+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

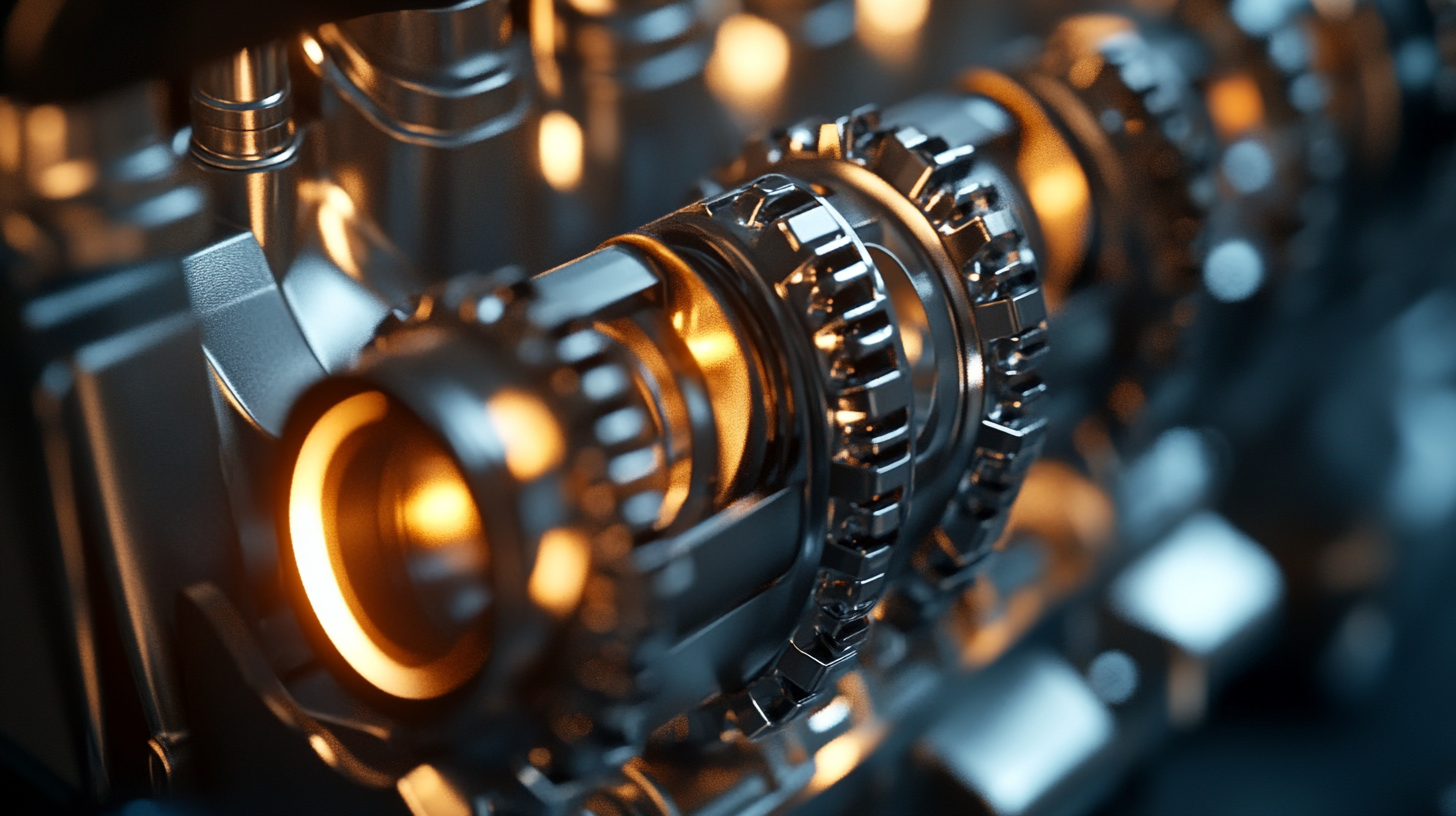

In the realm of engine performance, the significance of high-quality Con Rod Bearings cannot be overstated. These components play a crucial role in the smooth operation of internal combustion engines, directly affecting efficiency, power output, and overall durability. According to a recent report by the Engine Builder magazine, nearly 60% of engine failures are attributed to bearing-related issues, highlighting the vital role that Con Rod Bearings play in maintaining engine integrity. Proper lubrication and bearing materials are essential to reduce friction and wear, and advancements in technology have led to the introduction of innovative bearing designs that enhance oil retention and load distribution. As tuners and manufacturers strive for higher horsepower and efficiency, understanding the intricacies of Con Rod Bearings becomes imperative, not only for performance enthusiasts but also for ensuring the longevity and reliability of an engine.

The role of con rod bearings in enhancing engine efficiency is often overlooked, yet they are crucial components in ensuring smooth operation and optimal performance. These bearings are positioned between the connecting rod and the crankshaft, allowing for a critical balance between motion and friction. With the right con rod bearings, engines can operate at higher RPMs with reduced heat generation and wear. This reduction in friction not only prolongs engine life but also enhances fuel efficiency by minimizing energy loss during operation.

The role of con rod bearings in enhancing engine efficiency is often overlooked, yet they are crucial components in ensuring smooth operation and optimal performance. These bearings are positioned between the connecting rod and the crankshaft, allowing for a critical balance between motion and friction. With the right con rod bearings, engines can operate at higher RPMs with reduced heat generation and wear. This reduction in friction not only prolongs engine life but also enhances fuel efficiency by minimizing energy loss during operation.

Moreover, the quality of con rod bearings directly influences the engine's overall performance. High-quality bearings made from durable materials can withstand extreme conditions, providing better lubrication and stability. This leads to improved power transfer and throttle response, which are essential for both daily driving and high-performance applications. Investing in the best con rod bearings not only elevates engine efficiency but also contributes to a more reliable and powerful driving experience, making it a vital consideration for enthusiasts and everyday drivers alike.

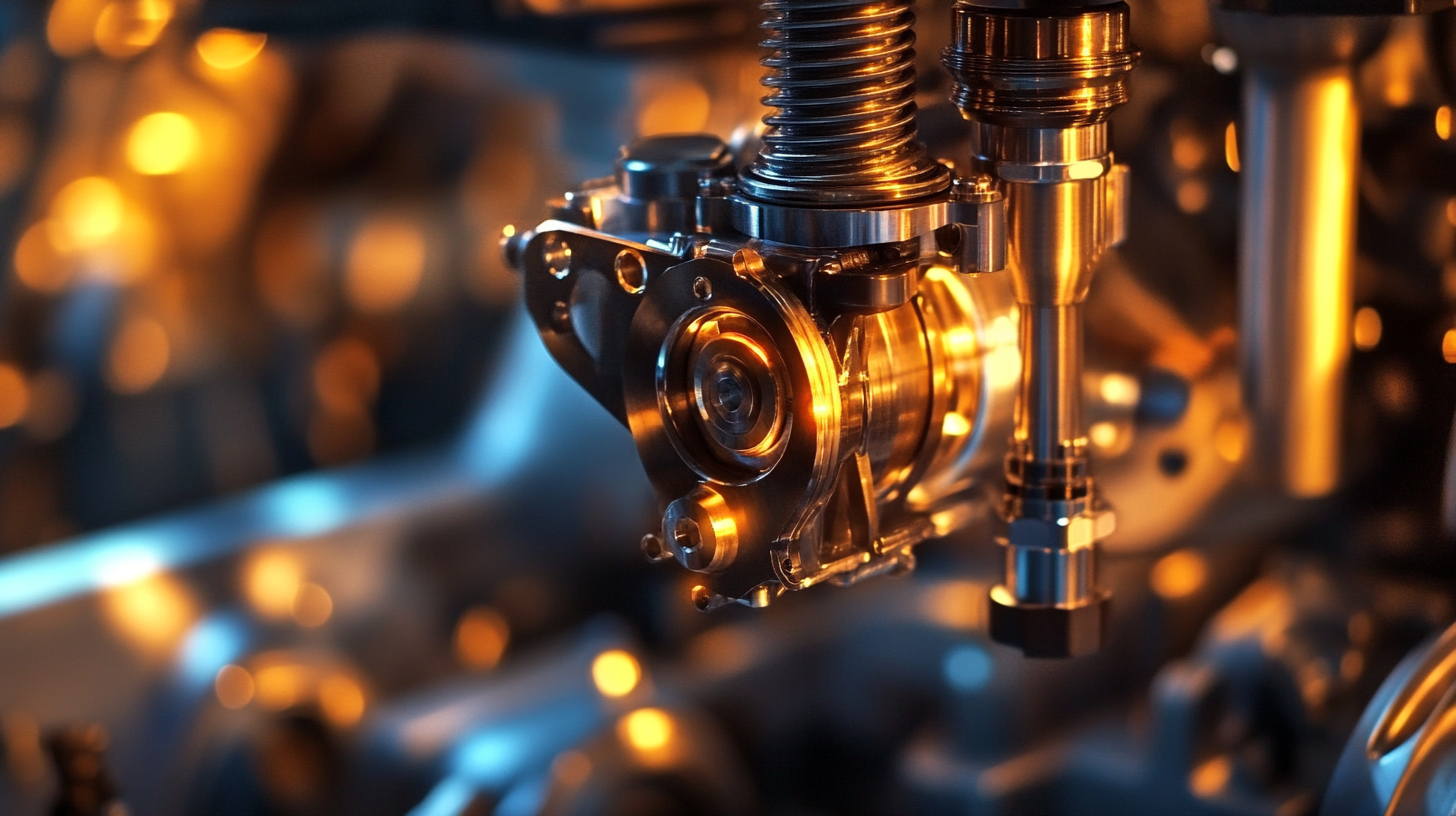

When selecting high-quality con rod bearings, certain key features can significantly impact engine performance. One of the most critical aspects is the bearing material. High-performance bearings are typically made from materials such as aluminum or copper-lead, which offer excellent tensile strength and resistance to wear. According to a report by the Society of Automotive Engineers (SAE), proper material selection can reduce friction coefficients by up to 30%, leading to improved engine efficiency and longevity.

Another crucial feature to consider is the surface finish of the bearings. A smoother finish can enhance oil retention, reducing the likelihood of metal-to-metal contact and wear. The American Society of Mechanical Engineers (ASME) emphasized that bearings with specialized surface treatments, such as phosphate coating or micro-polishing, can improve fatigue resistance by as much as 25%. Additionally, the design of the bearing, including its thickness and lubrication grooves, plays a vital role in ensuring optimal oil flow and heat dissipation, which are critical for high-performance engines operating under severe conditions. These features collectively ensure that con rod bearings perform reliably, maintaining engine health and maximizing power output.

| Feature | Importance | Materials Used | Recommended Clearance |

|---|---|---|---|

| Durability | Ensures long-lasting performance under stress | Copper, Aluminum, Bi-metal | 0.001 to 0.003 inches |

| Weight | Affects engine responsiveness and efficiency | Titanium, Aluminum Alloys | 0.0015 to 0.0025 inches |

| Surface Finish | Reduces friction, enhancing overall performance | High-polished steel or coated surfaces | 0.002 to 0.003 inches |

| Compatibility | Ensures proper fit for optimized performance | Steel, Composite Materials | 0.001 to 0.002 inches |

| Load Capacity | Critical for handling engine forces | Silicon bronze, Leaded bronze | 0.002 to 0.004 inches |

When it comes to engine performance, the selection of con rod bearings is crucial. Leading manufacturers in con rod bearing production, such as ACL, Clevite, and Vandervell, each bring unique advantages and technologies to the table. According to a 2022 study by the International Journal of Automotive Engineering, proper selection of bearings can enhance engine efficiency by up to 15%, significantly impacting overall vehicle performance. These manufacturers utilize advanced materials and innovative designs, which can minimize friction and wear under high-stress conditions.

One key factor to consider when choosing con rod bearings is the material composition. Many high-performance bearings feature a composite of copper, lead, and other metals, providing superior load-carrying capacity. For instance, ACL’s bearings are renowned for their patented multipurpose design that optimizes both durability and performance. As a tip, always consult the manufacturer's specifications to match the bearings with your engine’s requirements to prevent premature failure.

Additionally, attention should be paid to the installation process of con rod bearings. A report from the Society of Automotive Engineers highlights that improper installation can lead to up to 30% of bearing-related failures in engines. Therefore, it's essential to follow installation guidelines meticulously. For enthusiasts, investing in a professional installation service is often a wise choice to ensure every component is fitted correctly.

This chart illustrates the key metrics influencing the performance of con rod bearings in engine applications, highlighting the significance of performance, durability, cost, compatibility, and heat dissipation.

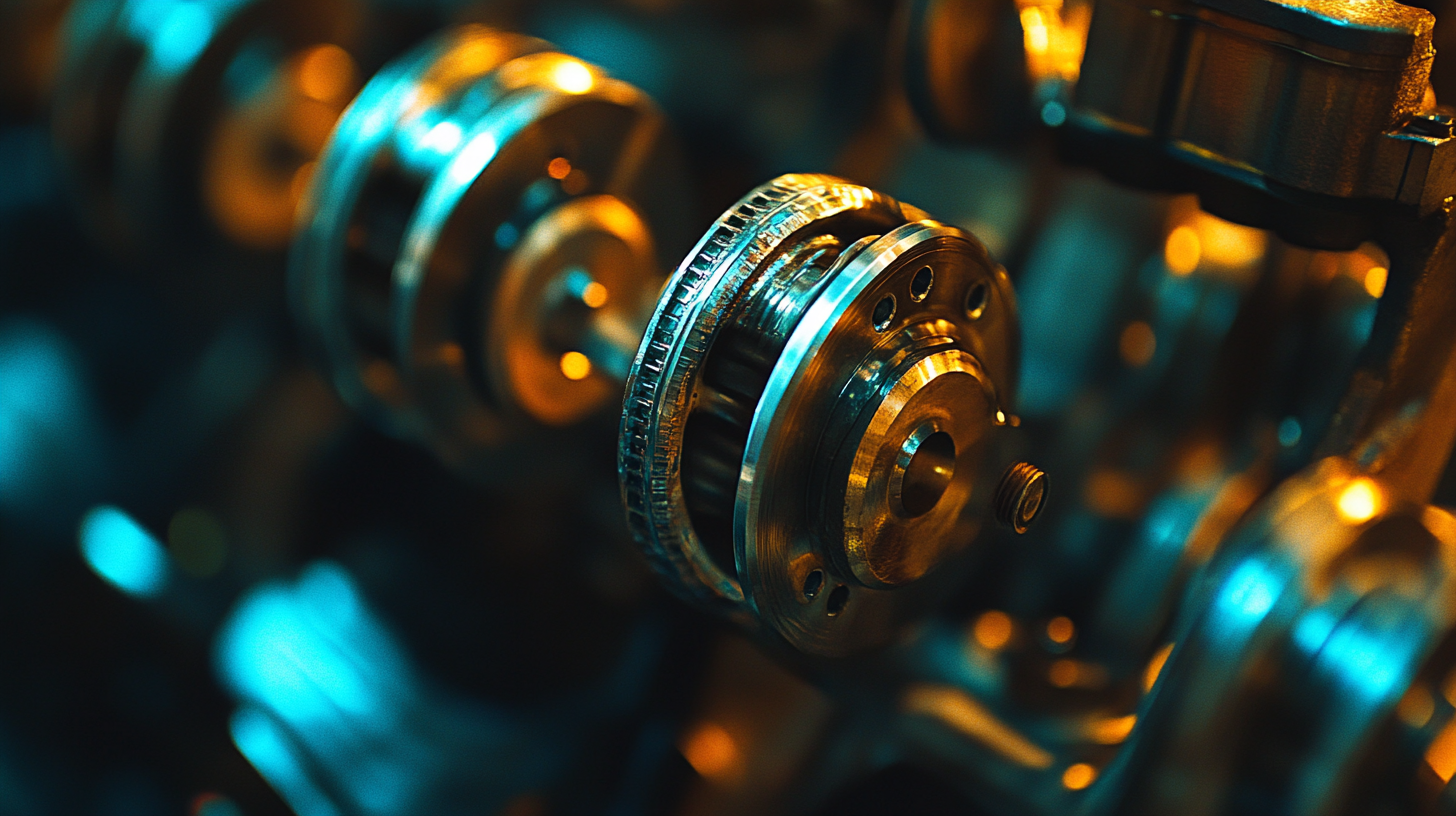

When selecting con rod bearings for engine performance, avoiding common mistakes is crucial to ensuring longevity and efficiency. One significant error is overlooking compatibility. Each engine model has specific requirements regarding bearing size, material, and design. For instance, opting for generic bearings may lead to improper fits, increasing the risk of premature failure, as highlighted by recent investigations into sudden engine failures in certain model years.

Another critical mistake is neglecting the importance of proper installation. Inadequate torque specifications or misalignment can lead to uneven wear, ultimately affecting performance and safety. Remember to always refer to manufacturer guidelines for installation procedures. As engine bearing technology advances, understanding these details can significantly impact longevity and performance.

**Tips:** Ensure that you research the specific requirements for your vehicle's engine before purchasing bearings, and always prioritize quality over cost. Additionally, consider seeking professional advice if you're unsure about the installation process, as even minor errors can have major consequences.

Con rod bearings play a crucial role in ensuring the smooth operation of an engine by minimizing friction between moving parts. Their impact on overall vehicle performance and longevity cannot be overstated, as they directly affect how an engine performs under various conditions. High-quality con rod bearings help maintain optimal oil flow, reduce wear, and enhance engine response, particularly in high-performance applications. This is especially relevant in the rapidly growing plain bearing market, projected to reach USD 20.33 billion by 2032, driven by the automotive industry's need for reliable and efficient components.

When considering the selection and installation of con rod bearings, it is essential to focus on materials and design. Advanced materials, such as polymer coatings, significantly improve the performance of engine bearings, protecting them from issues like oil starvation and metal-to-metal contact. These innovations ensure better reliability and elevate the engine's overall durability and performance in high RPM scenarios.

Tips: Always consult an experienced mechanic or technician when selecting con rod bearings to fit your specific engine application. Additionally, ensure proper installation and regular maintenance checks to maximize the lifespan and performance of your bearings. Finally, keep an eye on trends in engine bearing technology, as advancements can lead to improved vehicle performance and efficiency.