+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

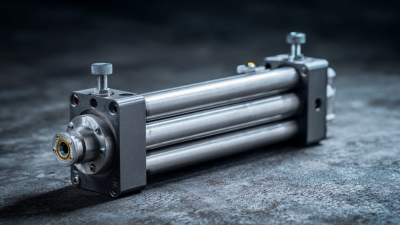

The evolution of arm cylinders has marked a significant breakthrough in modern engineering, bridging the gap between mechanical efficiency and innovative design. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $16.3 billion by 2025, driven largely by advancements in industries such as construction and manufacturing where arm cylinders play a pivotal role. These versatile components are integral to a wide range of applications, from robotic arms in automated assembly lines to hydraulic excavators that enhance productivity. The increasing demand for precision and reliability in engineering systems necessitates a thorough exploration of arm cylinders, their mechanics, and their diverse applications. As industries continue to evolve, understanding the innovations surrounding arm cylinders will be essential for engineers aiming to optimize performance and drive technological advancements.

The functionality of arm cylinders is rooted in fundamental engineering principles, primarily governed by the laws of mechanics and fluid dynamics. These hydraulic systems convert fluid power into mechanical force, allowing for precise movement and control in various applications. Understanding the dynamics of pressure, force, and motion is essential for engineers designing more effective and innovative arm cylinders. This includes considering factors such as load capacity, stroke length, and response time, all of which influence the overall performance of the system.

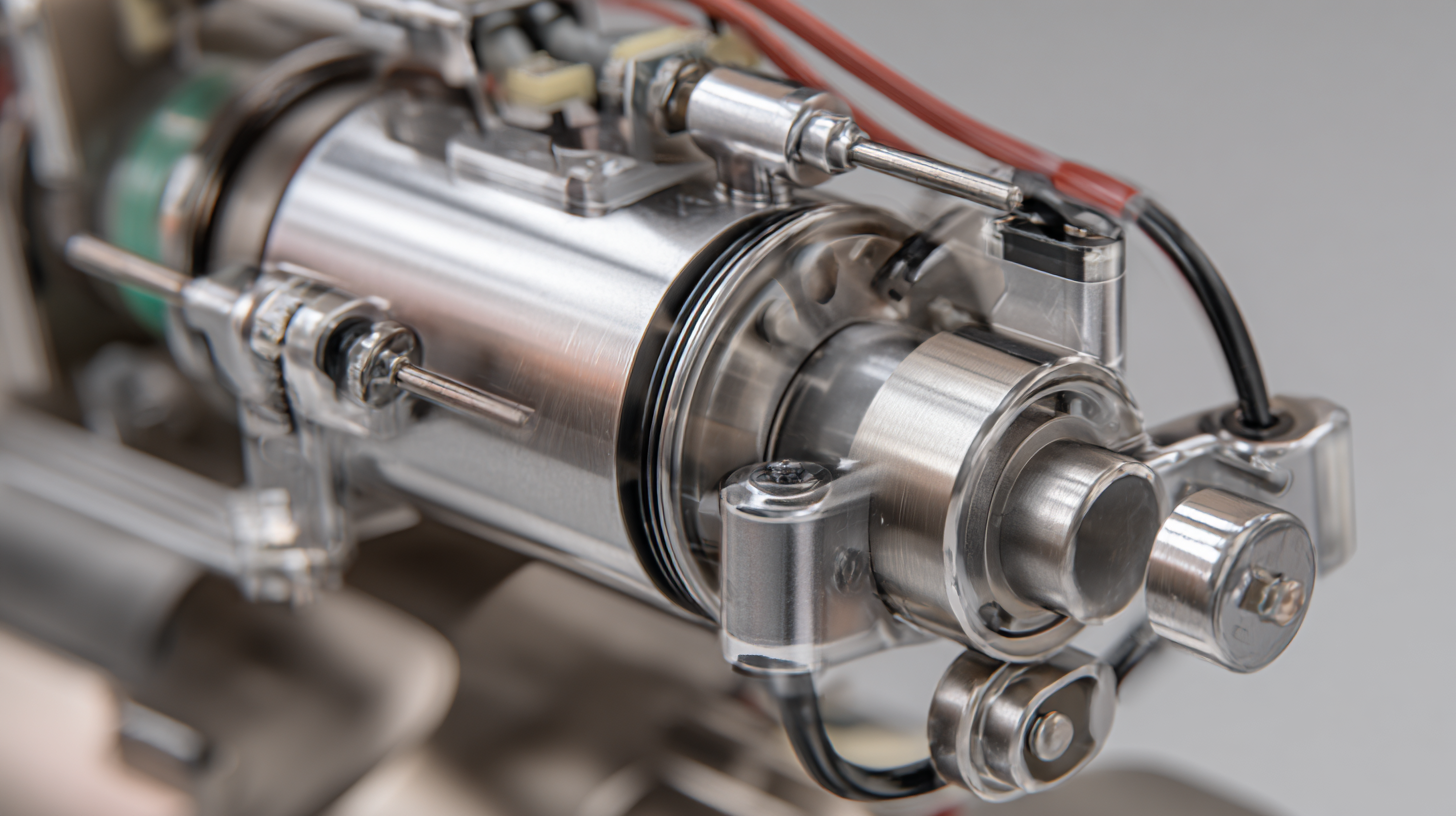

Innovations in arm cylinder technology have led to remarkable applications across industries, from robotics to automotive design. For instance, the educational model engine, resembling a miniaturized version of larger engines, exemplifies how complex mechanics can be simplified for learning purposes. By offering a kit that comprises numerous parts, it enables hands-on exploration of engine principles, mirroring the way engineers dissect and comprehend the workings of arm cylinders. This interplay between theory and practice illuminates the path toward future advancements in engineering, emphasizing the critical importance of mastering core functionalities within mechanical systems.

In recent years, the design and engineering of arm cylinders have undergone significant innovations, driven by advancements in materials science and computational modeling. According to a report by the International Federation of Robotics, the global robotics market is projected to reach $210 billion by 2025, with hydraulic and pneumatic cylinders playing a crucial role in enhancing robotic versatility and efficiency. Innovations such as lightweight composite materials and high-efficiency seals have improved the performance of arm cylinders, allowing them to handle higher loads with greater precision and reduced energy consumption.

Furthermore, smart technology integration is reshaping the arm cylinder landscape. The incorporation of sensors and IoT connectivity enables real-time monitoring and predictive maintenance, significantly reducing downtime. A study from the American Society of Mechanical Engineers highlights that companies adopting smart cylinder technologies report a 20% increase in operational efficiency. As these innovations continue to evolve, the potential applications for arm cylinders are expanding across industries, from manufacturing automation to medical robotics, demonstrating their pivotal role in modern engineering solutions.

This chart represents the advancements in various aspects of arm cylinder technology over the past decade. The data reflects the percentage improvements in efficiency, weight reduction, and operational lifespan due to recent innovations.

Arm cylinders, crucial components in modern engineering, find extensive applications across diverse industries. In manufacturing, these cylinders are integral to automation and robotics, enabling precise movement and control of machinery. For instance, in automotive assembly lines, arm cylinders facilitate the assembly process by delivering automated handling solutions, significantly improving efficiency and reducing lead times. The ability of these cylinders to exert substantial force while maintaining accuracy makes them indispensable in high-paced production environments.

In the construction industry, arm cylinders play a vital role in equipment such as excavators and cranes, providing the necessary power for lifting and moving heavy materials. Their robust design allows for reliable performance in demanding conditions, contributing to the safety and productivity of construction projects. Furthermore, in the aerospace sector, arm cylinders are utilized in aircraft maintenance and assembly, as they support critical operations requiring precision and reliability. The innovation in arm cylinder technology continues to drive advancements in these sectors, reinforcing their importance in an increasingly automated and efficient industrial landscape.

The manufacturing of arm cylinders presents a unique set of challenges that engineers must navigate to ensure optimal functionality and efficiency. According to a recent report by MarketsandMarkets, the demand for hydraulic actuators, which includes arm cylinders, is expected to grow by 4.5% annually, driven by the increasing need for automation in various sectors such as construction and manufacturing. However, manufacturers often face difficulties related to precision machining and material selection, which can lead to compromised performance and shortened lifespans of these critical components.

The manufacturing of arm cylinders presents a unique set of challenges that engineers must navigate to ensure optimal functionality and efficiency. According to a recent report by MarketsandMarkets, the demand for hydraulic actuators, which includes arm cylinders, is expected to grow by 4.5% annually, driven by the increasing need for automation in various sectors such as construction and manufacturing. However, manufacturers often face difficulties related to precision machining and material selection, which can lead to compromised performance and shortened lifespans of these critical components.

To tackle these challenges, innovations in materials and production processes are critical. Advanced composites and specialized surface treatments have emerged as viable solutions to enhance durability and resistance to environmental factors. A study published in the Journal of Manufacturing Science and Engineering highlights that the use of high-strength aluminum alloys can significantly reduce weight while maintaining structural integrity, making arm cylinders more efficient. Implementing lean manufacturing techniques also helps in minimizing waste and improving production timelines.

Tip: Consider investing in advanced simulation software that can optimize the design process for arm cylinders. This not only streamlines production but also enhances performance through predictive analytics. Furthermore, fostering close collaborations with material suppliers can ensure access to the latest technological advancements, which is vital for overcoming manufacturing challenges.

The future of arm cylinder technology is poised for significant advancements, particularly as the global hydraulics market is projected to expand from an estimated $39.40 billion in 2025 to approximately $44.26 billion by 2030. This growth underscores the increasing demand for hydraulic systems across various applications, from industrial machinery to robotics. Innovations in arm cylinder design are likely to focus on improving efficiency, precision, and adaptability, thereby enhancing their functionality in modern engineering projects.

As we look ahead, trends in cylinder deactivation systems are also gaining traction, particularly with technologies such as hydraulic lifter deactivation systems and rocker-arm locking mechanisms. These developments hint at a future where arm cylinders are not only more versatile but also able to operate with reduced energy consumption and optimized performance. With the integration of advanced materials and smart technologies, arm cylinders are expected to evolve, enabling engineers to tackle increasingly complex challenges in automation and machinery design.