+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Replacing a Con Rod Bearing is crucial for any engine performance upgrade. This component connects the con rod to the crankshaft. A worn con rod bearing can lead to serious engine issues, such as knocking sounds or reduced power.

When replacing this bearing, precision matters. Many enthusiasts overlook the importance of proper torque specifications during installation. An incorrect fit can lead to early wear or failure. Observing the condition of the old bearing can offer insights. Are there unusual signs of wear? This reflects on overall engine health.

Don't rush this process. Taking the time to gather the right tools is essential. Cleanliness is just as vital. Dirt can damage new bearings, leading to regrets later. Thus, understanding the nuances of replacing a con rod bearing can be a game-changer for maintaining optimal engine performance.

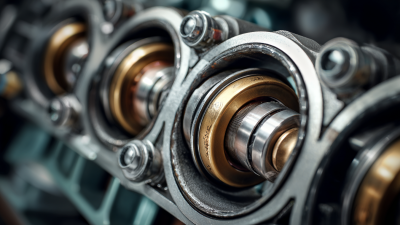

Connecting rod bearings play a crucial role in engine mechanics. They are located between the connecting rod and the crankshaft. These bearings help reduce friction during engine operation. Proper lubrication is essential for their performance. Without it, wear can lead to engine failure.

When replacing con rod bearings, pay attention to the clearances. Too tight can cause overheating. Too loose can lead to knocking sounds. Always check the bearing material too. Some may wear faster than others. Be mindful of the engine's oil flow, as it directly affects these components.

Tips: Always inspect the crankshaft for signs of damage. Clean all surfaces before installation. Use quality tools to avoid mistakes. If you feel uncertain, consult a professional. They can help you avoid costly errors. Mistakes are easy but can have lasting effects on engine health.

This chart demonstrates the performance index of an engine before and after the replacement of connecting rod bearings. A significant improvement can be observed post-replacement, indicating optimal engine performance.

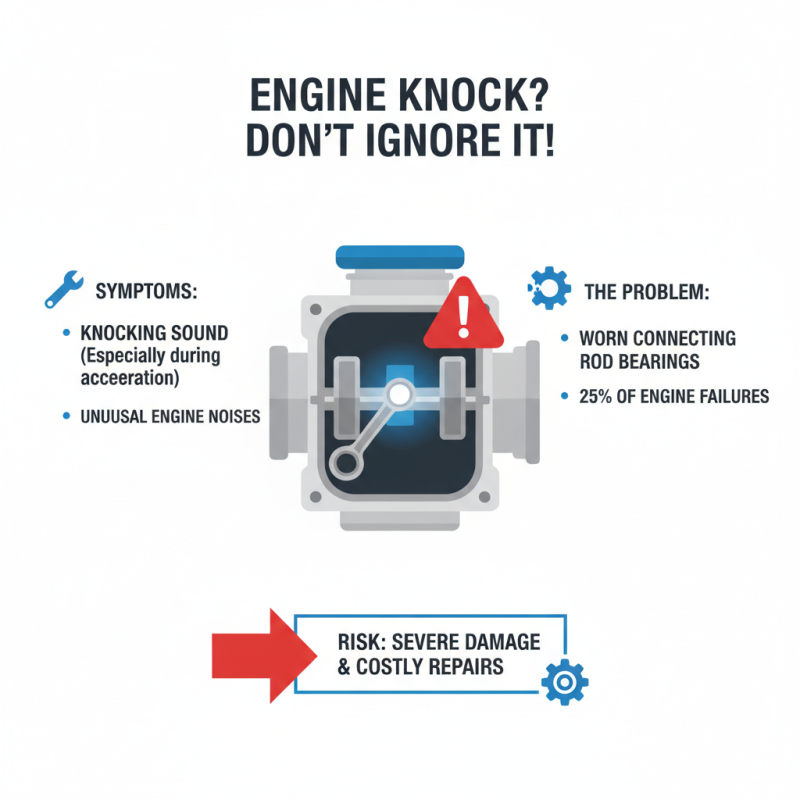

When experiencing unusual engine noises, it may signal a problem with the connecting rod bearings. A knocking sound, especially during acceleration, can indicate that the bearings are worn. According to industry reports, about 25% of engine failures are related to bearing issues. Ignoring these symptoms can lead to severe engine damage and costly repairs.

Excessive oil consumption is another sign that indicates the need for replacement. Worn bearings may cause oil to leak from the engine. A study published by a leading automotive research group noted that engines with deteriorating bearings often consume 30% more oil than normal. Additionally, fluctuations in oil pressure may be noticeable on your gauge. Consistently low pressure readings can result in decreased lubrication and increased wear.

Monitoring engine performance is crucial. If you notice a drop in power when accelerating, this can also hint at a connecting rod issue. Engine vibration can feel more pronounced as well. These signs should not be taken lightly. Recognizing them early may prevent bigger, more expensive problems down the road. Regular maintenance checks can be invaluable in identifying these warning signs before they escalate into major failures.

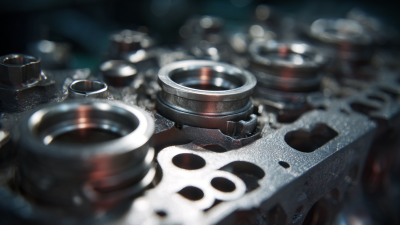

Replacing connecting rod bearings is crucial for optimal engine performance. To start, ensure the engine is cool and the vehicle is securely lifted. Use a socket wrench to detach the connecting rods from the crankshaft. Be cautious during this process; if bolts are over-torqued, they may strip or break.

Next, examine the old bearings for wear signs. Check for scoring or unusual friction marks. According to industry reports, 40% of engine failures can be traced back to worn bearings. When removing the old bearings, handle them carefully to avoid scratching the surfaces.

Install the new bearings with care, aligning them correctly. Many technicians overlook alignment, which can lead to premature failure. Ensure that the surface is clean before applying assembly lube. Proper lubrication is essential; a well-lubricated bearing can enhance engine efficiency by up to 15%. Regular checks and maintenance are vital. Neglecting these can result in costly repairs down the line. Pay attention to every detail in this process for best results.

Replacing connecting rod bearings is a critical task for enhancing engine performance. Proper installation is key to ensuring longevity and efficiency. Before starting, ensure all tools are ready. This includes the correct torque wrench and gasket sealant. Clean all surfaces meticulously. Any debris left behind can lead to premature failure.

When installing new bearings, align them properly. Misalignment can cause significant damage. Use a light film of engine oil to lubricate the bearings. This reduces friction during initial startup. Secure the bearings in place. It’s essential to avoid over-torquing the bolts. This can warp the connecting rod and lead to issues later.

Check the crankshaft journals for wear. In some cases, you may find unexpected damage. If there’s any doubt, measuring tools can help assess the tolerances accurately. After installation, double-check the work. Even minor mistakes can cost a lot over time. Take a moment to reflect on the process. What could be improved next time? This thought will enhance your skills progressively.

Replacing con rod bearings is crucial for maintaining engine health. When you do it, focus on best practices. Data shows that improper installation can lead to rapid wear. Engine failure often occurs due to overlooked details. This reinforces the need for precision during replacement.

When replacing bearings, cleanliness is vital. Debris can cause premature engine wear. Use lint-free towels and clean each part thoroughly before assembly. Ensure that surfaces are free of any old lubricant. This simple act can enhance engine longevity.

Tip: Always check rod alignment after installation. Misalignment can cause severe issues over time. Regularly monitor oil pressure. A drop in pressure might indicate bearing problems. Keeping records of your service can help identify patterns in engine performance. Consider these strategies to ensure a long-lasting engine.

| Step | Description | Best Practices | Expected Outcome |

|---|---|---|---|

| 1 | Prepare the Workspace | Keep the area clean and organized. | Easier access to tools and parts. |

| 2 | Remove the Engine Components | Disconnect battery and remove necessary parts. | Safeguard against accidental damage. |

| 3 | Access the Con Rod Bearings | Carefully remove the con rod cap. | Prevents wear on surrounding components. |

| 4 | Inspect the Old Bearings | Look for signs of wear or damage. | Determines need for other repairs. |

| 5 | Install New Bearings | Make sure to lubricate before installation. | Ensures proper function and reduces friction. |

| 6 | Reassemble Engine Components | Follow reverse order of disassembly. | Restores engine to working condition. |

| 7 | Test the Engine | Start the engine and listen for unusual noises. | Ensures successful installation and operation. |