double-acting cylinders account for approximately 60% of the market share due to their versatile performance in demanding environments.

In terms of specifications, it's important to consider factors such as stroke length, bore size, and pressure rating when selecting a bucket cylinder. For example, standard bore sizes typically range from 2 to 12 inches, accommodating various load requirements. Additionally, the stroke length can vary significantly, with some models allowing for customized lengths to suit specific applications. Hydraulic pressure ratings commonly fall between 1,500 to 3,000 psi, depending on the cylinder design and intended use. Recent studies indicate that optimizing these parameters can lead to a 20-30% increase in efficiency and durability, significantly reducing operational costs over time. Understanding these features and specifications ensures industrial applications benefit from enhanced reliability and performance, driving forward productivity goals.

| Cylinder Type | Key Features | Specifications | Applications |

|---|---|---|---|

| Double Acting Cylinder | High efficiency, smooth motion, and easy installation | Bore size: 25-250 mm, Stroke length: up to 3000 mm | Material handling, automotive assembly, packaging |

| Single Acting Cylinder | Cost-effective, simple design, limited stroke control | Bore size: 32-200 mm, Stroke length: up to 1500 mm | Forklifts, agricultural machinery, compactors |

| Telescopic Cylinder | Space-saving, multi-stage extension, high force | Extended length: varies, Retracted length: custom | Dump trucks, aerial lifts, marine applications |

| Rotary Actuator | Rotational motion, compact design, high torque | Torque: up to 300 Nm, Rotation angle: up to 270 degrees | Assembly lines, automation, robotics |

| Compact Cylinder | Minimal design, lightweight, high performance | Bore size: 16-100 mm, Stroke length: up to 500 mm | Conveying, lift trucks, smaller machinery |

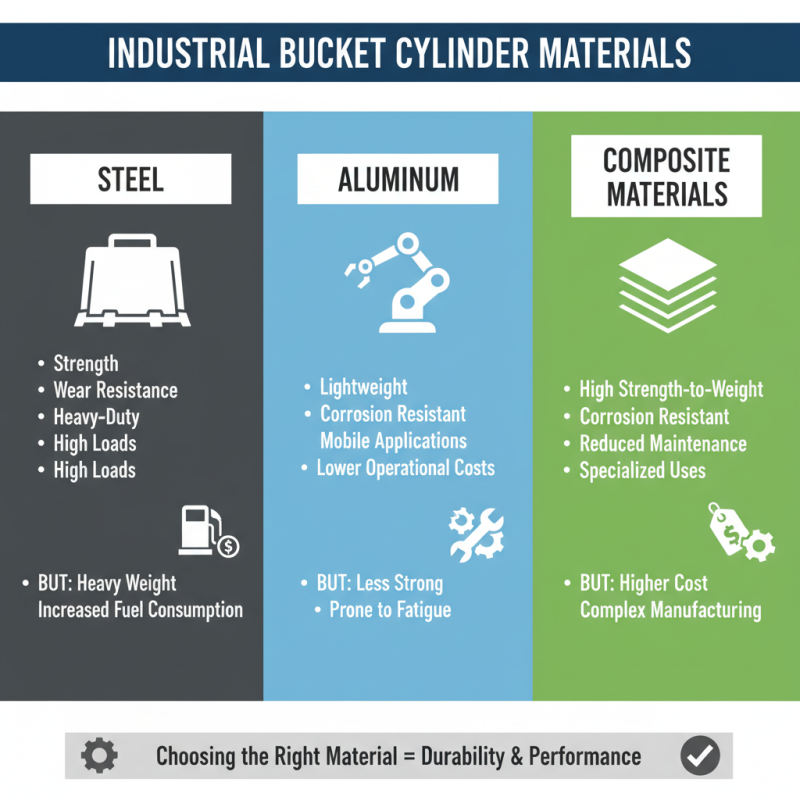

When selecting bucket cylinders for industrial applications, the choice of material plays a crucial role in determining durability and overall performance. Common materials for bucket cylinders include steel, aluminum, and composite materials. Steel is renowned for its strength and resistance to wear, making it a preferred choice in heavy-duty environments where high loads and frequent use are the norm. However, its weight can lead to increased fuel consumption and operational costs in mobile applications.

On the other hand, aluminum offers a significant reduction in weight, which enhances the efficiency of equipment. It provides adequate strength for moderate loads and is less susceptible to corrosion, making it suitable for environments where exposure to moisture and chemicals is a concern. Meanwhile, composite materials are emerging as a viable option due to their exceptional strength-to-weight ratio and resistance to environmental factors. They may offer advantages in specific applications, especially where minimizing maintenance and downtime is critical.

In comparative analyses, the durability of these materials under stress and extreme conditions is often measured. Factors such as fatigue resistance, impact absorption, and thermal stability are evaluated to determine the optimal choice for specific industrial needs. Ultimately, understanding these material properties and their performance in diverse environments can assist engineers and decision-makers in selecting the most efficient bucket cylinder for their applications.

Maintaining bucket cylinders is crucial for ensuring their longevity and optimal performance in industrial applications. Regularly inspecting the cylinder for wear and tear helps identify potential issues before they escalate into costly repairs or downtime. Key components, such as seals and bearings, should be checked for any signs of fatigue or damage. Keeping the hydraulic lines clean and free of contaminants is also essential, as debris can lead to system failures.

Implementing a scheduled maintenance plan that includes routine checks and timely replacements of worn parts can significantly enhance the reliability of bucket cylinders.

Optimization of bucket cylinder performance involves understanding the specific load requirements of the application. Adjusting the pressure settings according to the task at hand can prevent excessive strain on the components, extending their lifespan. Moreover, using appropriate hydraulic fluids that meet the operational demands can improve efficiency and reduce the chances of overheating.

Operators should be trained to recognize unusual noises or performance issues, as early detection allows for swift intervention. By combining thoughtful maintenance with performance optimization techniques, industrial operations can achieve higher efficiency and lower operational costs.