+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the competitive landscape of engine performance, selecting the right cylinder liner is paramount for optimizing efficiency and durability. Cylinder liners, acting as protective barriers between the internal combustion process and the engine block, play a crucial role in enhancing engine life.

According to a report by Frost & Sullivan, the global automotive cylinder liner market is projected to reach $2.1 billion by 2025, driven largely by the increasing demand for high-performance engines in both passenger and commercial vehicles.

The choice of cylinder liner material, design, and manufacturing quality can significantly influence an engine's thermal efficiency, wear resistance, and overall performance. Industry analyses indicate that engines utilizing advanced cylinder liner technologies can achieve fuel efficiency improvements of up to 15%, while also reducing emissions and operational costs. As manufacturers strive to meet stringent environmental regulations, understanding the intricacies of cylinder liners becomes essential for those looking to maximize engine performance and compliance.

This essential guide will delve into the key considerations for selecting the optimal cylinder liner, addressing factors such as material science advancements, compatibility with engine designs, and the implications of these choices on long-term performance. By leveraging current research and insights from industry experts, engine builders can make informed decisions that enhance both performance and reliability.

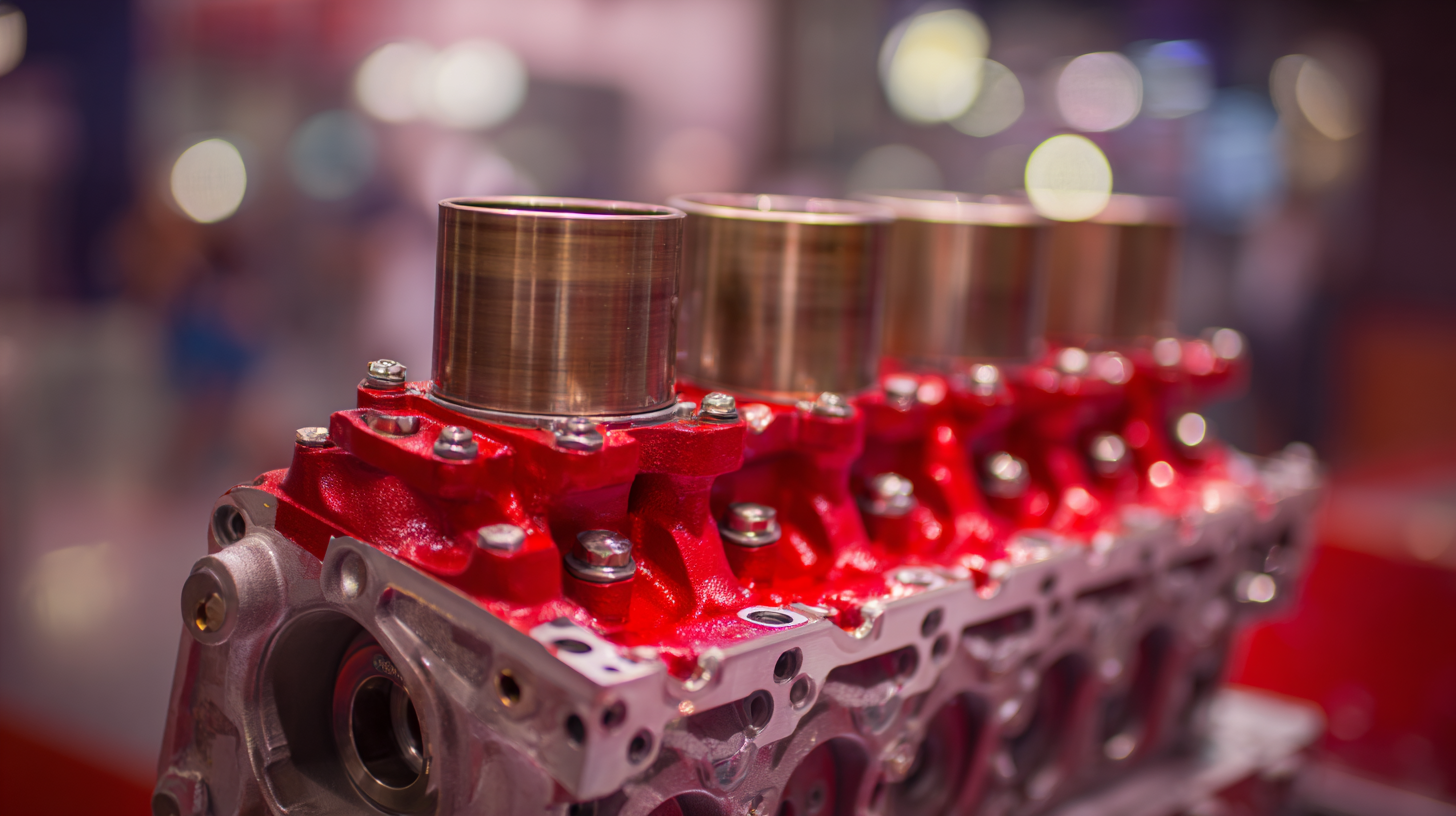

Cylinder liners play a crucial role in maximizing engine performance by providing a controlled environment for the combustion process. As the surface that directly interacts with the combustion chamber, cylinder liners are responsible for maintaining optimal temperature and pressure conditions. Their material composition and design can significantly influence heat transfer, wear resistance, and overall engine efficiency. High-quality liners can enhance the sealing between the piston and the cylinder, reducing blow-by gases and improving compression, which is essential for generating power.

The choice of cylinder liner also impacts the engine's longevity and maintenance needs. Different engine applications require specific liner properties to withstand varying loads and thermal stresses. For instance, heavy-duty engines often utilize thicker, cast-iron liners for enhanced durability, while high-performance engines might employ aluminum liners for weight reduction and improved heat dissipation. Understanding these factors allows engineers to select liners that complement the intended use of the engine, ultimately pushing performance boundaries further while ensuring reliability.

When selecting the appropriate cylinder liner for maximizing engine performance, understanding the types of materials and design considerations is critical. Cylinder liners are typically made from cast iron, aluminum, or composite materials. According to a report by the International Journal of Engine Research, cast iron remains a popular choice due to its excellent wear resistance and cost-effectiveness, making it ideal for high-volume manufacturing. However, aluminum liners are gaining traction, particularly in high-performance applications, due to their lightweight nature and superior thermal conductivity. This trend is corroborated by data from the Engine Manufacturers Association, which indicates a growing preference for aluminum in modern engines to improve fuel efficiency and reduce emissions.

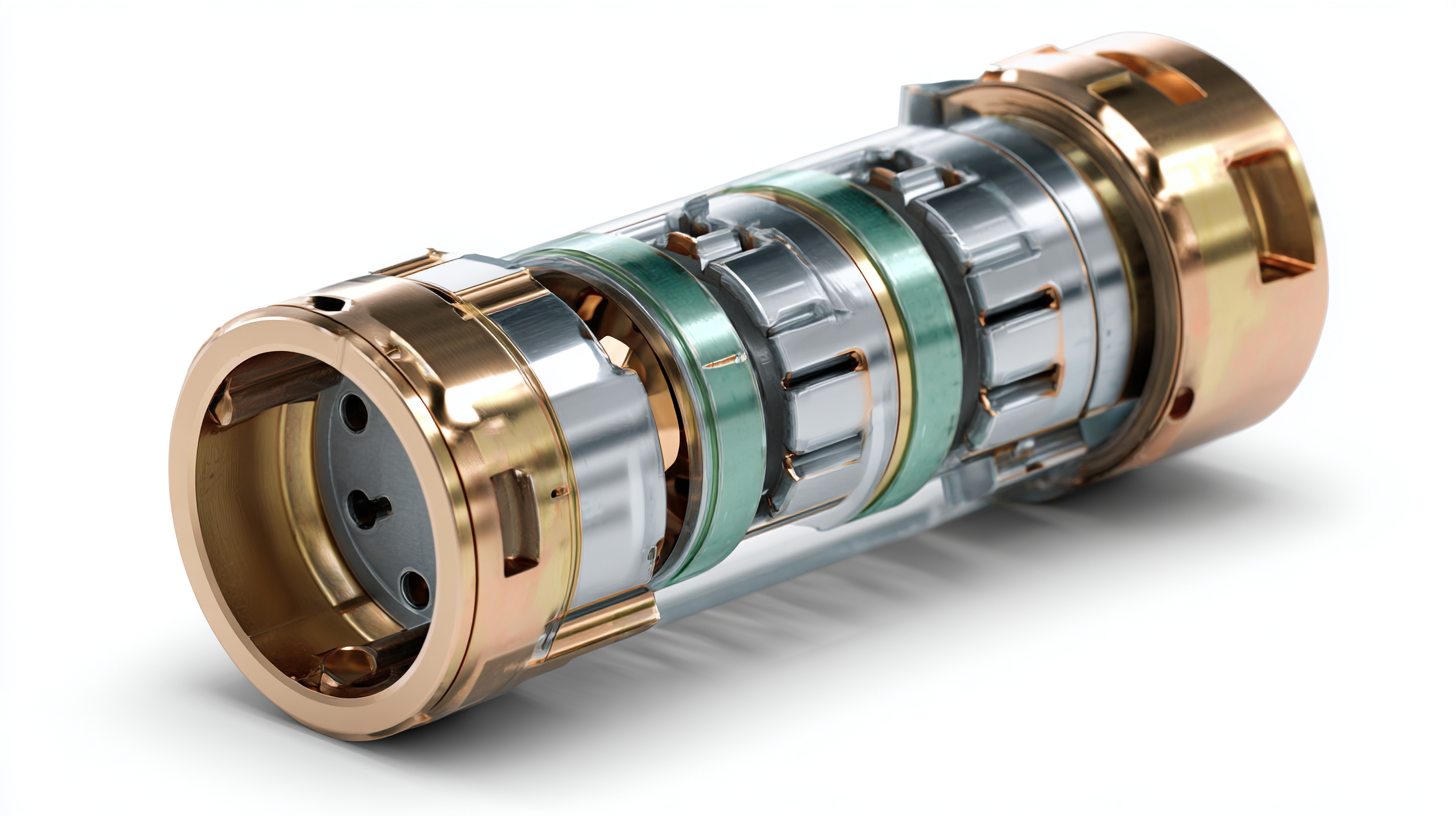

Design considerations also play a vital role in cylinder liner performance. The wall thickness, surface finish, and coating technologies can substantially affect the overall functionality of the liner. A study published in the Journal of Automobile Engineering highlights that optimizing the wall thickness can lead to a 5-7% improvement in thermal efficiency, particularly in turbocharged engines. Moreover, advanced coatings, such as plasma-sprayed ceramic, can enhance durability and reduce friction, resulting in extended service life. These considerations reflect the industry's shift toward innovative designs that not only enhance engine performance but also address environmental regulations.

When selecting a cylinder liner for a specific engine, several critical factors must be considered to maximize performance and longevity. One of the primary influences is the engine’s operating environment, which can vary significantly based on application—whether it's in heavy-duty vehicles, industrial equipment, or high-performance sports cars. Endurance in extreme temperatures and pressures may dictate the choice of materials used in the liner, such as cast iron or advanced composite options, ensuring optimal thermal efficiency and wear resistance.

Another essential consideration is the engine’s design and intended function. Factors such as bore size, stroke length, and engine configuration directly impact the liner's dimensions and specifications. Additionally, the choice between a dry or wet liner system plays a vital role in cooling efficiency and maintenance needs. Manufacturers often provide detailed guidelines to match cylinder liners to specific engine models, emphasizing the importance of compatibility to avoid performance issues and enhance reliability throughout the engine's lifecycle. Making informed decisions based on these factors is crucial for achieving the desired engine performance.

When it comes to maximizing engine performance, the cylinder liner plays a crucial role in both longevity and efficiency. Proper maintenance is key to ensuring that these essential components withstand the rigors of operation. One of the most important maintenance tips is to ensure the proper installation of cylinder sleeves. Collaborating with sleeve manufacturers can help engine builders achieve optimal fit and function, which can significantly enhance the lifespan of the cylinder liners.

Additionally, investing in high-quality coolants can protect engines from overheating and prevent damage caused by corrosion and sediment build-up in the cooling system. Regularly monitoring coolant levels and conditions can prevent potential issues before they escalate.

Lastly, applying specialized coatings to engine parts can improve performance and durability. These coatings help reduce friction and wear, allowing the engine to operate more smoothly and efficiently. By implementing these maintenance tips, engine builders can effectively enhance the longevity and efficiency of cylinder liners, ensuring reliable engine performance for years to come.

When it comes to optimizing engine performance, the choice between aftermarket and OEM cylinder liners is critical. OEM cylinder liners are designed specifically for each engine model, ensuring a perfect fit and compatibility. However, they often come with a higher price tag. According to industry reports, up to 90% of OEM parts are manufactured to stringent standards that can enhance engine longevity and efficiency. For example, OEM liners typically offer superior material properties, such as enhanced corrosion resistance and durability, which can be crucial for maintaining performance over time.

On the other hand, aftermarket cylinder liners, while more affordable, can vary significantly in quality. Some aftermarket options use less expensive materials or manufacturing processes that can compromise engine performance. Research shows that using low-quality liners can lead to premature wear, affecting overall engine health. Nevertheless, reputable aftermarket brands have emerged, providing products that often meet or exceed OEM specifications, offering a compelling alternative for budget-conscious enthusiasts. Ultimately, the decision hinges on balancing cost with the desired performance and longevity for your engine.

| Criteria | Aftermarket Cylinder Liners | OEM Cylinder Liners |

|---|---|---|

| Cost | Generally lower | Typically higher |

| Quality Assurance | Varies by manufacturer | Consistent quality |

| Fit | May require adjustments | Perfect fit |

| Warranty | Limited or no warranty | Comprehensive warranty |

| Performance | Inconsistent across products | Proven performance |

| Availability | Widely available | May require special order |