+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

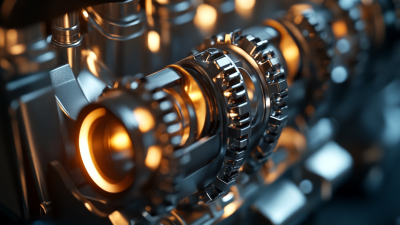

In the ever-evolving landscape of modern engine technology, the performance of the Fuel Control Valve is crucial for optimal engine efficiency and emissions reduction. According to a recent report by the International Energy Agency, advancements in fuel management systems could lead to a potential reduction of up to 30% in fuel consumption in the transportation sector. These statistics underscore the pressing need for innovative solutions in the design and operation of Fuel Control Valves, which play a pivotal role in regulating fuel flow and maintaining engine performance under varying operational conditions. As manufacturers strive to meet stringent environmental regulations and consumer demands for improved fuel economy, embracing cutting-edge technologies and strategies for enhancing the performance of Fuel Control Valves has never been more essential. This blog will explore various innovative solutions aimed at optimizing Fuel Control Valve performance, contributing to more efficient and environmentally friendly engines in the years to come.

Fuel control valves play a crucial role in modern engines, and their functionality is often challenged by a variety of factors. One significant issue is the performance consistency affected by the intricacies of gasoline direct injection systems. According to recent observations, these systems can suffer from injector clogs and fuel atomization problems, leading to inefficiencies and performance dips. Addressing these design flaws is increasingly essential as manufacturers push for higher power outputs while maintaining emissions standards.

Moreover, as diesel technology evolves, fuel pump systems must also adapt to meet new demands. The diesel fuel pump market is projected to expand from $25.1 billion in 2022 to $28.2 billion by 2027, indicating a growing need for improved flow and pressure capabilities and enhanced durability. As manufacturers strive to optimize fuel control valve performance, overcoming the challenges posed by emission control and new fuel technologies will be vital for achieving the reliability and efficiency demanded in today’s automotive landscape. Integrating advanced materials and designs into fuel valve systems can significantly mitigate these issues, ensuring that modern engines deliver optimal performance while adhering to stringent regulations.

| Challenge | Impact on Performance | Innovative Solutions | Expected Benefits |

|---|---|---|---|

| Inconsistent Fuel Delivery | Unstable engine performance and decreased efficiency | Advanced sensors for real-time monitoring and feedback loops | Improved fuel efficiency and smoother operation |

| Wear and Tear of Components | Reduced longevity and reliability of the valve | Use of advanced materials and coatings | Extended lifespan and reduced maintenance costs |

| Temperature Sensitivity | Performance variations in different operating conditions | Thermal management systems integrated into the design | Consistent performance across a wide temperature range |

| Calibration Issues | Decreased accuracy and control over fuel mixing | Automated calibration systems with machine learning algorithms | Enhanced precision in fuel control and improved emissions |

The performance of fuel control valves is critically influenced by the quality of fuel used in modern engines. According to a report by the American Petroleum Institute (API), using high-quality fuel can improve engine efficiency by up to 10%. This enhancement is largely due to the reduced presence of impurities and better combustion characteristics, which directly affect the actuation and responsiveness of fuel control valves. Such valves rely on precise fuel delivery to optimize air-fuel mixtures for efficient combustion, meaning subpar fuel can lead to erratic valve performance and reduced engine power output.

Additionally, a study conducted by the Society of Automotive Engineers (SAE) highlights that lower-grade fuels often lead to higher rates of valve wear and fouling. Over time, this wear compromises the valve's ability to maintain optimal performance, potentially increasing fuel consumption and harmful emissions. The implications of using inferior fuel are significant: it not only increases operational costs through diminished efficiency but can also escalate maintenance requirements, impacting the overall longevity of the engine. Selecting the right fuel quality is thus indispensable for maximizing the performance of fuel control valves and enhancing engine efficiency.

The fuel control valve plays a crucial role in the efficiency and performance of modern engines. As we look ahead to 2033, the market for fuel control valves is projected to reach an impressive $1.5 billion, fostered by advancements in technology that enhance responsiveness. Innovative solutions, such as advanced sensors and actuators, are at the forefront of this transformation, offering precise control over fuel delivery in real-time. These technologies not only improve engine performance but also contribute to reduced emissions and increased fuel efficiency.

One of the most significant breakthroughs in fuel control valve technology is the integration of smart algorithms that optimize valve operation based on driving conditions. This intelligent approach enables the valves to respond dynamically, maintaining optimal fuel flow and enhancing engine responsiveness. As manufacturers continue to focus on developing innovative mechanisms, we are likely to see a surge in the adoption of these advanced fuel control systems. The anticipated steady compound annual growth rate of 8.4% through 2025 reflects the industry’s commitment to delivering superior fuel control solutions that meet modern environmental and performance standards.

Regular maintenance of fuel control valves is essential for ensuring optimal engine performance and longevity. One effective strategy is to implement a routine inspection schedule. This involves checking for signs of wear, such as corrosion or leakage, and replacing worn components before they lead to major malfunctions. Regularly cleaning the valve internals can also prevent buildup of contaminants that could hinder performance.

Regular maintenance of fuel control valves is essential for ensuring optimal engine performance and longevity. One effective strategy is to implement a routine inspection schedule. This involves checking for signs of wear, such as corrosion or leakage, and replacing worn components before they lead to major malfunctions. Regularly cleaning the valve internals can also prevent buildup of contaminants that could hinder performance.

Another important aspect of maintenance is monitoring the fuel quality. Contaminated fuel can cause deposits to form within the valve, obstructing flow and potentially damaging internal parts. Using high-quality fuel and installing fuel filters can significantly reduce the risk of these issues. Additionally, employing diagnostic tools to monitor valve performance can help identify irregularities early, allowing for timely corrective actions. By prioritizing these maintenance strategies, engine operators can enhance the reliability and efficiency of fuel control valves, ultimately contributing to improved overall engine function.

As the automotive industry pushes toward greater efficiency and sustainability, the design and optimization of fuel control valves become increasingly critical. According to a report by MarketsandMarkets, the global automotive fuel delivery systems market is expected to grow from $21.5 billion in 2020 to $29.8 billion by 2025, with fuel control valves playing a vital role in this trend. Innovations such as electronically controlled fuel injection systems and variable valve timing are driving the evolution of these components, as manufacturers seek to enhance engine performance and reduce emissions.

Future trends in fuel control valve design center on the integration of advanced materials and smart technologies. Research indicates that the use of lightweight and durable materials can improve the responsiveness and longevity of fuel control valves, ultimately contributing to more efficient fuel consumption. Furthermore, the advent of Internet of Things (IoT) technology allows for real-time monitoring and data collection, enabling predictive maintenance and adaptive performance tuning. This shift towards intelligent fuel control systems is set to redefine engine optimization strategies, meeting the demands of increasingly stringent emissions regulations and consumer expectations for greener vehicles.