+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

The Common Rail system has revolutionized the landscape of modern diesel engines, serving as a pivotal technology in improving performance and efficiency. As per the latest reports from the Diesel Technology Forum, the adoption of Common Rail fuel injection systems has led to significant enhancements in engine power output, fuel efficiency, and reduced emissions. In fact, studies indicate that engines equipped with Common Rail systems can achieve up to 30% better fuel economy compared to traditional injection methods. By delivering fuel at high pressure to the injectors, Common Rail technology enables more precise control over the injection timing and quantity, resulting in smoother operation and lower levels of harmful pollutants. Consequently, understanding the mechanics and advantages of Common Rail systems is essential for industry stakeholders aiming to meet stringent emission regulations and improve overall engine performance in the increasingly competitive automotive market.

The Common Rail system has revolutionized the landscape of modern diesel engines, serving as a pivotal technology in improving performance and efficiency. As per the latest reports from the Diesel Technology Forum, the adoption of Common Rail fuel injection systems has led to significant enhancements in engine power output, fuel efficiency, and reduced emissions. In fact, studies indicate that engines equipped with Common Rail systems can achieve up to 30% better fuel economy compared to traditional injection methods. By delivering fuel at high pressure to the injectors, Common Rail technology enables more precise control over the injection timing and quantity, resulting in smoother operation and lower levels of harmful pollutants. Consequently, understanding the mechanics and advantages of Common Rail systems is essential for industry stakeholders aiming to meet stringent emission regulations and improve overall engine performance in the increasingly competitive automotive market.

The evolution of diesel engine technology has been significantly influenced by advancements in common rail systems. These systems enhance fuel injection precision and efficiency, which is critical as regulations tighten around emissions. In modern applications, including freight locomotives, the shift towards renewable diesel and high-pressure common rail systems has contributed to cleaner operations and reduced greenhouse gas emissions. This evolution demonstrates how integrating advanced fuel management technologies helps achieve compliance with stringent standards, such as Euro VI.

The evolution of diesel engine technology has been significantly influenced by advancements in common rail systems. These systems enhance fuel injection precision and efficiency, which is critical as regulations tighten around emissions. In modern applications, including freight locomotives, the shift towards renewable diesel and high-pressure common rail systems has contributed to cleaner operations and reduced greenhouse gas emissions. This evolution demonstrates how integrating advanced fuel management technologies helps achieve compliance with stringent standards, such as Euro VI.

Tips: When considering upgrades or maintenance for diesel engines, pay attention to the type of fuel injectors used—specifically, those that are compatible with common rail systems for optimal performance. Regularly consulting technical manuals and staying updated on the latest engine oil specifications can also aid in extending engine life and improving fuel economy.

The landscape of diesel machinery is transforming, as seen in the introduction of newer locomotives with enhanced capabilities. The focus on cleaner emissions not only drives technology advancements but also signifies a commitment to sustainability in the transportation sector. With the continuous development of low viscosity oils and fuel injection systems, the future of diesel engines appears promising while addressing environmental concerns.

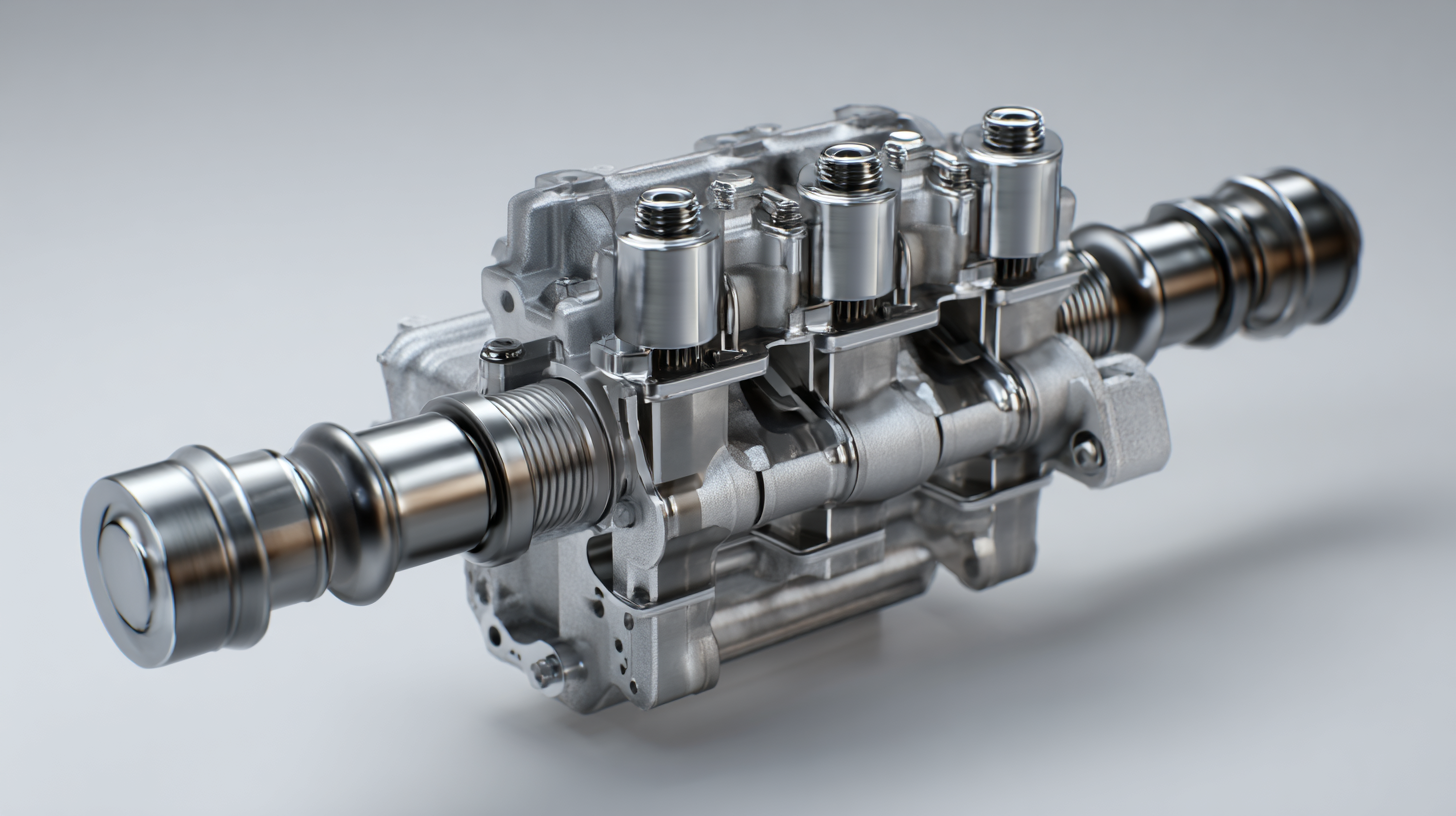

Common rail fuel injection systems have revolutionized modern diesel engine performance, offering several key benefits that enhance efficiency and power delivery. One of the primary advantages of a common rail system is its ability to deliver fuel at high pressure, allowing for precise control over injection timing and quantity. This precision results in more complete combustion, leading to reduced emissions and better fuel economy. The ability to inject multiple times during each combustion cycle further optimizes performance, minimizing noise and vibration typical of conventional diesel engines.

Additionally, common rail systems support the implementation of advanced technologies such as turbocharging and exhaust gas recirculation, which work in tandem to boost engine responsiveness and overall power output. By allowing for a wider range of operating conditions, these systems significantly improve torque and horsepower, making diesel engines more versatile for various applications. Overall, the common rail fuel injection system not only enhances the performance of modern diesel engines but also aligns with stringent environmental regulations, showcasing its critical role in today’s automotive advancements.

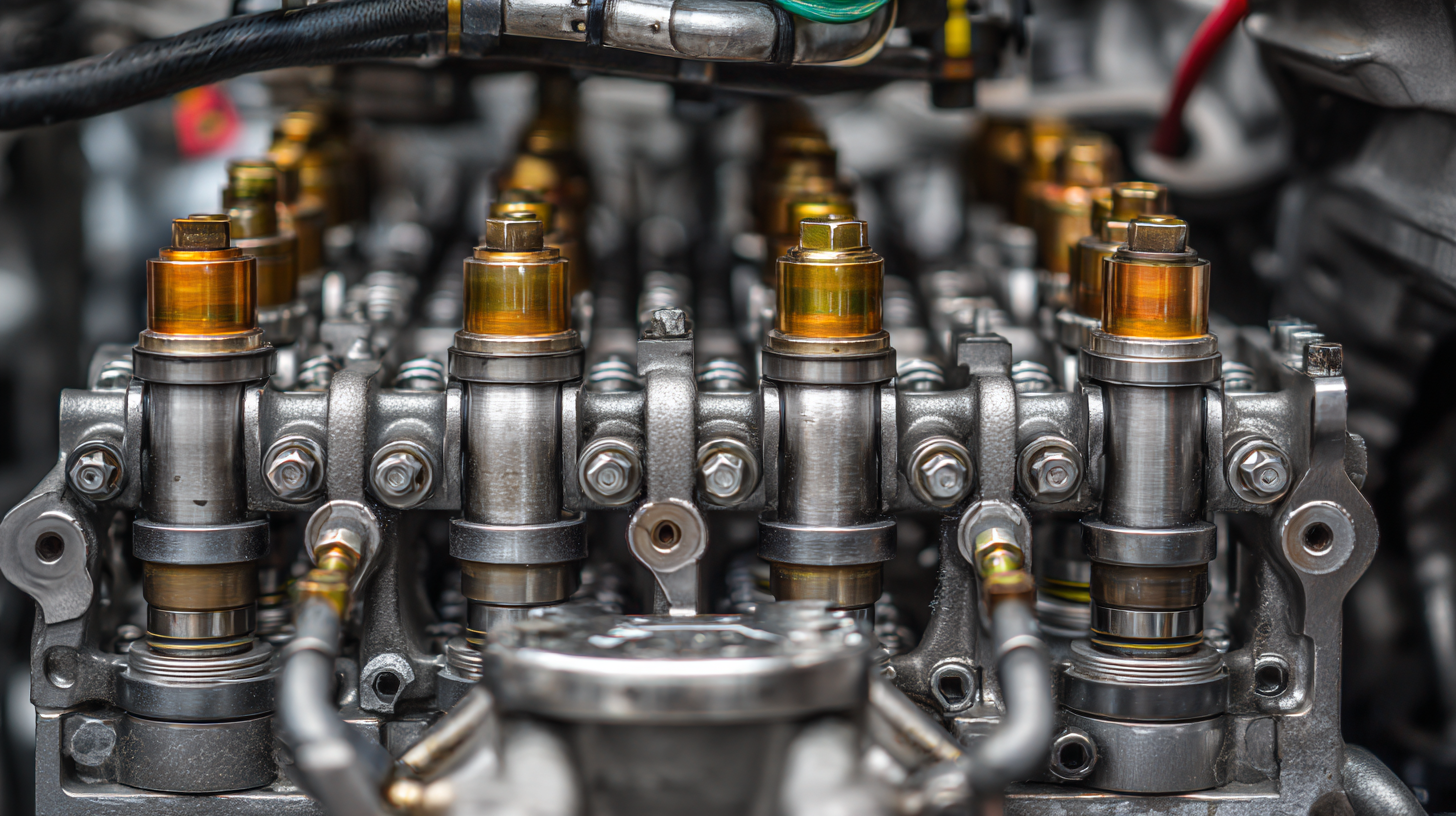

Common rail systems have revolutionized the performance of modern diesel engines, particularly in terms of emissions and fuel efficiency. This technology allows for multiple injections of fuel during a single combustion cycle, enabling a more precise control over the fuel delivery process. By optimizing the timing and volume of injections, common rail systems significantly enhance the combustion process, reducing harmful emissions like nitrogen oxides and particulate matter. This not only meets stringent environmental regulations but also addresses the growing demand for cleaner transportation solutions.

In addition to improving emissions, common rail systems contribute to better fuel efficiency. The high-pressure injection allows for finer fuel atomization, leading to more thorough combustion and reduced fuel consumption. As a result, these systems can provide a considerable boost in miles per gallon without sacrificing engine performance. The ability to adapt to various driving conditions further maximizes fuel economy, demonstrating the critical role common rail systems play in making diesel engines more sustainable and efficient in today’s automotive landscape.

The implementation of common rail technology in modern diesel engines presents several challenges that manufacturers must navigate to fully exploit its benefits. One significant challenge is the high-pressure fuel injection system design, which requires precise engineering and materials capable of withstanding extreme stresses. The fueling system must maintain consistent performance across a wide range of operational conditions, which can necessitate complex software and control algorithms to manage multiple injectors efficiently and achieve optimal combustion.

Additionally, the integration of common rail technology into existing diesel engines raises issues related to compatibility and retrofitting. Many older engine designs may not be easily adaptable to accommodate the sophisticated common rail system, leading to increased costs and extended downtime during the transition. Furthermore, there is a growing need to address environmental regulations, as modern diesel engines equipped with common rail technology must also comply with stringent emission standards. This creates an added layer of complexity, as engineers work to ensure that performance enhancements do not compromise compliance with environmental mandates.

| Dimension | Value |

|---|---|

| Fuel Injection Pressure Range | 1000 - 2000 bar |

| Common Rail Technology Adoption Rate | Over 70% |

| Advantages of Common Rail Systems | Reduced emissions, improved fuel efficiency, better performance |

| Key Challenges in Implementation | High costs, complexity of integration, maintenance issues |

| Expected Growth in Diesel Common Rail Systems | 5% CAGR by 2025 |

| Impact on NOx Emissions | Reduction by up to 30% |

The evolution of common rail systems (CRS) in diesel engines has marked a significant turning point in engine performance and efficiency. As industries push towards stringent emissions regulations, advancements in CRS technology have become crucial. According to a report by Frost & Sullivan, the global common rail fuel injection market is projected to reach $5.7 billion by 2025, driven by the increasing demand for fuel-efficient vehicles and the growing implementation of clean fuel technologies. This growth signals a robust future for innovations in CRS, focusing on enhancing combustion efficiency and minimizing emissions.

Future trends in common rail systems will likely emphasize high-pressure injection systems and adaptive strategies that optimize fuel delivery dynamically. Research indicates that next-gen CR systems will incorporate AI and machine learning capabilities to optimize injection timing and quantity, providing a more efficient combustion process. Additionally, developments in fuel injection technology, such as the use of alternative fuels, are anticipated to play a pivotal role in advancing the viability of diesel engines in a rapidly evolving automotive landscape. As OEMs and technology providers collaborate in R&D, we can expect to see breakthrough improvements that not only enhance engine performance but also align with global sustainability goals.