+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

When it comes to optimizing engine performance, choosing the right cylinder liner is a critical decision for any mechanic or vehicle owner. The cylinder liner plays a vital role in the engine's overall functionality, serving as a protective layer between the combustion chamber and the engine block, while ensuring proper sealing and thermal management. Selecting the appropriate cylinder liner involves understanding various factors, including material composition, dimensions, and compatibility with the specific engine model.

In the following sections, we will delve into the essential aspects to consider when making this important choice. From assessing the specific requirements of your engine to evaluating the benefits of different cylinder liner materials, this guide aims to equip you with the knowledge necessary for making an informed decision. By carefully considering these elements, you can enhance your engine's efficiency, longevity, and performance, ultimately leading to a smoother driving experience.

Understanding Cylinder Liners and Their Role in Engine Performance

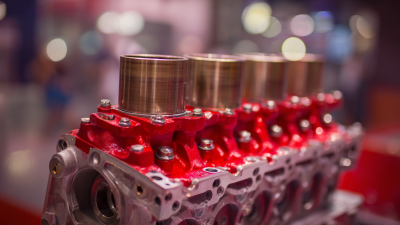

Cylinder liners play a crucial role in the overall performance and longevity of an engine. These components act as a protective barrier between the engine block and the combustion process, helping to contain the heat and pressure generated during operation. By providing a smooth surface for the piston to move against, cylinder liners enhance friction reduction, ultimately improving the efficiency and power output of the engine. Thus, selecting the right type of cylinder liner is paramount for achieving optimal engine performance.

When choosing cylinder liners, it’s essential to consider factors such as material composition, thickness, and design. Different materials like cast iron or steel can offer varying degrees of durability and heat resistance, while the thickness of the liner can influence heat dissipation and the overall weight of the engine. Understanding these aspects is vital when making a selection, as they can significantly impact engine performance and maintenance requirements.

Tips: Always consult your engine specifications to determine the appropriate liner size and type required for your engine model. Additionally, consider the operating conditions of your engine; for high-performance applications, opting for liners with superior thermal conductivity might be beneficial. Regularly inspecting and maintaining your cylinder liners can also prolong their life, ensuring consistent engine performance.

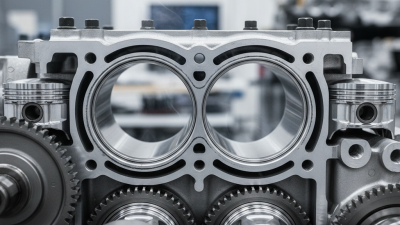

When selecting the right cylinder liner for your engine, it's essential to understand the various types available on the market. The most common types include wet liners and dry liners. Wet liners are designed to be in direct contact with the coolant, providing superior heat dissipation. Their construction usually involves a thicker wall that allows for excellent heat transfer, making them ideal for high-performance engines or applications where temperature management is crucial. Moreover, wet liners offer the advantage of easier replacement without requiring complete engine teardown.

On the other hand, dry liners are fitted directly into the engine block and do not contact coolant. They tend to be more rigid and provide a robust solution for many engine applications. Dry liners are often favored for their durability and stability, as they help maintain proper cylinder dimensions under operating pressures. Additionally, they are lightweight, allowing for better efficiency in certain engine designs. When choosing between these two types, it's important to consider factors like the intended application, the operating conditions of the engine, and the specific heat management requirements to ensure optimal performance and longevity.

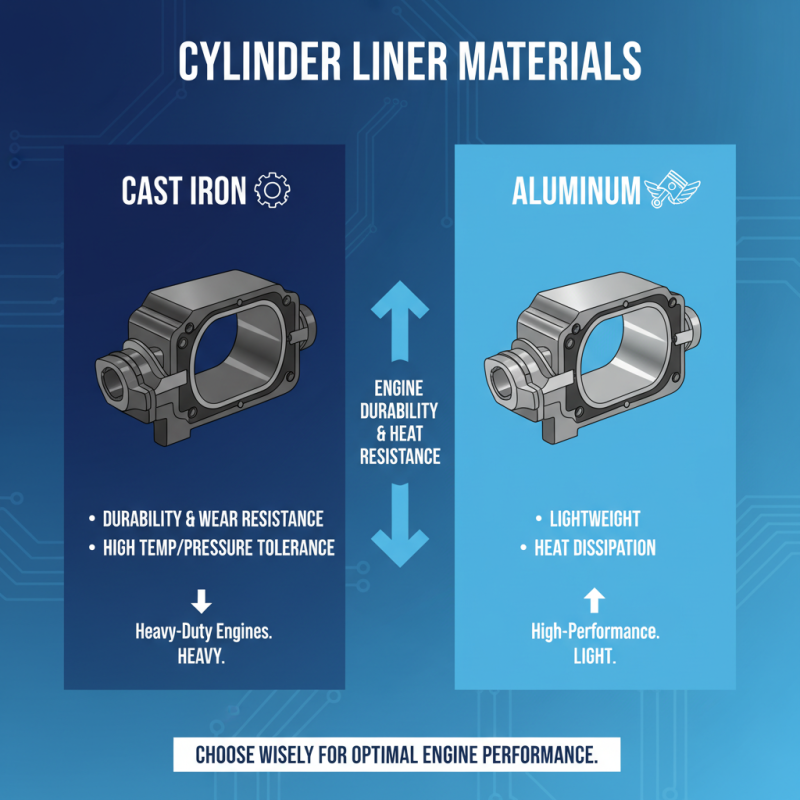

When selecting a cylinder liner, one of the key factors to consider is the material, as it directly impacts the durability and heat resistance of the engine. Common materials include cast iron and aluminum, each offering distinct advantages. Cast iron liners are known for their excellent wear resistance and durability, making them a popular choice for heavy-duty engines. They can withstand high pressures and temperatures, contributing to the engine's longevity. However, the weight of cast iron can be a disadvantage in high-performance applications where reducing overall engine weight is critical.

On the other hand, aluminum cylinder liners are increasingly favored in modern engine designs, particularly for their lightweight properties and good thermal conductivity. This allows for better heat dissipation, which is crucial in high-performance scenarios. Aluminum liners can also be treated to enhance their hardness and resistance to wear, ensuring they can withstand the rigors of demanding applications. Ultimately, evaluating these material options based on the specific requirements of your engine will help determine the best choice for optimal performance and reliability.

When selecting a cylinder liner, it is crucial to assess its compatibility with your specific engine specifications and design. The suitability of the cylinder liner directly affects engine performance, durability, and efficiency. According to the International Council on Combustion Engines, around 30% of engine failures are attributed to improper liner selection. This statistic underscores the importance of aligning material choices and dimensions with the intended engine use and operational conditions.

Engineers must consider various aspects such as cylinder diameter, wall thickness, and material composition when evaluating potential liners. For instance, a study published by the Society of Automotive Engineers indicates that integrating liners made from advanced materials like ductile iron or high-silicon aluminum can enhance thermal conductivity and reduce wear, thereby promoting better performance in high-stress environments. Moreover, many current designs also factor in thermal expansion characteristics to ensure minimal distortion during operation, which can be critical for maintaining optimal sealing and compression ratios.

Additionally, understanding the engine’s load requirements and operating speeds is essential. Research suggests that liners designed for high-performance engines often require tighter tolerances and more robust material properties to withstand higher thermal and mechanical stresses. The right choice in cylinder liner not only optimizes performance but also extends the service life of the engine, reducing maintenance costs and enhancing overall reliability.

When selecting the appropriate cylinder liner for your engine, one of the most critical aspects to consider is the long-term maintenance costs associated with different materials and designs. Cylinder liners are subjected to extreme conditions, including high temperatures and pressures, which can lead to wear and damage over time. By opting for a higher quality liner, you may incur a higher initial cost, but this investment often translates into lower maintenance expenditures in the future. Durable materials like cast iron or advanced composite options may resist wear and corrosion better, reducing the frequency of necessary replacements and repairs.

Additionally, understanding the engine's specific requirements and the operating environment can significantly influence maintenance needs. For instance, engines operating in harsh conditions may benefit more from robust liners that can withstand greater stress. Evaluating the compatibility of the liner with your engine's design is essential, as a mismatch can lead to inefficiencies and increased operational costs. Regular maintenance checks must be factored in, emphasizing that proactive care can prevent costly failures down the line. By thoroughly assessing both upfront costs and potential long-term maintenance, you can make an informed decision that suits your needs and ensures optimal engine performance.