+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Choosing the right Bucket Teeth is a critical decision for machinery operators. According to industry expert John Smith, “The right teeth can make or break your productivity.” Understanding the function and specifications of Bucket Teeth can significantly impact performance.

When selecting Bucket Teeth, consider your machinery type and work environment. Different applications require different designs. Some teeth are tough for excavation, while others are meant for lighter work. Pay attention to wear patterns and material quality. This knowledge gives insight into longevity and efficiency.

Yet, it's common to underestimate these factors. Many operators still rely on generic options. This can lead to frequent replacements and increased costs. Reflecting on your choices can reveal areas for improvement. Proper selection of Bucket Teeth not only fuels efficiency but also saves time and money.

Choosing the right bucket teeth is vital for enhancing machinery performance. The right fit ensures effective digging and material handling. Incorrect teeth can lead to equipment strain, which often results in costly repairs and downtime. Machinery efficiency may also suffer due to poor tooth selection.

Consider the specific work conditions first. A tooth designed for clay might struggle in rocky environments. Observing wear patterns can reveal insights into performance. If a tooth breaks frequently, it may not be suited for the job. Sometimes, operators rush decisions, leading to inadequate choices.

Material quality is critical. Harder materials resist wear but may crack under high impact. Softer materials can wear down quickly but offer better shock absorption. Evaluate your operational needs carefully. Investing time in selection can prevent future headaches. Often, overlooked details can make a significant difference in performance.

Choosing the right bucket teeth requires understanding the materials used in their production. The durability of these teeth is greatly influenced by the type of materials selected. For instance, steel alloys provide strength and resistance to wear. However, not all steel is created equal. A report from the Construction Equipment Manufacturers Association indicates that increased nickel content can enhance toughness.

Another common material is tungsten carbide. This offers exceptional hardness and longevity. Bucket teeth made with tungsten carbide can last significantly longer, reducing replacement needs by up to 50%. However, they can be more brittle. This makes them subject to chipping under certain conditions. So, users must balance durability with the potential for breakage.

Often, users overlook the importance of the environment in which the machinery operates. The soil type and moisture levels can impact the performance of bucket teeth. For example, rocky or abrasive conditions require tougher materials. This is particularly noteworthy since 30% of machinery failures are directly related to improper tooth selection. Selecting the right material not only improves efficiency, but also minimizes costly downtimes. Recognizing these factors can significantly influence operational success.

Choosing the right bucket teeth for your machinery is crucial. The shape and size of these components greatly influence performance and durability. Different applications require different designs. For instance, excavation jobs may benefit from sharper teeth, while grading tasks often call for broader options.

Research from industry reports indicates that mismatched bucket teeth can lead to costly downtime. For example, using the wrong size can increase wear on both the teeth and the machinery. Here’s a tip: always measure the bucket’s specifications before selecting teeth. This can prevent unnecessary expenses and improve efficiency.

Another point to consider is soil type and working conditions. Harder materials require tougher teeth. Select teeth with reinforced designs if you are operating in rocky environments. Conversely, softer soils may allow for less durable options. Evaluate your application needs carefully. A mismatch here can result in reduced productivity and frequent replacements, which impacts project timelines. Take into account the specific challenges of each job site.

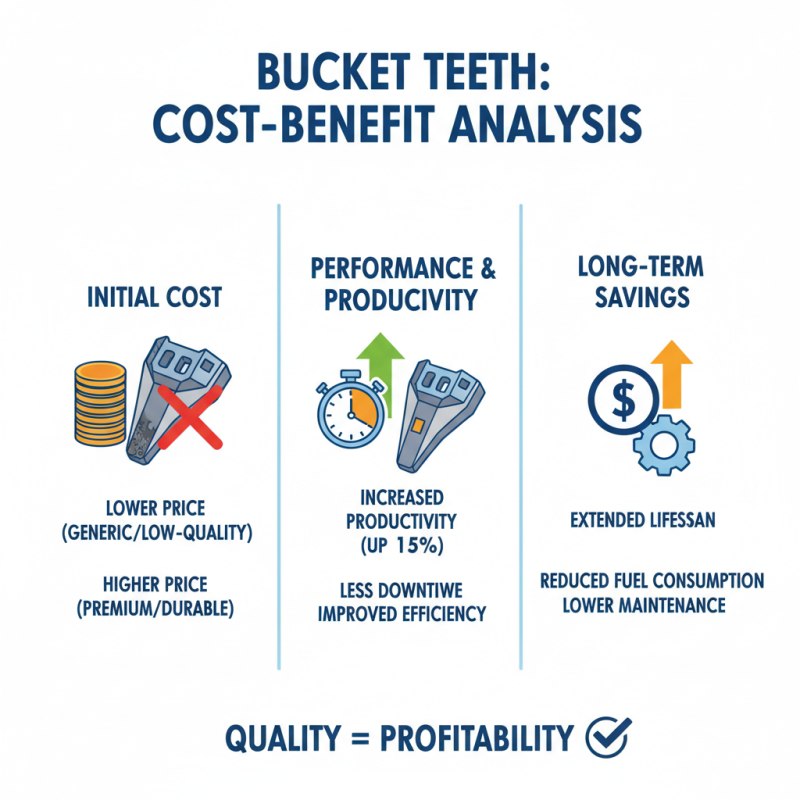

When selecting bucket teeth for machinery, analyzing the cost-benefit ratio is crucial. Quality bucket teeth can significantly impact performance. According to a recent industry report, using the right teeth can increase productivity by 15%. However, the initial investment for high-quality options can be steep.

Consider the long-term implications. Cheaper teeth may save money upfront but could lead to more replacements. Research indicates that low-cost options can wear out 30% faster than premium alternatives. This can offset any savings. On the other hand, investing in durable teeth can reduce maintenance costs over time.

It's essential to evaluate the workload. If machines are used in harsh conditions, premium teeth might be necessary. They often withstand more stress and reduce downtime. The data shows that replacing cheap teeth frequently can actually increase overall costs. Balancing investment with durability is key to making informed choices.

When selecting bucket teeth for your machinery, understanding industry standards is crucial. Different industries have varying requirements for strength and durability. Some regulations focus on the materials used in manufacturing these parts. Checking for certifications can provide confidence in quality. Look for evidence of testing and compliance with safety standards relevant to your industry.

Consider the performance expectations for your machinery. While a shiny finish might catch the eye, it does not always indicate superior performance. Sometimes, less visually appealing parts perform better in tough conditions. It’s wise to balance aesthetics with functionality. Seek advice from professionals who understand the specifics of your equipment.

Additionally, keep in mind that mistakes can happen during the selection process. An overlooked detail can lead to costly downtime. Test different options on-site, if possible. This allows you to assess how well they perform under your specific circumstances. Industry standards can guide you, but real-world application is where you’ll find true compatibility.

| Tip No. | Tip Description | Industry Standards | Certifications |

|---|---|---|---|

| 1 | Understand your machinery specifications | ISO 9001 | CE Marking |

| 2 | Evaluate the material types used | DIN 50049 | ISO 14001 |

| 3 | Check for compatibility with existing teeth | ANSI/ASAE | OSHA Compliance |

| 4 | Select the correct tooth shape for application | ISO 10816 | API Certification |

| 5 | Review wear resistance features | ASTM E8 | ISO 9000 |

| 6 | Assess the impact resistance of materials | ASTM A370 | SAE Standards |

| 7 | Check for proper installation guidelines | ISO 286 | Bureau Veritas |

| 8 | Consider vendor reliability and support | ISO 10002 | ISO 45001 |

| 9 | Examine warranty and return policies | ISO 13485 | TÜV Rheinland |

| 10 | Compare pricing and value for money | EN 10025 | ISO 50001 |