+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

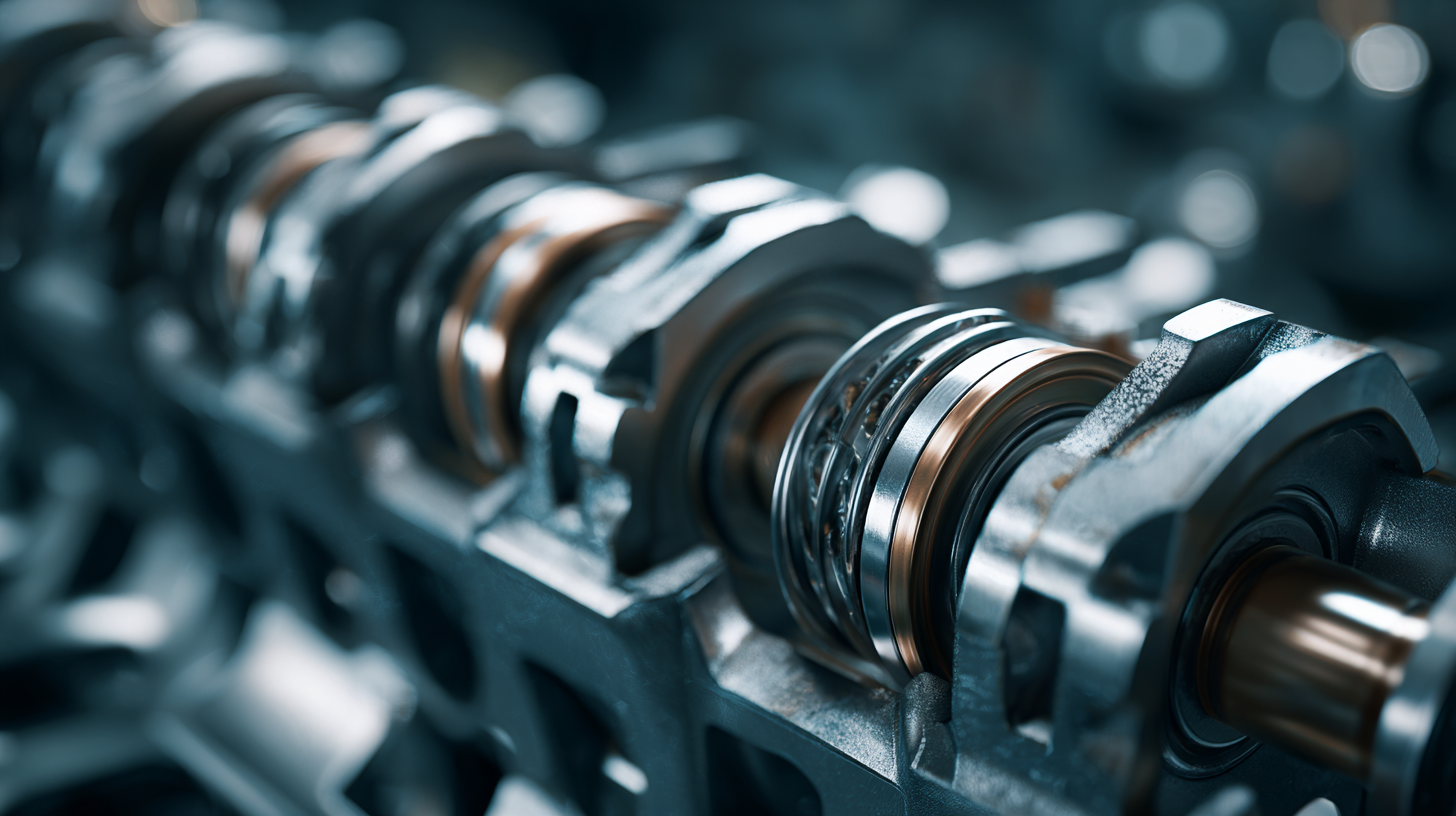

The crankshaft bearing is a critical component in an engine, playing a pivotal role in maintaining performance and longevity. Research indicates that approximately 70% of all engine failures are attributed to bearing-related issues, emphasizing the necessity for high-quality crankshaft bearings. According to market analysis by Grand View Research, the global automotive bearings market is expected to reach $20 billion by 2025, with a significant portion driven by advancements in engineering and materials for crankshaft bearings. Proper lubrication and precise alignment of crankshaft bearings can lead to improved fuel efficiency, reduced emissions, and enhanced overall performance. Understanding their importance not only aids in vehicle maintenance but also highlights the technological evolution in bearing design, which is crucial for the automotive industry’s advancement towards sustainability and reliability.

Crankshaft bearings play a crucial role in enhancing engine efficiency by reducing friction and ensuring smooth operation of internal combustion engines. These bearings support the crankshaft, allowing it to rotate freely while maintaining alignment with other engine components. High-quality crankshaft bearings minimize energy loss due to friction, ultimately improving the overall performance and fuel efficiency of the engine. As manufacturers strive to meet stringent emission regulations, the importance of optimizing crankshaft bearings cannot be overstated.

Tips for selecting the right crankshaft bearings include considering the type of engine and performance requirements. High-performance applications may benefit from advanced materials or coatings that offer better wear resistance and thermal stability. Additionally, ensuring proper installation is key—misalignment or inadequate lubrication can lead to premature bearing failure. Regular maintenance and inspections can further enhance the longevity and effectiveness of crankshaft bearings, keeping engines running smoothly and efficiently.

High-quality crankshaft bearings are essential for optimizing engine performance, providing a variety of benefits that can significantly enhance durability and efficiency. One of the primary advantages of these bearings is their ability to reduce friction, which not only helps in maintaining optimal engine temperatures but also improves fuel efficiency. This reduction in friction translates to less wear on engine components, thereby extending the lifespan of both the crankshaft and the engine as a whole.

Another crucial benefit is the improved load distribution that high-quality crankshaft bearings offer. By efficiently managing the weight and forces exerted on the engine, these bearings help prevent premature failure and ensure smooth operation under various conditions. Additionally, they play a vital role in noise reduction, contributing to a quieter engine performance—a factor that is increasingly valued by consumers. Overall, investing in superior crankshaft bearings is an integral step for anyone looking to enhance their vehicle's performance and reliability.

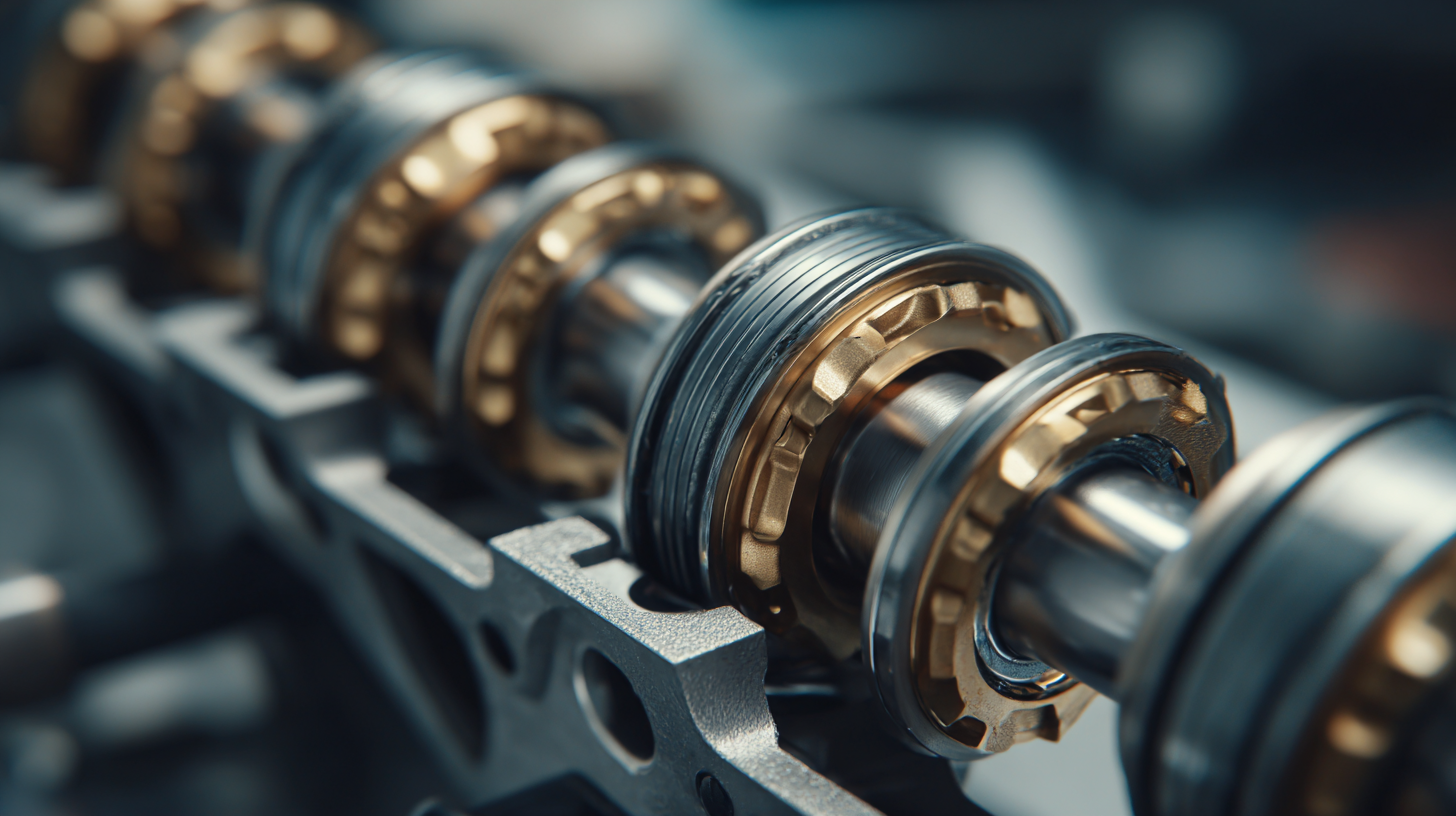

Choosing the right crankshaft bearings is crucial for optimizing engine performance and longevity. When selecting bearings, it’s essential to consider factors such as material, size, and load capacity. Bearings made from high-quality materials, such as aluminum or copper-lead alloys, offer superior wear resistance and heat dissipation, which can significantly reduce friction and enhance engine efficiency. Additionally, ensuring that the bearings have the correct size that matches the crankshaft and the engine block is vital for preventing problems like misalignment or excessive play.

Another key aspect is understanding the load capacity of the bearings. Depending on the engine's intended use—be it performance racing or everyday driving—the requirements for bearing strength will vary. It’s advisable to consult the manufacturer's specifications and choose bearings that can withstand the anticipated stress levels. Additionally, consider features such as surface treatments or coatings, which can further enhance durability and reduce operational wear. By carefully evaluating these factors, you can select the ideal crankshaft bearings that not only meet your engine's requirements but also contribute to improved overall performance.

Crankshaft bearings play a critical role in facilitating smooth movement within an engine. When these bearings begin to wear, it can lead to a range of symptoms that directly impact engine performance. One of the most common signs of worn crankshaft bearings is an unusual knocking sound emanating from the engine, especially when it is idling. This noise can indicate insufficient lubrication or improper clearance between the bearings and journals, leading to further damage if not addressed promptly.

Crankshaft bearings play a critical role in facilitating smooth movement within an engine. When these bearings begin to wear, it can lead to a range of symptoms that directly impact engine performance. One of the most common signs of worn crankshaft bearings is an unusual knocking sound emanating from the engine, especially when it is idling. This noise can indicate insufficient lubrication or improper clearance between the bearings and journals, leading to further damage if not addressed promptly.

Additionally, you may notice oil pressure fluctuations on the gauge. This is another red flag that signals potential issues with the crankshaft bearings. If the bearings have worn down significantly, they can cause oil to leak, affecting the oil delivery to critical engine components. It’s essential to pay attention to these warning signs, as neglect may result in catastrophic engine failure.

Tips: Regularly check your vehicle's oil levels and ensure timely oil changes to maintain optimal lubrication. If you hear strange noises or notice drops in oil pressure, consult a professional mechanic immediately to diagnose any potential issues with crankshaft bearings. Investing in preventive maintenance can ultimately save you from expensive repairs down the line.

Proper maintenance of crankshaft bearings is crucial for optimizing engine performance and extending their lifespan. Regularly checking oil levels and ensuring the use of high-quality lubricants can significantly reduce wear and tear. It’s essential to keep the oil clean and change it at recommended intervals to prevent debris accumulation, which can cause premature bearing failure. Additionally, monitoring engine temperatures can help identify potential issues before they escalate, allowing for timely interventions.

Proper maintenance of crankshaft bearings is crucial for optimizing engine performance and extending their lifespan. Regularly checking oil levels and ensuring the use of high-quality lubricants can significantly reduce wear and tear. It’s essential to keep the oil clean and change it at recommended intervals to prevent debris accumulation, which can cause premature bearing failure. Additionally, monitoring engine temperatures can help identify potential issues before they escalate, allowing for timely interventions.

Another effective way to prolong the life of crankshaft bearings is through routine inspections. Mechanics should pay close attention to any unusual noises or vibrations during engine operation, as these can be indicators of bearing distress. Furthermore, adhering to manufacturer guidelines for load capacity can prevent excessive stress on the bearings. Implementing these maintenance tips not only enhances engine efficiency but also saves on costly repairs in the long run.