+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

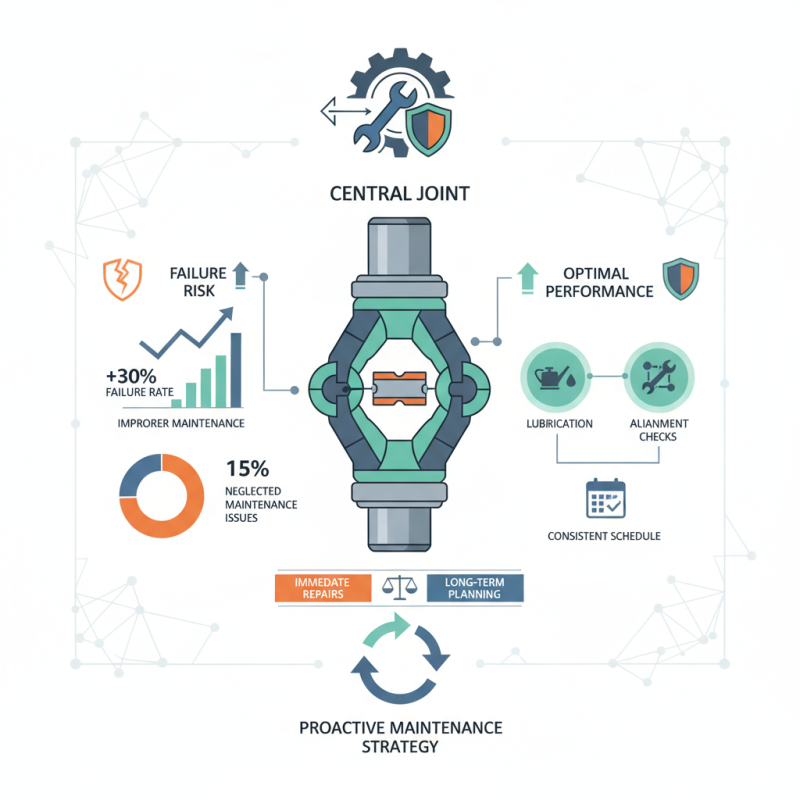

Maintaining and repairing a center joint is essential for optimal performance. The center joint plays a crucial role in various industries, particularly in automotive and structural applications. According to industry reports, improper maintenance can lead to a 30% increase in failure rates. This highlights the need for regular inspections and repairs.

Regular wear and tear can compromise the effectiveness of the center joint. Over time, factors such as temperature fluctuations and environmental conditions can impact its integrity. A surprising statistic shows that 15% of center joint issues arise from neglected maintenance practices. Many professionals overlook this aspect, leading to costly downtimes.

Addressing center joint maintenance requires a practical approach. Simple actions like lubrication and alignment checks can significantly prolong the joint’s life. However, the challenge lies in creating a consistent maintenance schedule. Many teams struggle to find the right balance between immediate repairs and long-term planning. These issues call for reflection and a strategic focus on proactive maintenance.

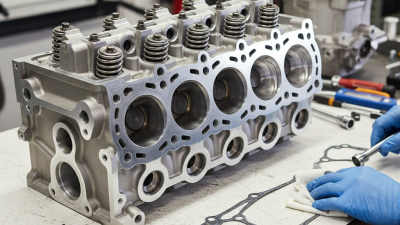

The center joint in vehicles plays a pivotal role in ensuring smooth motion and stability. This crucial component connects the driveshaft to the wheel assembly, allowing for movement during steering or suspension travel. When functioning well, it contributes to overall vehicle handling and comfort. A malfunction can lead to vibrations, noise, and steering issues.

Regular maintenance is essential for the longevity of the center joint. Inspect it periodically for wear and tear. Look for signs of grease leaks or corrosion. A worn center joint can compromise safety. If you notice any unusual sounds while turning, it may indicate a problem. Don't ignore these warnings.

Tips: Keep an eye on steering responsiveness. If it feels loose or unresponsive, check the center joint. It's better to fix issues early than face costly repairs later. Also, consider lubricating the joint during routine servicing. Proper lubrication can prevent premature wear. Always prioritize safety and vehicle performance.

A failing center joint can lead to various noticeable symptoms. One common sign is a creaking noise while driving. This sound often indicates a lack of lubrication or wear and tear in the joint. You might also feel vibrations from the steering wheel, which can indicate a serious issue. These vibrations usually become more pronounced when turning.

Another symptom is uneven tire wear. If the center joint is not functioning properly, it affects alignment. This misalignment leads to tires wearing out quicker on one side. If you frequently need to realign your wheels, the center joint might be the culprit. Additionally, difficulty in steering can also signal a problem. It can feel heavy or unresponsive, which is frustrating while driving.

Ignoring these symptoms can lead to more severe issues. Your vehicle's handling may deteriorate, impacting safety. The cost of repairs will rise if the problem is not addressed promptly. Regular inspections can help catch these signs early. Awareness and timely action can save you from bigger headaches down the road.

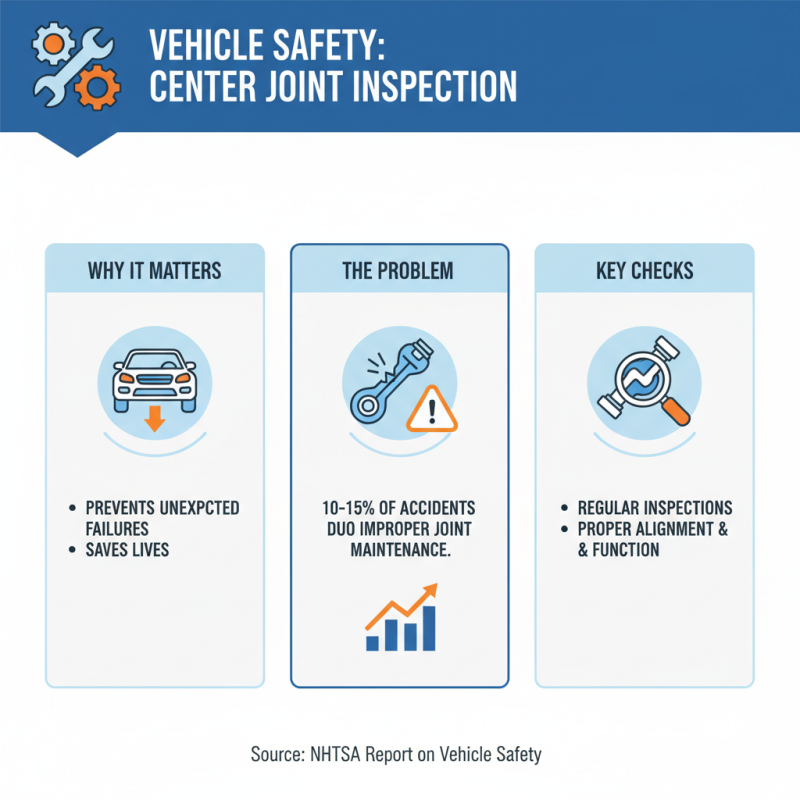

Inspecting a center joint is crucial for vehicle safety. Regular checks can prevent unexpected failures. A report from the National Highway Traffic Safety Administration indicates that improper joint maintenance contributes to 10-15% of vehicle-related accidents. Ensuring proper alignment and function can save lives.

Begin by visually inspecting the joint for cracks or wear. Use a flashlight to check for subtle damage. Pay attention to the area around the joint; grease leakage can indicate issues. The lifespan of a center joint varies but typically lasts between 70,000 and 100,000 miles. Regular inspections can help identify problems early.

Listen for unusual noises during operation. Clunking sounds might suggest a failing joint. If you notice vibrations, it’s worth taking a closer look. The delicate nature of these components means that neglect can lead to significant challenges. A thorough inspection can uncover hidden issues, which may require immediate attention and repairs.

Maintaining the center joint is essential for ensuring optimal performance. Regular visuals inspections can help identify potential issues early. Look for signs of wear or looseness. According to industry reports, about 40% of mechanical failures are attributed to poor maintenance practices. It's crucial to address these problems proactively.

Lubrication plays a vital role in the health of the center joint. Use appropriate lubricants to reduce friction. Studies suggest that proper lubrication can extend component life by up to 50%. Nevertheless, many fail to apply adequate lubrication regularly. It’s easy to overlook this simple task, yet it has a significant impact.

Cleaning the center joint area is equally important. Accumulated dirt can lead to corrosion and wear. A clean workspace encourages better maintenance habits. Surprisingly, about 30% of maintenance issues arise from neglecting cleaning routines. Each of these elements requires continuous attention and effort. Recognizing imperfections in maintenance practices can lead to improved outcomes.

| Method | Description | Frequency | Notes |

|---|---|---|---|

| Visual Inspection | Check for visible signs of wear, corrosion, or damage. | Monthly | Address any visible issues immediately. |

| Lubrication | Apply appropriate grease to ensure smooth movement. | Every 3 months | Use recommended lubrication standards. |

| Tightening Bolts | Ensure all connection bolts are properly tightened. | Every 6 months | Check torque specifications. |

| Component Replacement | Replace any damaged or worn components. | As needed | Plan for regular checks to minimize downtime. |

| Alignment Check | Verify and adjust the alignment of the joint. | Annually | Misalignment can lead to premature wear. |

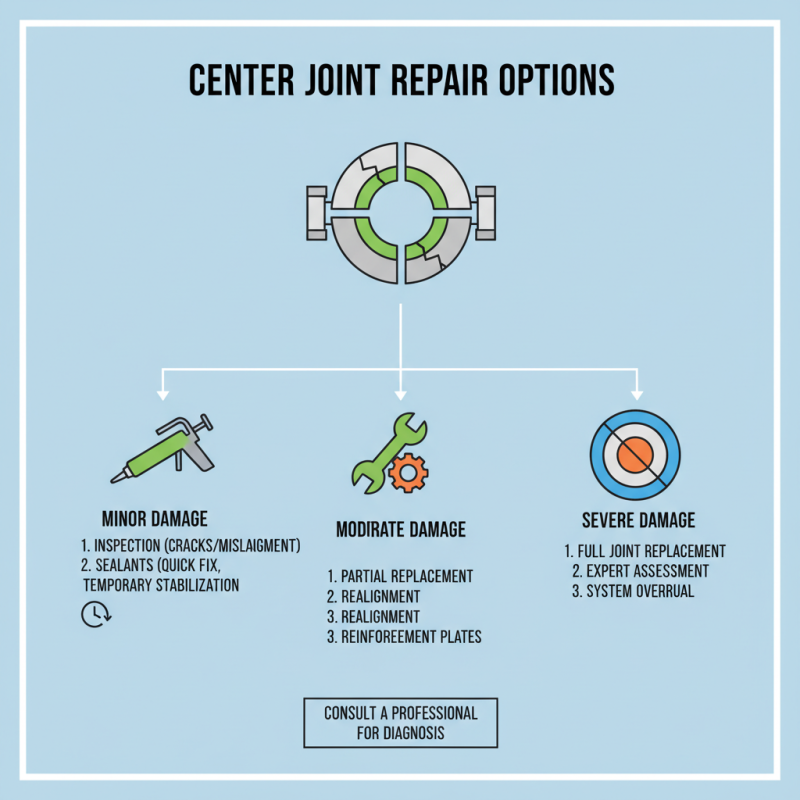

Maintaining and repairing a center joint can be daunting. When damage occurs, it's essential to recognize the options available. Depending on the severity, you may need to consider multiple approaches. A simple inspection can often reveal cracks or misalignments. If you notice small damages, sealants can offer a quick fix. They might not last long, but they can stabilize the joint temporarily.

For more significant issues, a full replacement might be necessary. This option can be costly, but it ensures a reliable, long-term solution. You should carefully measure the joint before purchasing a replacement. It's not uncommon to find discrepancies that can complicate things. If you're not sure about your skills, hiring a professional could save future headaches. In some cases, they might identify underlying problems you missed.

It's also essential to maintain the joint regularly. Cleaning it frequently can prevent further degradation. Sometimes, it may require lubrication to keep it functioning efficiently. Ignoring these steps can lead to more severe repairs down the line. The path to repair is rarely perfect, with learning curves along the way. Adjusting your approach each time can lead to better results in the long run.