+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

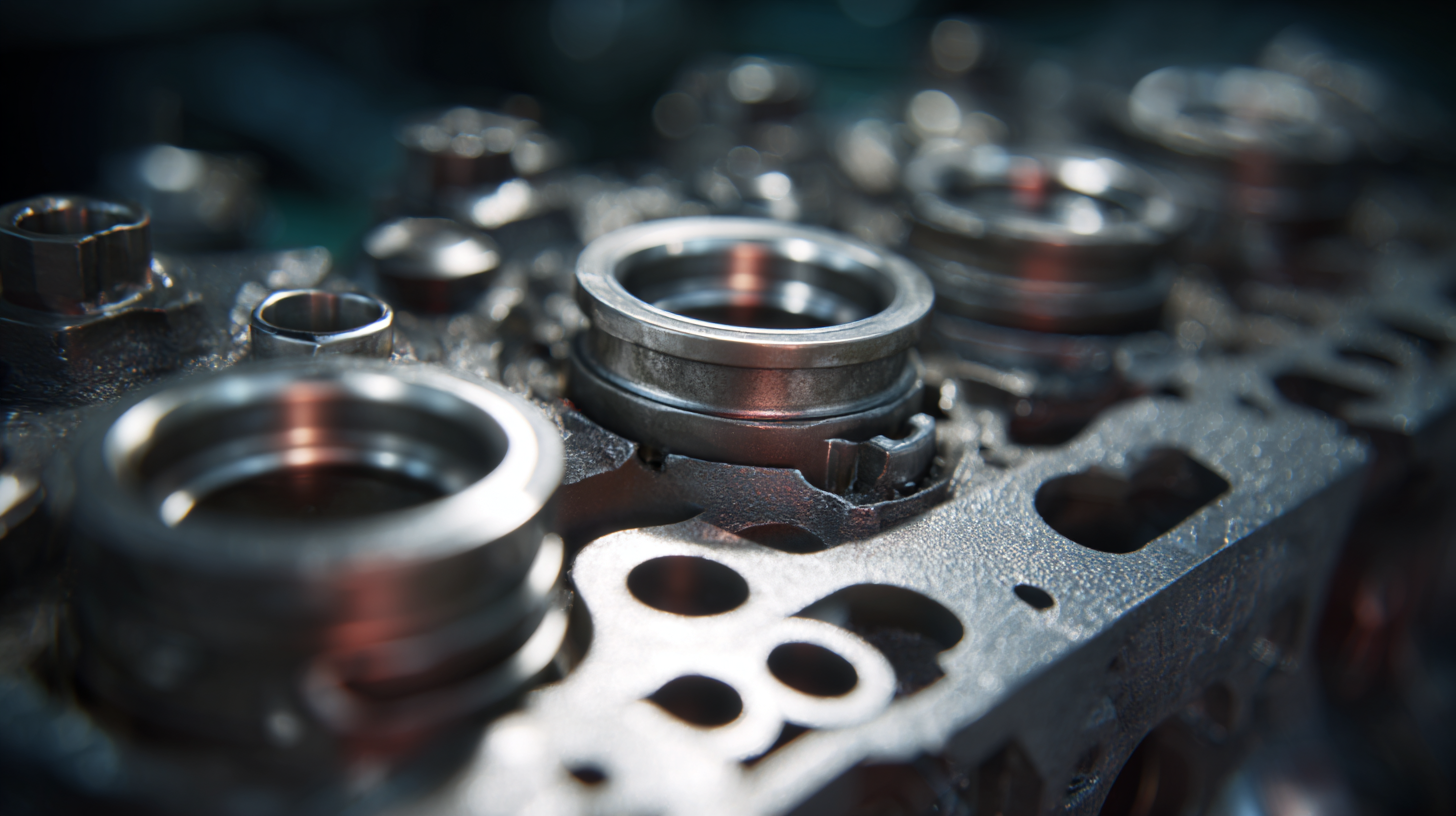

The cylinder head gasket plays a pivotal role in engine performance, acting as a critical seal between the engine block and cylinder head. As reported by the Engine Builders Association, around 30% of engine failures can be attributed to gasket-related issues, underlining the necessity of ensuring an optimal seal for maintaining compression and preventing coolant leaks. A compromised cylinder head gasket can lead to severe engine problems, including overheating and loss of power, impacting overall vehicle reliability and efficiency.

The cylinder head gasket plays a pivotal role in engine performance, acting as a critical seal between the engine block and cylinder head. As reported by the Engine Builders Association, around 30% of engine failures can be attributed to gasket-related issues, underlining the necessity of ensuring an optimal seal for maintaining compression and preventing coolant leaks. A compromised cylinder head gasket can lead to severe engine problems, including overheating and loss of power, impacting overall vehicle reliability and efficiency.

According to the Automotive Repair Association, addressing cylinder head gasket failures early can save car owners up to 40% in repair costs, making it essential for automotive professionals and enthusiasts alike to understand the nuances of this crucial component. By grasping the importance of the cylinder head gasket, one can appreciate its influence on engine longevity and performance, ultimately contributing to more informed maintenance decisions.

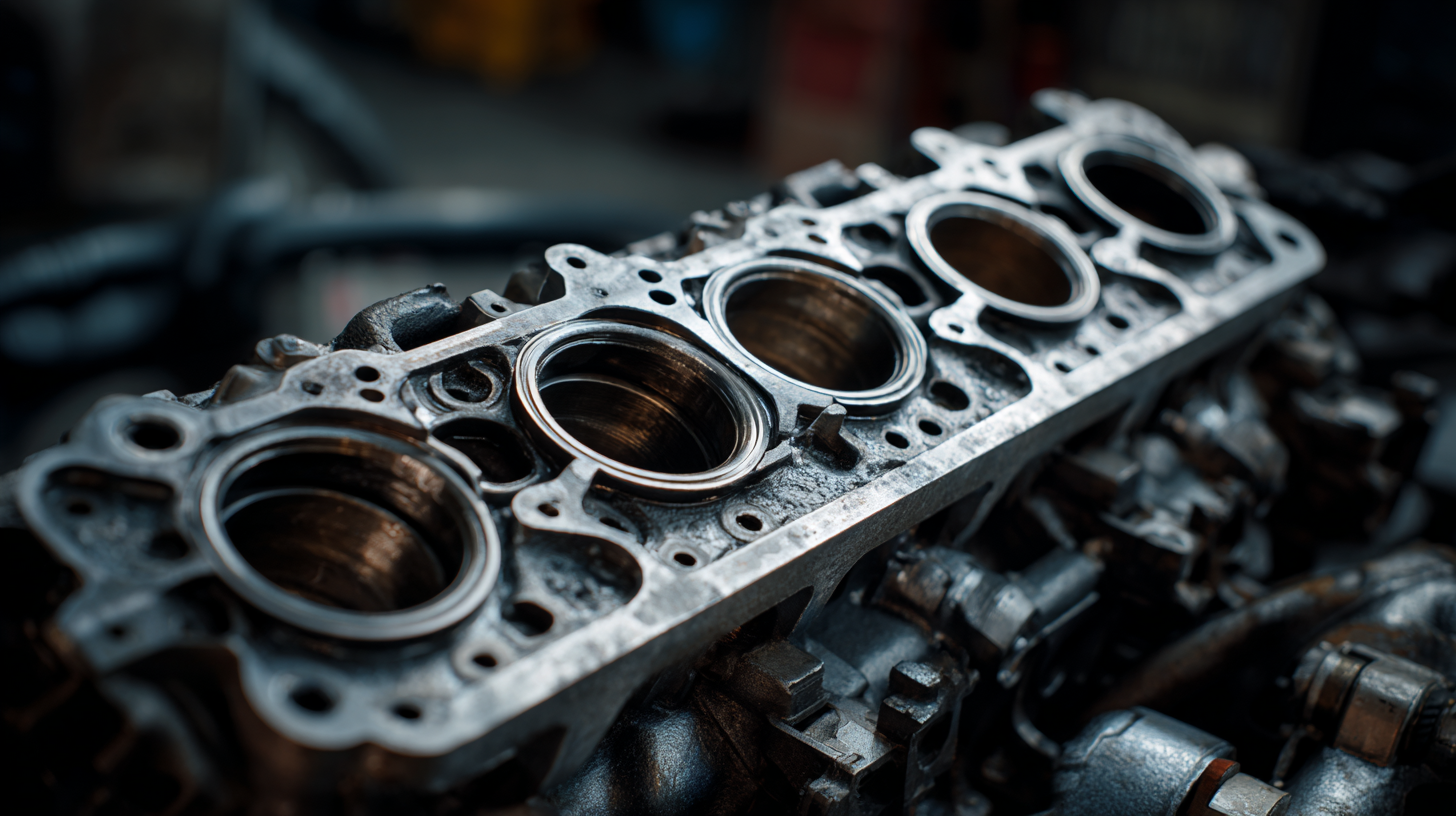

Cylinder head gaskets play a pivotal role in ensuring engine efficiency by creating a vital seal between the cylinder head and engine block. This seal prevents coolant and engine oil from mixing and helps maintain optimal compression within the combustion chamber. Any failure in the gasket can lead to engine overheating, decreased performance, and ultimately, costly repairs. According to industry reports, engine failures caused by gasket issues account for a significant portion of repair costs, emphasizing the need for high-quality gaskets in both OEM and aftermarket segments.

Tips: Regularly check for signs of coolant leaks or oil spots, which may indicate a failing gasket. Keeping an eye on your engine's temperature gauge can also help catch potential gasket failures before they escalate.

Additionally, advancements in materials and engineering have significantly improved the longevity and performance of gaskets. For example, modern gaskets now utilize composite materials that can withstand higher temperatures and pressures, making them essential for high-performance engines, such as the renowned inline-6 engines seen in popular sports cars. Investing in high-grade gaskets not only enhances engine efficiency but also contributes to overall vehicle reliability.

Tips: When replacing a gasket, consider utilizing OEM specifications and installation techniques to ensure a proper seal and optimal performance. Regular maintenance and timely replacements can help extend the life of your engine components.

| Dimension | Value | Impact on Performance |

|---|---|---|

| Material Type | Composite, Metal | Durability and thermal resistance |

| Thickness | 0.5 - 2.0 mm | Sealing effectiveness |

| Compression Ratio | 8:1 - 12:1 | Impact on power and efficiency |

| Installation Torque | 60 - 100 Nm | Affects sealing integrity |

| Operating Temperature | -40°C to 200°C | Influences material choice |

| Failure Rate | 1 - 2% | Impact on overall engine longevity |

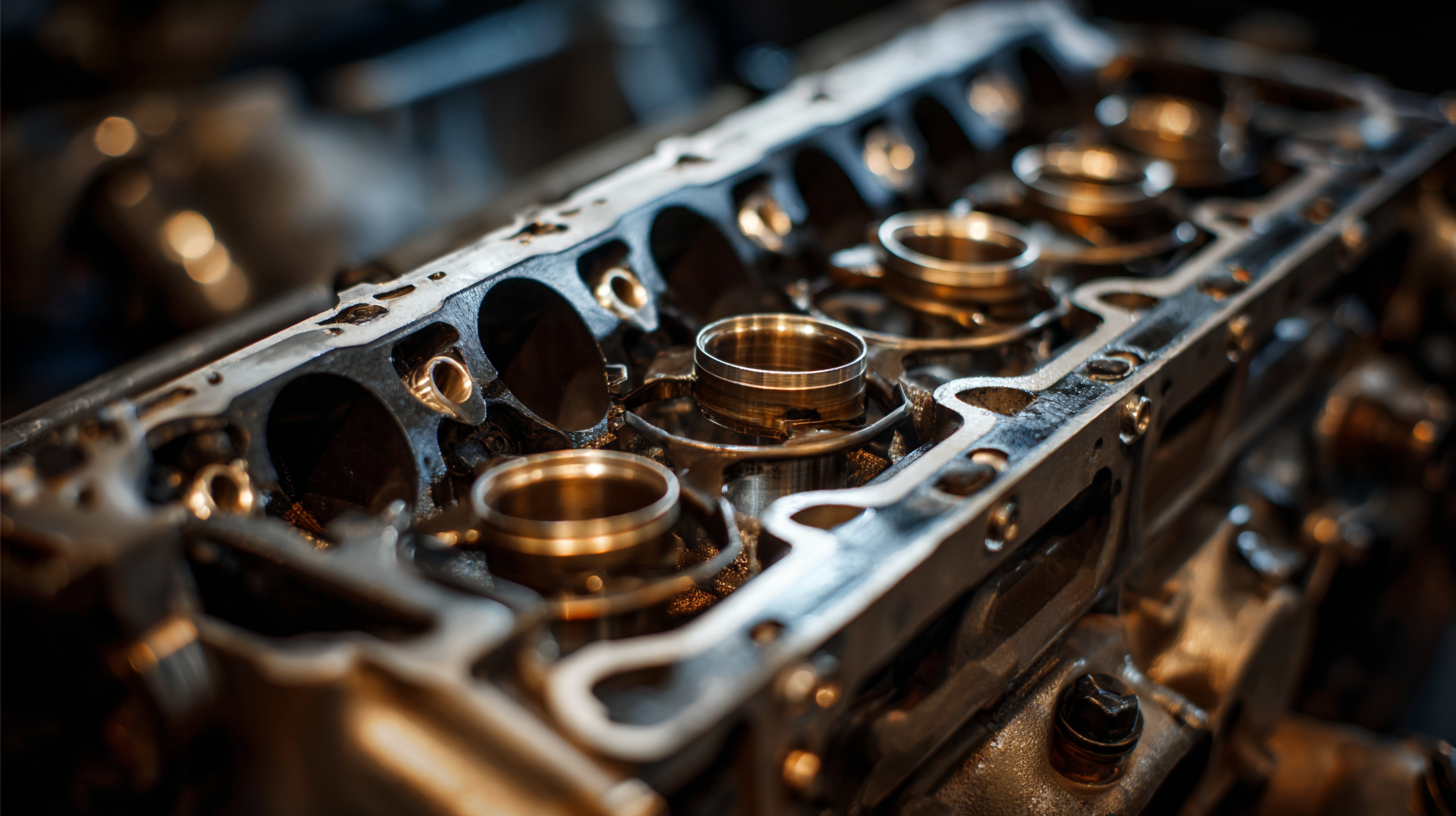

Cylinder head gaskets play a critical role in the overall performance of an engine. First and foremost, they create a tight seal between the cylinder head and the engine block, ensuring that combustion gases remain contained within the combustion chamber. This containment is vital for maintaining efficient engine operation, as any leaks can result in a loss of power and increased fuel consumption. A properly functioning head gasket allows for optimal pressure during combustion, directly affecting engine acceleration and responsiveness.

Additionally, cylinder head gaskets help maintain the proper coolant and oil separation. By preventing leakage between the coolant passages and the engine oil, they ensure that the engine remains lubricated effectively while also preventing overheating. Over time, a failing head gasket can lead to serious engine damage, including warped cylinder heads and blown engines. Therefore, understanding the importance of high-quality cylinder head gaskets is essential for vehicle performance and longevity, as they not only enhance efficiency but also protect the engine from potential catastrophic failures.

Diagnosing common cylinder head gasket failures is essential for maintaining optimal engine performance. These failures can manifest in various symptoms, including overheating, loss of power, and white smoke from the exhaust. Common causes of head gasket failure often include engine overheating due to insufficient coolant, which can lead to warping or cracking of the gasket. Regular inspections can help catch early signs of failure, such as coolant leaks or milky oil, which indicate contamination from coolant mixing with engine oil.

Recent reports highlight a troubling trend in engine reliability, particularly with certain models that have shown significant issues, often related to head gasket integrity. For instance, one mechanic reported problems with a vehicle that began misfiring—an issue frequently linked to head gasket failures. Other vehicles have faced similar problems, with premature failures noted in specific brands, raising concerns among owners. Identifying the symptoms early can save not only costly repairs but also prevent potential engine failures, emphasizing the importance of head gasket health in overall vehicle maintenance.

Maintaining cylinder head gaskets is crucial for ensuring optimal engine performance and longevity. Regular inspections should be conducted to check for signs of wear or damage, such as leaks or misfires. Addressing minor issues early can prevent more extensive damage to the engine, which often results in costly repairs. It is also advisable to monitor engine temperature and fluid levels consistently to catch any anomalies that could indicate a failing gasket.

In addition to routine checks, following manufacturer-recommended maintenance schedules can significantly extend the life of your cylinder head gasket. This includes regular oil changes and using high-quality fluids that meet the engine's specifications. It's also important to ensure that the engine is not overheated, as excessive temperatures can compromise the integrity of the gasket. Employing proper torque specifications during installation or replacement is vital, as improper installation can lead to gasket failure, leading to serious engine complications. Implementing these best practices not only enhances performance but also contributes to the overall health of the engine.

Cylinder head gaskets play a crucial role in the overall performance of an engine, significantly impacting fuel economy and emissions. A properly sealed gasket ensures maximum compression within the combustion chamber, leading to more efficient fuel combustion. According to a report by the Environmental Protection Agency, a malfunctioning head gasket can decrease fuel economy by as much as 15%, resulting in increased operational costs and higher emissions of greenhouse gases. This highlights the importance of regular maintenance and timely replacement of gaskets to maintain optimal engine performance.

Tip: Regularly check for symptoms of a failing gasket, such as coolant leaks or engine overheating, to prevent further damage and maintain efficiency.

Moreover, the importance of cylinder head gaskets extends to meeting stringent emission standards. A compromised gasket can allow exhaust gases to escape, affecting the effectiveness of catalytic converters and resulting in higher emissions of NOx and CO2. A study by the Society of Automotive Engineers found that faulty gaskets contribute to a 10% increase in pollutant emissions, showing the potential environmental impact. Ensuring that your engine’s head gasket is functioning correctly not only saves fuel but also helps in reducing your carbon footprint.

Tip: When considering a gasket replacement, opt for high-quality materials that offer superior sealing properties to enhance both fuel efficiency and emissions control.