+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

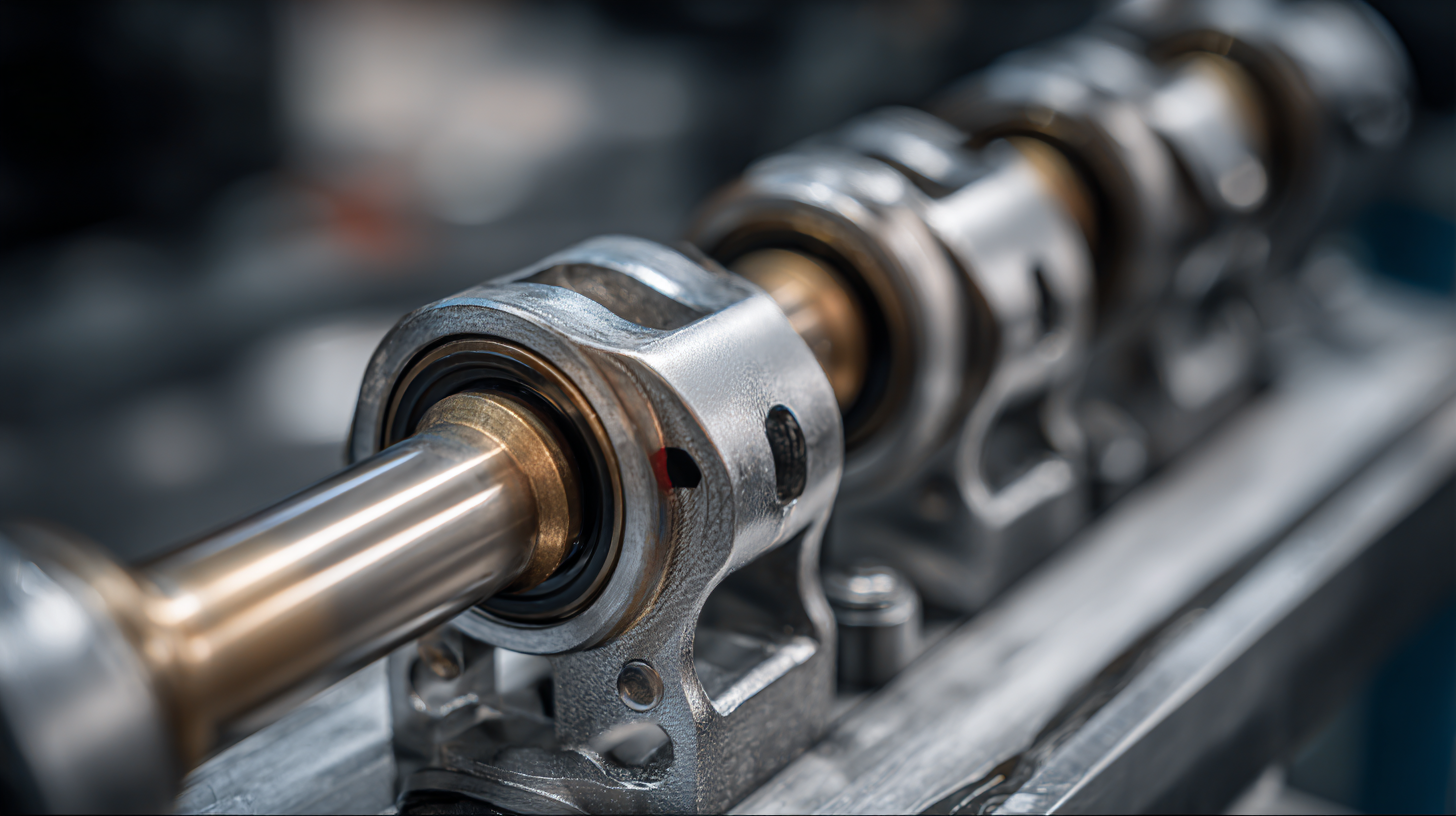

The design of connecting rods plays a crucial role in the overall performance and efficiency of an engine. According to a report by the Society of Automotive Engineers, approximately 20% of an engine's overall weight is attributed to its connecting rods, which significantly influences not only power output but also fuel efficiency and longevity. With advancements in materials and engineering practices, various types of connecting rod designs have emerged, including forged, cast, and lightweight options, each presenting unique benefits and trade-offs. For example, forged connecting rods are often preferred in high-performance applications for their superior strength-to-weight ratio, while cast rods may be more economical for everyday vehicles. Understanding these differences and their implications on engine dynamics is essential for both manufacturers and automotive enthusiasts alike, as proper selection can lead to enhanced performance metrics and reduced mechanical failures in various operational conditions.

The evolution of connecting rod designs has played a crucial role in enhancing engine performance across various applications, particularly in the context of off-road vehicles. The latest advancements showcase how manufacturers are integrating innovative materials and engineering techniques to optimize strength and reduce weight. Recent studies indicate that modern materials like titanium and high-strength steel can improve the durability of connecting rods while also providing a significant weight-saving advantage—often in the range of 10 to 20 percent over traditional designs. This weight reduction can lead to improved responsiveness and acceleration, crucial for off-road dynamics.

In the latest developments, a new two-stroke engine with an electric start is being introduced, marking a significant shift in engine design. This innovation not only demonstrates the importance of connecting rod efficiency but also reflects how manufacturers are embracing electric technology alongside traditional combustion engines. Reports suggest that optimizing the connecting rod geometry can enhance the power delivery and overall engine efficiency by 5 to 15 percent, showcasing how even subtle changes in connecting rod design can have a profound impact on vehicle performance. As the industry continues to push the boundaries of what is possible, the evolution of connecting rods remains a critical focus for engineers aiming to deliver superior performance in competitive scenarios.

Connecting rods play a crucial role in an engine's performance, and the materials used in their construction can significantly influence durability and efficiency. Traditional connecting rods were often made of cast iron, but advancements in materials have brought about alternatives such as aluminum and forged steel. According to a report by the Society of Automotive Engineers (SAE), the use of forged steel connecting rods can increase strength by up to 25% compared to those made from cast iron, allowing for higher RPMs and greater power output in performance engines.

Furthermore, aluminum connecting rods offer benefits in terms of weight savings. A study from the International Journal of Automotive Engineering reveals that reducing the weight of connecting rods by 20% can lead to an increase in engine responsiveness and fuel efficiency by up to 5%. This is particularly important in high-performance applications where every gram counts. The choice of materials, therefore, not only affects the strength and reliability of connecting rods but also plays a pivotal role in the overall performance and efficiency of modern engines.

The geometry of connecting rods in internal combustion engines plays a crucial role in influencing performance metrics such as engine efficiency and power output. Recent advancements in engine design reveal that optimizing the connecting rod's design can yield significant improvements in power distribution and durability. For instance, variable-length intake manifolds have been shown to increase volumetric efficiency in gasoline engines by as much as 15%, directly impacting power output by ensuring optimal air-fuel mixing during combustion.

Furthermore, the design of the combustion chamber geometry is pivotal for maximizing combustion efficiency and minimizing emissions. Studies utilizing multi-objective genetic algorithms indicate that refined combustion chamber shapes can improve overall efficiency by up to 10%. Such enhancements are essential, especially considering the global push for lower emissions and better fuel economy. The interplay between connecting rod design, engine geometry, and the overall thermodynamic cycle encapsulates the ongoing evolution in automotive engineering aimed at achieving high performance while adhering to increasingly strict environmental regulations.

When selecting connecting rods, two prominent designs stand out: I-Beam and H-Beam. Both designs are engineered to endure high-stress conditions, yet their structural compositions lead to significant differences in engine performance. I-Beam connecting rods are favored in applications requiring lightweight components, as their design reduces mass without sacrificing strength. This characteristic can lead to quicker revs and improved throttle response, making them suitable for high-performance engines. According to a report by the Society of Automotive Engineers, engines utilizing I-Beam rods demonstrated a 5% increase in horsepower due to reduced reciprocating mass.

On the other hand, H-Beam connecting rods are known for their superior strength and rigidity, making them the go-to choice for extreme power applications, such as racing. The wider base and taller cross-section offer enhanced resistance to bending and twisting, which is crucial under high torque loads. A study by Engine Labs highlighted that engines equipped with H-Beam rods achieved a 15% improvement in durability during sustained high RPM operation, confirming their reliability in a demanding environment.

**Tip:** When choosing between I-Beam and H-Beam connecting rods, consider your engine's specific needs. If you prioritize acceleration and weight savings for a performance vehicle, I-Beam may be preferable. However, for applications focused on durability and reliability, especially in high-output environments, H-Beam rods could be the better investment. Always ensure compatibility with your engine's overall design to optimize performance.

This chart illustrates the performance differences between I-Beam and H-Beam connecting rods in terms of weight, strength, stiffness, and cost. The data demonstrates how each design impacts engine performance characteristics.

When it comes to high-performance engines, the choice of connecting rod design can have a significant impact on overall performance and efficiency. Recent tests conducted by the Society of Automotive Engineers (SAE) reveal that lighter connecting rods can reduce overall engine weight and improve throttle response, enabling quicker acceleration. For example, a study found that using forged aluminum connecting rods can result in a weight reduction of up to 15% compared to traditional cast iron rods, which helps decrease rotational mass and enhances power delivery.

Nonetheless, this performance increase must be balanced with durability. Engine manufacturers have noted that while lightweight models provide incredible performance benefits, they may not withstand the same levels of stress as heavier counterparts under extreme conditions. A report from the Engine Manufacturers Association highlights that high-stress applications often benefit from steel connecting rods, which, although heavier, can endure higher power outputs without failing.

Tips: For those looking to optimize engine performance, consider the specific application. If speed is paramount, lighter rods may be the way to go, but for endurance and reliability in high-stress environments, steel rods could prove more advantageous. Always analyze the engine's intended use to make the best choice for connecting rod materials and designs.