+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the world of construction and heavy machinery, "Boom Cylinders" play a critical role. According to John Smith, a leading expert in hydraulic systems, “The effectiveness of a machine often hinges on its boom cylinder’s design and application.” This statement highlights the importance of understanding different boom cylinder types. Each type caters to various applications, offering unique advantages.

Boom cylinders are essential for lifting, extending, and manipulating large objects. They enhance productivity and efficiency in construction, mining, and transportation. Yet, it's crucial to note that not all boom cylinders are created equal. Some are designed for specific tasks, while others offer versatility. Understanding these differences can lead to improved operational choices.

However, many industries overlook the complexities of selecting the right cylinder. Failing to consider load requirements or environmental factors can lead to inefficiencies. Operators often encounter challenges, making it essential to reflect on their choices. Recognizing the variety of boom cylinder types and their specific applications is vital for success in heavy-duty operations.

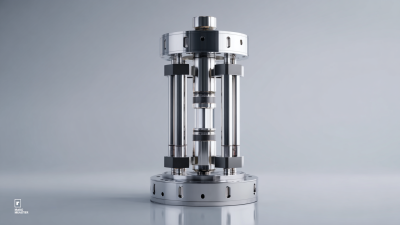

Boom cylinders are essential components in various machinery, providing the necessary force to lift and extend booms. Each type has unique features and specifications tailored for specific applications. Common types include single-acting, double-acting, and telescopic boom cylinders. Each type plays a vital role in industries like construction, forestry, and material handling.

Single-acting boom cylinders use hydraulic pressure for extension, relying on gravity for retraction. This design is simple and cost-effective. Double-acting boom cylinders operate in both directions, offering more control and power. Telescopic cylinders have segments that extend in stages, allowing a longer reach while maintaining a compact size when retracted.

**Tips:** Always consider the load capacity and required stroke length when selecting a boom cylinder. Maintenance is key. Regular inspections can prevent failures. Remember, not all applications require complex solutions. In some cases, simpler designs may offer the best reliability and performance.

| Boom Cylinder Type | Key Features | Specifications | Applications |

|---|---|---|---|

| Single Acting Cylinder | Simple design, low cost | Pressure: 2000 psi | Lifting loads in construction |

| Double Acting Cylinder | Higher lifting force | Pressure: 3000 psi | Excavators, cranes |

| Telescopic Cylinder | Compacts into small spaces | Stages: 2-5 | Boom lifts |

| Rotary Cylinder | Continuous rotation | Degrees: 360° | Material handling |

| Compact Cylinder | Space-efficient | Dimension: 20 mm bore | Tight spaces in machinery |

| Pneumatic Cylinder | Uses air pressure | Max Pressure: 100 psi | Automation systems |

| Hydraulic Cylinder | Powerful and efficient | Max Pressure: 4000 psi | Heavy machinery |

| Heavy Duty Cylinder | Durable, built for tough jobs | Capacity: 50 tons | Construction, mining |

| Miniature Cylinder | Small size for delicate tasks | Bore: 10 mm | Automation, robotics |

| Cushioned Cylinder | Soft landing feature | Cushion Length: 30 mm | Packaging machines |

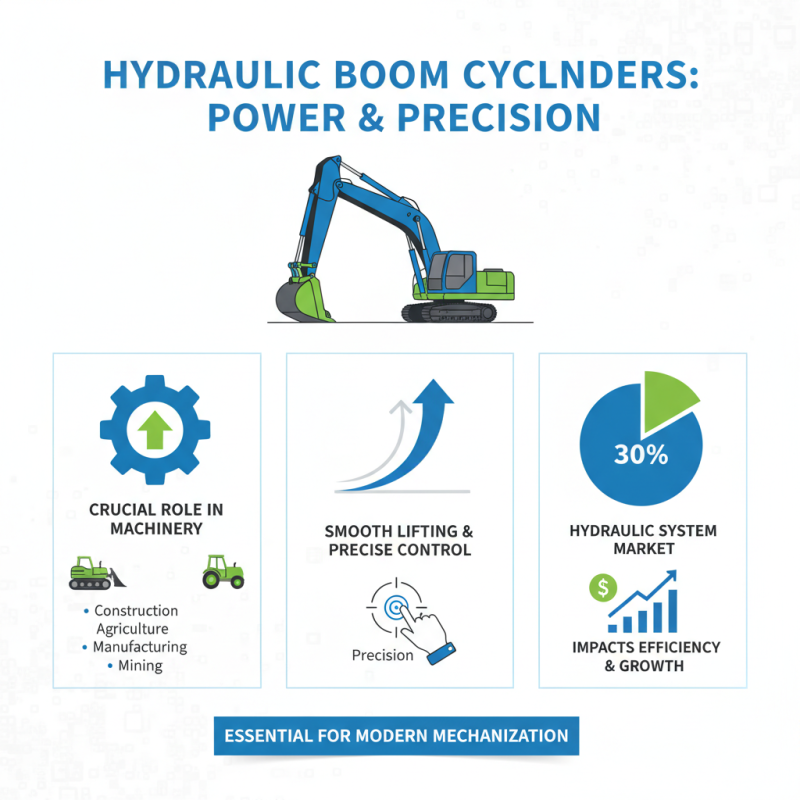

Hydraulic boom cylinders play a crucial role in various machinery sectors. These cylinders ensure smooth lifting and precise control. According to industry reports, hydraulic cylinders account for about 30% of the total hydraulic system market. Their efficiency impacts many applications, from construction to agriculture.

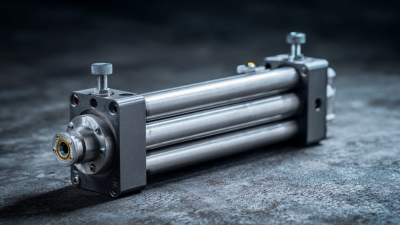

The functionality of these boom cylinders is defined by pressure and force. They operate under high pressure, achieving remarkable power in a compact design. For example, a standard hydraulic boom cylinder can exert up to 10 tons of force while retaining a lightweight structure. This makes them ideal for heavy-duty machinery. However, users must consider maintenance and potential failures. Undetected leaks can lead to significant performance drops and costly repairs.

Applications vary widely. In construction, boom cylinders enable cranes to lift heavy loads with stability. Agricultural machinery utilizes them for positioning implements, enhancing productivity. Yet, not every application integrates these cylinders seamlessly. Issues such as compatibility with other hydraulic components can arise, leading to operational inefficiencies. Improvement is always possible in design and function to meet evolving industry needs.

Pneumatic boom cylinders play a critical role across various industries. Their mechanisms rely on compressed air to create motion, making them ideal for heavy lifting tasks. According to a report by Grand View Research, the global pneumatic cylinders market size was valued at approximately $5.5 billion in 2020 and is expected to grow steadily. This highlights the increasing reliance on pneumatic systems.

One significant advantage of pneumatic boom cylinders is their lightweight design. This design allows for easy installation and maneuverability. Industries such as construction often use these cylinders for lifting and positioning materials. Their ability to work in harsh environments is another plus. However, they also come with limitations; for instance, they require a constant air supply. Interruptions can lead to functionality issues.

Use cases are abundant. In the automotive sector, pneumatic cylinders assist in manufacturing processes, such as assembly line functions. In warehousing, they help in loading and unloading goods. A challenge arises with energy efficiency. While pneumatic systems are useful, they can consume excess energy if not properly managed. This aspect needs further exploration for improvement.

Electric boom cylinders are transforming the landscape of modern equipment. These components provide precise control and efficient power. They are especially useful in heavy machinery. This innovation allows for smoother operation in various applications, from construction to material handling.

One key advantage of electric boom cylinders is their energy efficiency. They consume less power compared to traditional hydraulic systems. This reduces operational costs and environmental impact. However, challenges exist. The initial investment can be high. Additionally, maintenance requires specialized knowledge. Not all operators are equipped for this transition.

Another area to consider is adaptability. Electric boom cylinders can integrate with automation systems. This enhances productivity in factories and warehouses. Yet, not every application benefits equally. Some equipment still relies heavily on hydraulic systems. The balance between old and new technologies needs careful evaluation. Proper training and planning will aid this transition.

This chart illustrates the applications of various boom cylinder types, showcasing the number of uses across different sectors. Electric boom cylinders lead in applications due to their innovation and efficiency, followed by hydraulic and pneumatic types.

Choosing the right boom cylinder is crucial for achieving optimal performance in machinery. One key factor is the cylinder's lifting capacity. It must meet the specific weight requirements of your operation. Oversized cylinders can lead to inefficiencies. Conversely, undersized ones may risk damage.

Another important consideration is the operating pressure. Higher pressures can improve performance but may also increase wear and tear. Using a cylinder beyond its pressure limits can shorten its lifespan. Select models that are designed for your typical working conditions. An incorrect match could lead to frequent breakdowns.

Material and build quality also play significant roles. Some environments are harsher than others. Corrosion-resistant materials may be necessary for those conditions. Analyze the interaction between the cylinder and its attachments. Misalignment can cause malfunction or premature failure. Pay attention to all these factors for better functionality and reduced maintenance costs.