+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

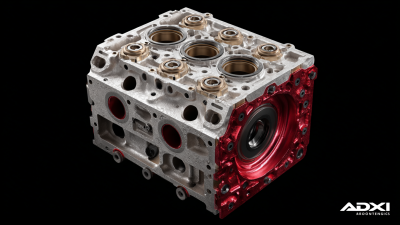

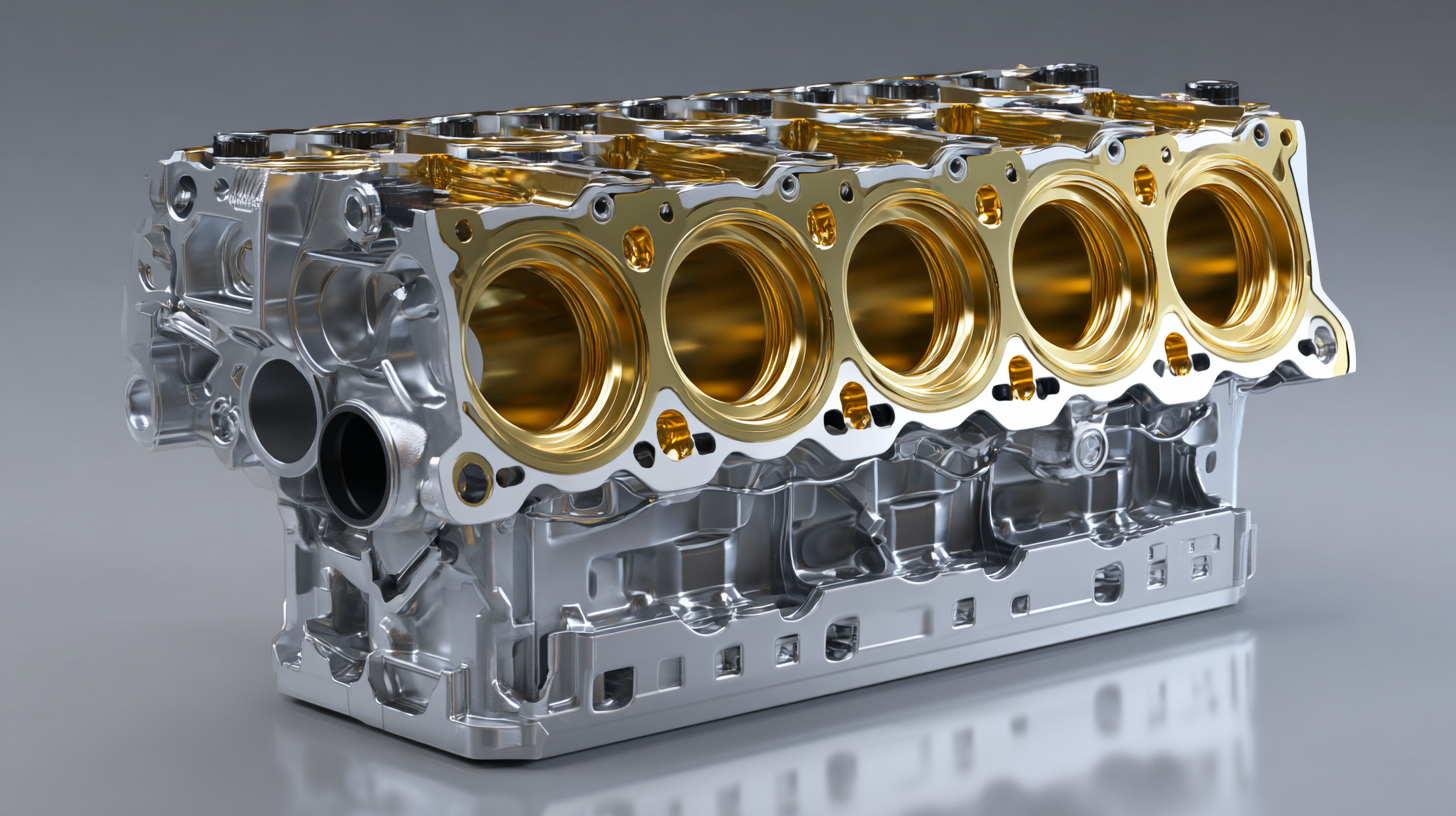

The engine cylinder block plays a pivotal role in modern automotive technology, serving as the foundation for internal combustion engines. According to the International Engine Manufacturers Association (IEMA), approximately 75% of the engine's weight is attributed to the cylinder block, highlighting its importance in the overall design and performance of vehicles. Technological advancements in materials and manufacturing processes have transformed engine cylinder blocks, enabling lighter, more durable, and thermally efficient designs. For instance, the adoption of aluminum alloy in cylinder block construction is projected to reduce the overall vehicle weight by up to 15%, improving fuel efficiency by 5-10% as reported by the Society of Automotive Engineers (SAE). As automotive manufacturers increasingly focus on sustainability and performance, understanding the specifications and innovations surrounding engine cylinder blocks is integral to ensuring compliance with stringent emissions regulations and enhancing engine performance.

The engine cylinder block plays a pivotal role in modern automotive technology, serving as the foundation for internal combustion engines. According to the International Engine Manufacturers Association (IEMA), approximately 75% of the engine's weight is attributed to the cylinder block, highlighting its importance in the overall design and performance of vehicles. Technological advancements in materials and manufacturing processes have transformed engine cylinder blocks, enabling lighter, more durable, and thermally efficient designs. For instance, the adoption of aluminum alloy in cylinder block construction is projected to reduce the overall vehicle weight by up to 15%, improving fuel efficiency by 5-10% as reported by the Society of Automotive Engineers (SAE). As automotive manufacturers increasingly focus on sustainability and performance, understanding the specifications and innovations surrounding engine cylinder blocks is integral to ensuring compliance with stringent emissions regulations and enhancing engine performance.

The evolution of engine cylinder blocks has been a pivotal aspect of automotive technology, reflecting advancements in materials and manufacturing processes. Initially, engine blocks were predominantly made from cast iron due to its excellent durability and thermal conductivity. This type of material allowed for robust construction but was relatively heavy, impacting vehicle performance and fuel efficiency. As automotive demands grew, the industry sought lighter alternatives, leading to the incorporation of aluminum alloys in engine block design.

Aluminum alloys have transformed the landscape of engine cylinder blocks, offering significant benefits over traditional cast iron. They are not only lighter but also provide improved thermal efficiency and resistance to corrosion. The use of aluminum helps reduce overall vehicle weight, enhancing performance and fuel economy, which is crucial in modern automotive engineering. Furthermore, advancements in alloy compositions and manufacturing techniques have enabled the production of stronger and more resilient blocks that meet the rigorous demands of contemporary engines, showcasing the continuous innovation within the industry.

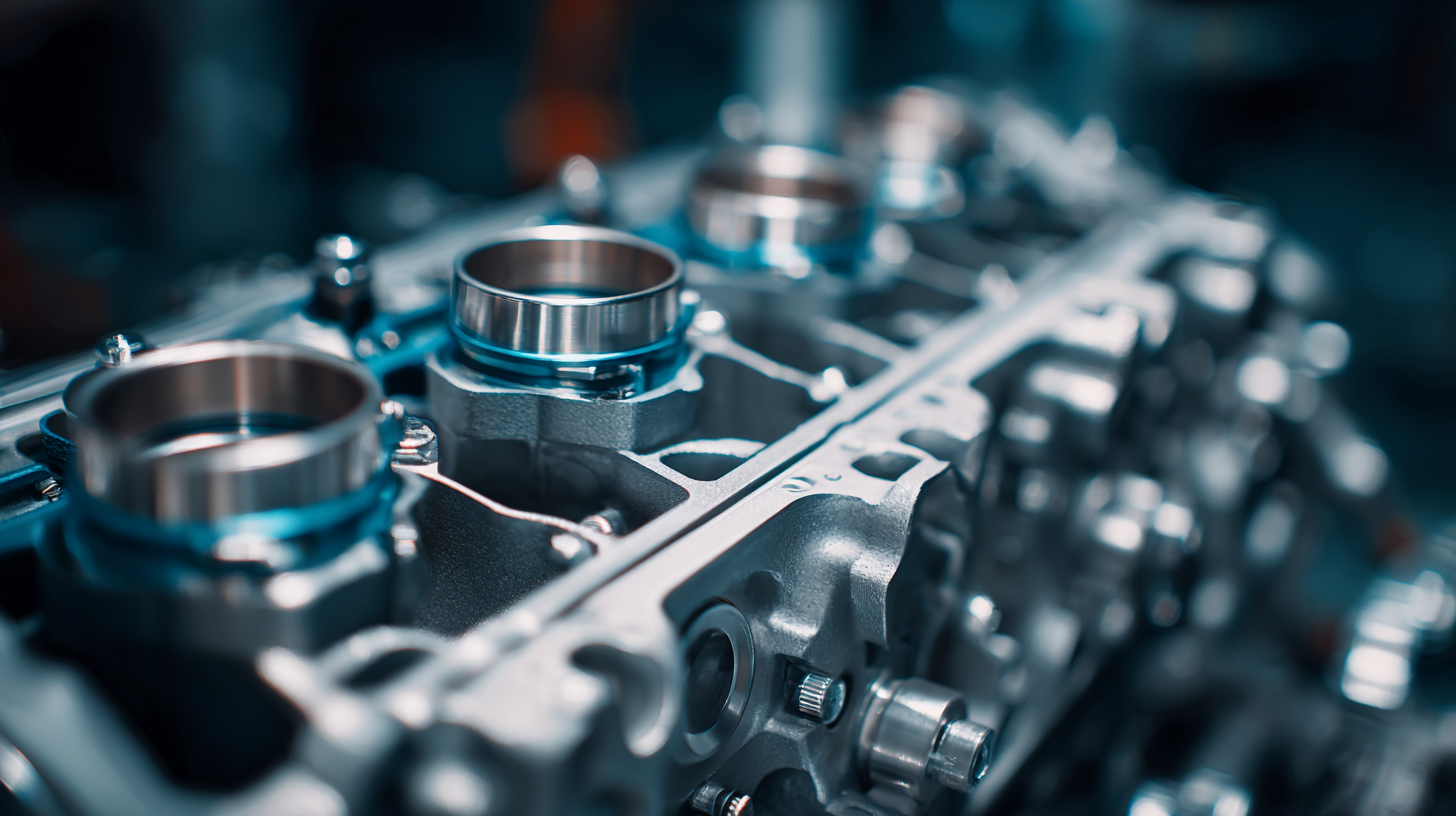

Innovative manufacturing techniques are revolutionizing the production of engine cylinder blocks, a critical component in modern automotive engines. Advanced methods such as additive manufacturing, also known as 3D printing, allow for complex geometries and lightweight designs that were previously impossible to achieve with traditional casting techniques. This shift not only enhances the overall performance of the cylinder block but also contributes to improved fuel efficiency and reduced emissions, aligning with the automotive industry’s drive toward sustainability.

Moreover, the integration of computer-aided design (CAD) and simulation technologies has significantly streamlined the development process. Engineers can now prototype cylinder block designs quickly, test them under various conditions virtually, and optimize for performance before physical production begins. Additionally, advancements in materials science have led to the use of stronger, lighter alloys, thereby increasing the durability and performance of engine components. This fusion of innovative manufacturing methods and cutting-edge materials is paving the way for more efficient and powerful automotive engines, ultimately shaping the future of the industry.

The design of engine cylinder blocks plays a pivotal role in enhancing fuel efficiency and meeting stringent emission standards in modern vehicles. Recent studies highlight that innovations in cylinder block design are crucial for optimizing thermal management and reducing weight, which in turn contribute to improved engine performance. The global automotive balance shaft market, valued at USD 15.13 billion in 2024, underscores the industry's focus on components that support efficient engine operation. With projections estimating a growth to USD 21.94 billion by 2032, it's evident that manufacturers are increasingly investing in technologies that elevate the efficiency of internal combustion engines while adhering to evolving emission regulations.

Moreover, advancements such as turbocharger matching and turbine design have shown significant potential in maximizing engine output and efficiency. For instance, systematic simulations have demonstrated how proper alignment between the engine and turbocharger can lead to better performance metrics. Additionally, the exploration of alternatives to traditional four-stroke engines may further enhance fuel efficiency, addressing the growing concerns over carbon emissions and environmental sustainability. This shift necessitates a reconsideration of engine designs and operational strategies, reflecting the ongoing commitment of the automotive industry to innovate for a cleaner, more efficient future.

| Engine Type | Cylinder Configuration | Fuel Efficiency (mpg) | Emissions (g/km CO2) | Material |

|---|---|---|---|---|

| Inline-4 | 4 Cylinders | 30 | 120 | Aluminum |

| V6 | 6 Cylinders | 25 | 180 | Cast Iron |

| Inline-6 | 6 Cylinders | 28 | 150 | Aluminum |

| V8 | 8 Cylinders | 22 | 200 | Cast Iron |

| Turbocharged Inline-4 | 4 Cylinders | 35 | 110 | Aluminum |

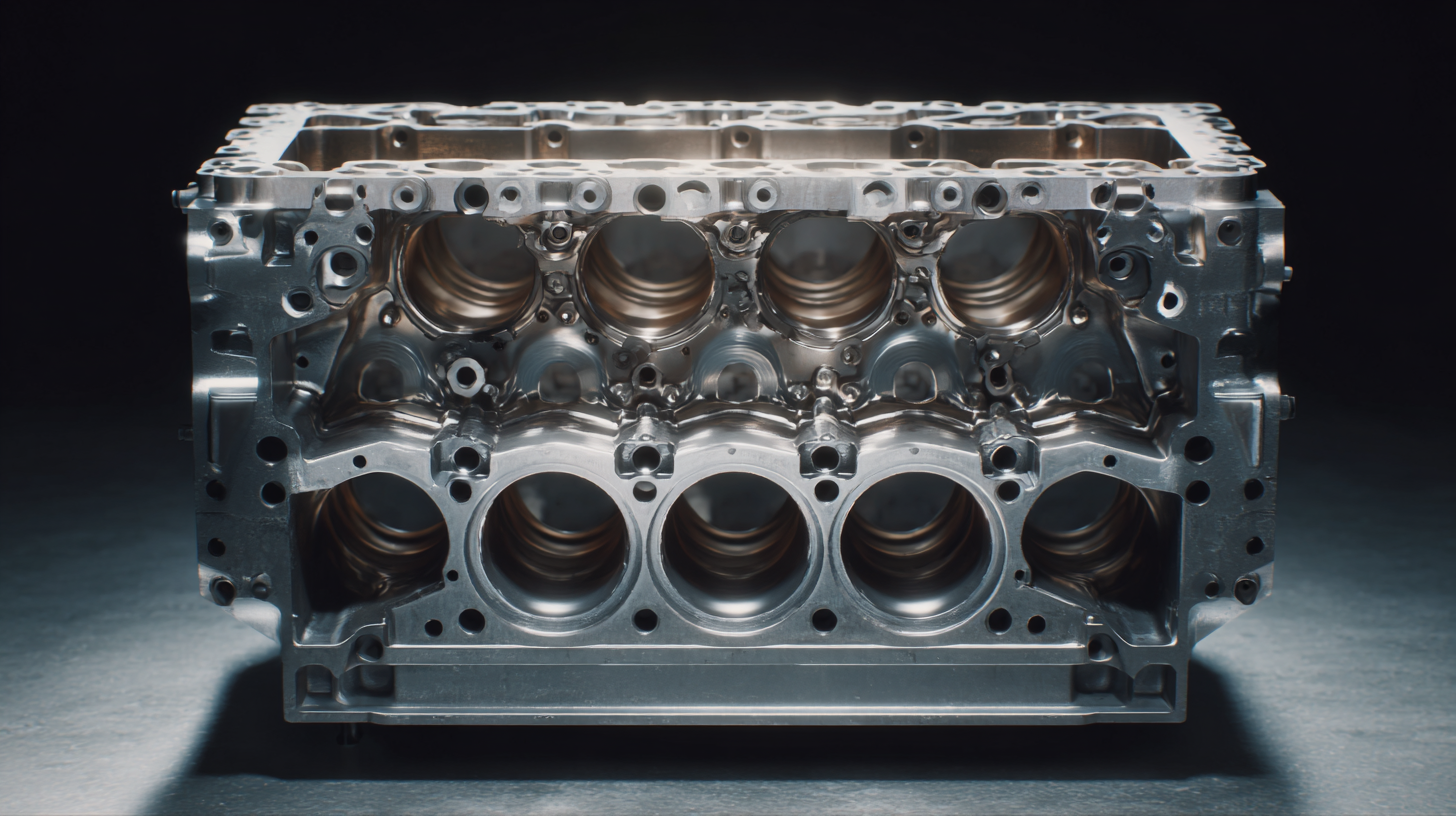

Engine cylinder block durability is a critical factor influencing the overall performance and longevity of modern vehicles. Key metrics such as tensile strength, fatigue resistance, and thermal conductivity play an essential role in assessing the resilience of these crucial components. Manufacturers adhere to rigorous industry standards, particularly those set by organizations like the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE). These standards dictate material specifications and testing protocols, ensuring that cylinder blocks can withstand the extreme pressures and temperatures encountered during engine operation.

In recent advancements, the use of high-strength aluminum alloys and modern casting techniques has enhanced the durability of engine cylinder blocks. By rigorously evaluating the microstructure and mechanical properties of these materials, automakers can achieve improved performance while reducing weight. Additionally, the integration of computational simulations aids in predicting cylinder block behavior under various operating conditions, allowing engineers to fine-tune designs for optimal durability. As automotive technology evolves, the focus on these metrics and standards remains vital for producing reliable and efficient engines that meet consumer demands and environmental regulations.

The evolution of engine cylinder block technology is becoming increasingly important as the automotive industry shifts towards electric vehicles (EVs). While traditional internal combustion engines will continue to play a role in hybrid models, the future of engine components must adapt to the new demands of efficiency and sustainability. Innovations such as lightweight materials and advanced manufacturing processes are being explored to enhance performance and reduce carbon footprints. Transitioning from heavy iron blocks to aluminum and composite options not only saves weight but also contributes to overall vehicle efficiency.

Tips: As engineers look toward the future, focusing on the integration of electric architecture within cylinder blocks can lead to significant advancements. This could mean designing blocks that accommodate electric motors more seamlessly or considering how thermal management can be optimized in hybrid systems. Innovations in cooling systems and battery integration will be crucial for maximizing both performance and longevity of EVs.

Moreover, as EV technology continues to improve, the concept of modular engine cylinder blocks may emerge, providing manufacturers with versatile solutions for a range of vehicle types. This adaptability can help make transitioning to electric technology more efficient, allowing for quicker production times and cost savings. Exploring these future trends will be vital for automotive manufacturers aiming to stay ahead in this rapidly evolving market.