+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the ever-evolving world of equipment maintenance, selecting the right Cylinder Seal Kits is crucial for ensuring optimal performance and longevity of machinery. Industry expert, John Smith, a renowned technician with over two decades of experience, emphasizes the significance of choosing quality seals by stating, "The right seal kit not only enhances efficiency but also prevents costly downtimes." As machines operate under high pressures and variable temperatures, the integrity of seal kits directly impacts functionality and reliability.

Understanding the various factors involved in selecting Cylinder Seal Kits is essential for equipment operators and maintenance personnel alike. Different applications require different materials and designs, which can significantly affect seal performance and lifespan. This article will guide you through critical considerations that will help you make informed decisions when selecting the right seal kits for your specific equipment needs. From assessing compatibility to evaluating material properties, we will explore the essential elements that contribute to effective sealing solutions in a variety of operational environments.

Cylinder seal kits are crucial components in various machinery, serving as the barrier between hydraulic fluid and unwanted contaminants. Understanding their functionality is essential for maintaining optimal equipment performance. These kits typically include seals, O-rings, and other sealing elements that prevent leaks, ensuring that a machine operates smoothly and efficiently. By maintaining pressure within the system, they help in enhancing the equipment's durability and reducing the risk of breakdowns caused by fluid loss or contamination.

Selecting the right cylinder seal kit involves considering factors such as the type of fluid used, temperature ranges, and specific application requirements. Different materials offer varying resistance to chemical exposure and temperature fluctuations.

For instance, nitrile rubber is often suitable for oil-based fluids, while fluorocarbon seals may be necessary for higher temperature applications. Understanding these materials and their applications can significantly impact the longevity of the equipment. Proper installation and regular maintenance of these seal kits are also vital to ensure they function effectively, safeguarding against premature wear and maintaining system integrity.

When it comes to selecting the right cylinder seal kits for your equipment, compatibility is of the utmost importance. Each piece of equipment is designed to operate with specific types of seals that can significantly affect performance and longevity. Therefore, before making a purchase, it’s essential to closely evaluate the equipment model you are working with. Cross-referencing the seal specifications provided by the manufacturer against the compatibility of seal kits ensures you avoid issues related to improper fitting, leakages, and reduced operational efficiency.

Tips to ensure compatibility include checking the dimension specifications of both the cylinder and the seal kit. Measure the bore, rod, and gland diameters to confirm that the seal kit matches your equipment's requirements. Additionally, take note of the material composition of the seals, as these materials can play a significant role in their effectiveness under various temperatures and pressures.

It’s also advisable to consult your equipment manual or a professional concerning the seal kits that are recommended for your specific model. This proactive approach helps in identifying any unique features that your equipment may have, ensuring the selected seal kit will perform optimally and enhance overall performance.

This chart illustrates the compatibility evaluation of various cylinder seal kits with different equipment models, aiding in the selection process.

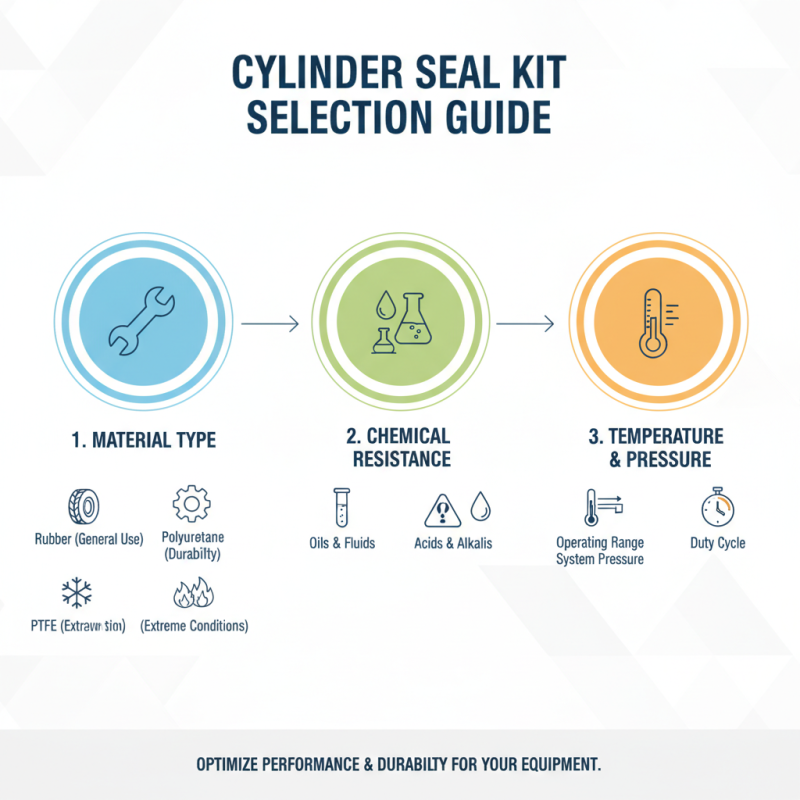

When selecting the right cylinder seal kits for your equipment, it is essential to consider several key factors that can significantly influence performance and durability. First, the type of material used in the seal kit plays a crucial role. Different materials offer varying levels of resistance to chemicals, temperature, and wear, which affects their longevity and effectiveness in diverse operational environments. For instance, rubber seals may be ideal for general use, while more robust alternatives like polyurethane or PTFE are better suited for extreme conditions.

Another important factor to consider is the compatibility of the seal kit with your specific equipment model. This involves not only fitting dimensions but also understanding the operational requirements of the machinery. Ensure that the seals are designed to withstand the pressure and temperature fluctuations that your equipment experiences.

**Tips:** Always refer to the manufacturer’s specifications to ensure you are choosing the correct size and type of seal kit. Additionally, it's advisable to consult with a professional if you are uncertain about the best materials or designs for your specific applications. Regular maintenance checks on the seals can also extend their life and prevent unexpected failures, thereby enhancing the overall efficiency of your equipment.

When selecting cylinder seal kits for your equipment, the material types used in their construction significantly influence both performance and durability. Typically, seal kits are crafted from materials such as nitrile rubber, polyurethane, and fluorocarbon, each offering distinct advantages and potential limitations. Nitrile rubber, known for its excellent resistance to oil and abrasion, is often the preferred choice for applications involving hydraulic fluids. However, while it performs well in moderate temperature ranges, it may not endure exposure to extreme heat or certain chemicals.

On the other hand, polyurethane seals are recognized for their superior resilience and wear resistance, making them ideal for high-pressure hydraulic systems. Their ability to maintain elasticity over a broader temperature spectrum enhances their durability in dynamic applications. Meanwhile, fluorocarbon seals provide exceptional chemical resistance, making them suitable for harsh environments where other materials might fail. Understanding these material properties allows users to select the appropriate cylinder seal kit that aligns with the specific demands of their equipment, ensuring optimal performance and longevity in operation.

| Material Type | Key Properties | Temperature Range (°C) | Chemical Resistance | Typical Applications |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | Great elasticity, good tensile strength | -40 to 100 | Oil and fuel resistant | Automotive, hydraulic systems |

| Polyurethane (PU) | Excellent wear resistance, high tensile strength | -30 to 80 | Good resistance to oils and solvents | Industrial machinery, pumps |

| Fluorocarbon (FKM) | Superior heat and chemical resistance | -20 to 200 | Excellent resistance to fuels and acids | Aerospace, chemical processing |

| Silicone | Good flexibility, excellent high-temperature performance | -50 to 200 | Limited oil resistance | Food processing, medical devices |

| PTFE | Non-stick, excellent chemical resistance | -200 to 260 | Resistant to most chemicals | High-performance applications |

When installing cylinder seal kits, thorough preparation is key to a successful outcome. First, ensure that all necessary tools and materials are on hand, including appropriate seals, lubricants, and cleaning supplies. Before installation, clean the cylinder and surrounding areas to remove any debris or contaminants. This careful preparation reduces the risk of damage to the seals and guarantees a proper fit. Additionally, it’s essential to inspect the cylinder for wear or damage, as this can affect the performance of the seal kits.

During the installation process, follow the manufacturer’s guidelines meticulously to avoid any misalignment. Apply lubrication to the seals to facilitate easier installation and to prevent potential tearing. It is crucial to ensure that seals are seated correctly to avoid leaks. After installation, conduct a thorough inspection to verify that everything is installed properly. Regularly checking for signs of wear or leakage after use will help maintain the integrity of the cylinder seal kits. Implementing a routine maintenance schedule can significantly extend the life of your equipment and enhance overall performance.