+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

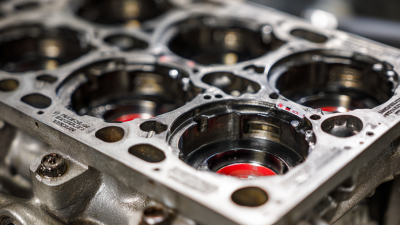

Maintaining your Engine Cylinder Head is crucial for overall vehicle performance. This component plays a key role in sealing the combustion chamber. Its efficiency directly impacts engine power and fuel consumption.

Neglecting the Engine Cylinder Head can lead to significant issues, such as overheating and loss of power. Regular checks and maintenance routines are essential. This includes inspecting for leaks, cracks, and proper torque settings. Even small issues can escalate quickly if overlooked.

Many vehicle owners underestimate this part's importance. We often focus on larger engine components while neglecting the Engine Cylinder Head. Addressing its condition proactively can save time and money. Remember, timely maintenance can prevent costly repairs down the road.

Engine cylinder head efficiency plays a crucial role in overall vehicle performance. A well-maintained cylinder head ensures better air and fuel flow, leading to improved combustion efficiency. According to industry reports, vehicles with optimized cylinder heads can achieve up to 10-15% more power output. This increase significantly impacts acceleration and fuel economy.

There are several factors contributing to the efficiency of an engine cylinder head. For example, the design of the combustion chamber affects how effectively fuel burns. A streamlined design can minimize turbulence, which enhances power generation. However, many vehicles fail to capitalize on this aspect due to neglect in maintenance. Regular checks can identify issues such as cracks or warping, which diminish efficiency and performance.

In addition, cooling systems are directly linked to cylinder head efficiency. Overheating can cause severe damage. A study by automotive engineers highlighted that maintaining optimal temperature can enhance performance metrics by up to 20%. Unfortunately, many drivers overlook the importance of these systems, leading to potential failures. Ignoring these details can result in costly repairs down the line.

This bar chart illustrates the varying impacts of engine cylinder head efficiency on key performance metrics in a vehicle. The data shows that horsepower and fuel efficiency benefit most significantly from optimal cylinder head conditions, while emissions and engine temperature are also affected but to a lesser degree.

Cylinder head damage can severely impact engine efficiency. Common causes include overheating, improper installation, and contamination. According to industry reports, nearly 30% of engine failures stem from cylinder head issues. Overheating can warp the metal, leading to seal failures and, ultimately, coolant leaks.

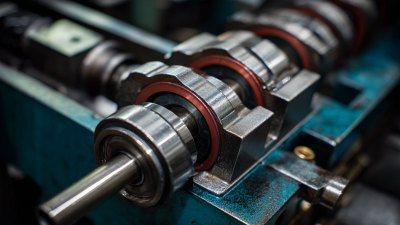

Contamination is another critical factor. Debris and dirt can enter the engine, creating wear. A study from the Society of Automotive Engineers found that 40% of internal engine damage results from insufficient filtration. This contamination affects performance and can lead to increased fuel consumption. Regular maintenance, including oil changes and filter checks, is vital.

Improper installation can create gaps, leading to pressure loss. Uneven torque can cause warping or cracking. Data highlights that nearly 25% of mechanics acknowledge this as a prevalent issue. These flaws not only undermine efficiency but can also compromise safety. Maintaining a close watch on these factors can save time and money in the long run.

| Tip Number | Maintenance Tip | Common Causes of Damage | Impact on Efficiency |

|---|---|---|---|

| 1 | Regularly Inspect for Cracks | Thermal Expansion, Overheating | Reduced Compression, Power Loss |

| 2 | Check for Warping | Improper Installation, Overheating | Loss of Sealing, Increased Emissions |

| 3 | Maintain Proper Cooling System | Coolant Leaks, Pump Failure | Overheating, Premature Engine Failure |

| 4 | Use Quality Engine Oil | Poor Lubrication, Contamination | Increased Friction, Reduced Efficiency |

| 5 | Inspect and Replace Gaskets | Age, Heat Exposure | Oil Leaks, Performance Drops |

| 6 | Keep Intake and Exhaust Ports Clean | Carbon Build-Up, Dirt | Reduced Airflow, Power Loss |

| 7 | Use Appropriate Fasteners | Incorrect Torque, Weak Materials | Potential Failures, Leakage |

| 8 | Avoid Engine Overheating | Radiator Issues, High Load | Severe Damage, Reduced Life Span |

| 9 | Perform Regular Tune-Ups | Neglect, Timing Issues | Power Loss, Higher Emissions |

| 10 | Monitor Engine Performance | Failure to Maintain, Driving Conditions | Lack of Responsiveness, Decreased Efficiency |

Maintaining your engine cylinder head is crucial for longevity and performance. Regular check-ups can prevent costly repairs later. For instance, a study by the Society of Automotive Engineers found that proper maintenance can extend engine life by up to 50%. Simple practices lead to significant results.

Tip one: Regularly check the coolant level. Low coolant can cause overheating. Overheating damages the cylinder head. Even a small leak can have severe consequences. Ensure your cooling system is in top shape.

Tip two: Use high-quality engine oil. It minimizes friction and keeps everything running smoothly. Research indicates that using premium oil can enhance engine efficiency by around 20%. Don’t ignore oil changes; they can save you from bigger problems.

Addressing small issues before they grow is essential. Cracks can develop, often unnoticed. Regular inspections help catch these early. Ignoring minor wear and tear can lead to complete head replacement.

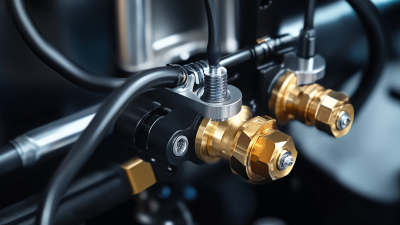

Maintaining an efficient cooling system is crucial for your engine cylinder head. Overheating can lead to serious damage. Regularly check coolant levels and ensure there are no leaks. An empty reservoir can cause catastrophic failure. Keep the cooling system clean and free from debris. Blockages can disrupt the flow of coolant.

Monitoring the temperature gauge is also important. If it rises unexpectedly, address the issue immediately. A faulty thermostat can interfere with proper cooling. It's important to replace worn-out parts without delay. Pay attention to the hoses and connections. They age over time and can crack or break.

Consider running a coolant flush regularly. This can prevent corrosion and improve flow. However, be cautious with overly aggressive cleaning solutions. Sometimes, these can harm the system. If unsure, consult a professional. Remember, consistent maintenance helps ensure optimal performance. Taking shortcuts now can lead to bigger problems later. Reflect on your practices; are they truly effective?

Maintaining engine cylinder head efficiency hinges significantly on using quality materials for repairs and replacements. Research indicates that a staggering 35% of cylinder head failures stem from subpar manufacturing. When dealing with such crucial components, it can be tempting to cut costs. However, this often leads to more significant issues down the line.

Utilizing materials like aluminum or cast iron, known for their durability, can enhance engine performance. Direct comparisons show that engines made with high-quality cylinder heads can achieve up to 10% more horsepower. Unfortunately, not everyone opts for these premium options, leading to avoidable inefficiencies. For instance, lower-grade gaskets may compromise sealing, resulting in coolant leaks and overheating.

It’s essential to consider the long-term consequences of the materials chosen. A study revealed that 50% of engine failures occur within the first year after inadequate repairs. Regular inspections and using trusted materials can prevent this. It’s vital to reflect on past choices—were they based on cost, or did they prioritize quality? The right materials not only enhance performance but can save on significant repair costs in the future.