+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the construction and demolition industries, the choice of tools can significantly impact the efficiency and effectiveness of a project. Among the tools available, the Breaking Hammer stands out as a vital instrument for various applications, ranging from concrete demolition to road repair. According to the latest industry reports, in 2022, the global demand for breaking hammers reached approximately $1.5 billion, reflecting a 7% annual growth rate, driven by an increasing number of infrastructure projects worldwide. This growth signifies not only the importance of breaking hammers but also the need for professionals to select the right tool for specific tasks.

Selecting the correct Breaking Hammer involves considering factors such as weight, impact energy, and intended use. Studies have shown that the appropriate weight can enhance productivity while reducing operator fatigue, as tools that are too heavy can hinder performance on job sites. Additionally, modern advancements in breaking hammer technology have led to the development of models that offer improved vibration control and energy efficiency. As contractors and construction professionals aim to optimize their workflows, understanding the nuances of breaking hammers will be essential for achieving successful project outcomes.

When selecting the right breaking hammer for your project, understanding the specific requirements based on size and material is crucial. First, consider the dimensions of the area or item you’ll be working on. For larger demolition tasks, a heavier hammer with a longer handle can provide the necessary leverage and impact force to break through concrete or rock. Conversely, for smaller projects, a lighter hammer is more manageable and allows for precision without excessive strain.

Additionally, the type of material you are working with should influence your choice of hammer. Different materials require different hammering techniques and force levels. For instance, softer materials like brick may only need a moderate impact to break apart, while harder substances like reinforced concrete necessitate a more robust hammer with a greater striking power. Understanding these factors will help you select a breaking hammer that not only fits your physical requirements but also enhances your efficiency and effectiveness in your demolition tasks.

When selecting a breaking hammer for your project, it’s crucial to understand the different types available and their specific uses. Breaking hammers are primarily designed for demolition and construction tasks, and they come in various styles suited for different materials and applications. For instance, pneumatic breaking hammers are powered by compressed air, making them ideal for breaking up concrete or rocky surfaces. Their intensity allows for efficient work when dealing with large-scale demolition projects.

On the other hand, electric breaking hammers offer a more convenient option for lighter tasks. They are generally easier to operate and require less setup than their pneumatic counterparts, making them suitable for smaller jobs, such as removing tiles or breaking asphalt. Additionally, manual breaking hammers are available, which are perfect for precision tasks where control and finesse are crucial.

Regardless of the type, understanding the power source, weight, and striking force is essential for selecting the right hammer to match the demands of your specific project.

When selecting a breaking hammer for your next project, understanding the impact of weight and impact energy is crucial for optimal performance. The weight of a breaking hammer directly influences its effectiveness; heavier hammers often deliver greater force, allowing for the breaking of tougher materials. However, a balance must be struck, as excessive weight can lead to user fatigue and decreased precision. Therefore, assessing the specific requirements of your project and choosing a hammer that fits your physical capabilities while still being able to accomplish the task at hand is essential.

Impact energy, measured in joules or foot-pounds, is another vital factor in your decision-making process. It reflects the hammer's ability to deliver a powerful blow to the target material. A hammer with higher impact energy tends to break through materials more efficiently, making it suitable for heavy-duty demolition tasks. However, for finer work, such as breaking concrete in detailed areas, a hammer with moderate impact energy can provide better control and finesse. Ultimately, evaluating both the weight and impact energy of a breaking hammer will ensure that you select the right tool that not only meets the demands of your project but also enhances your working experience.

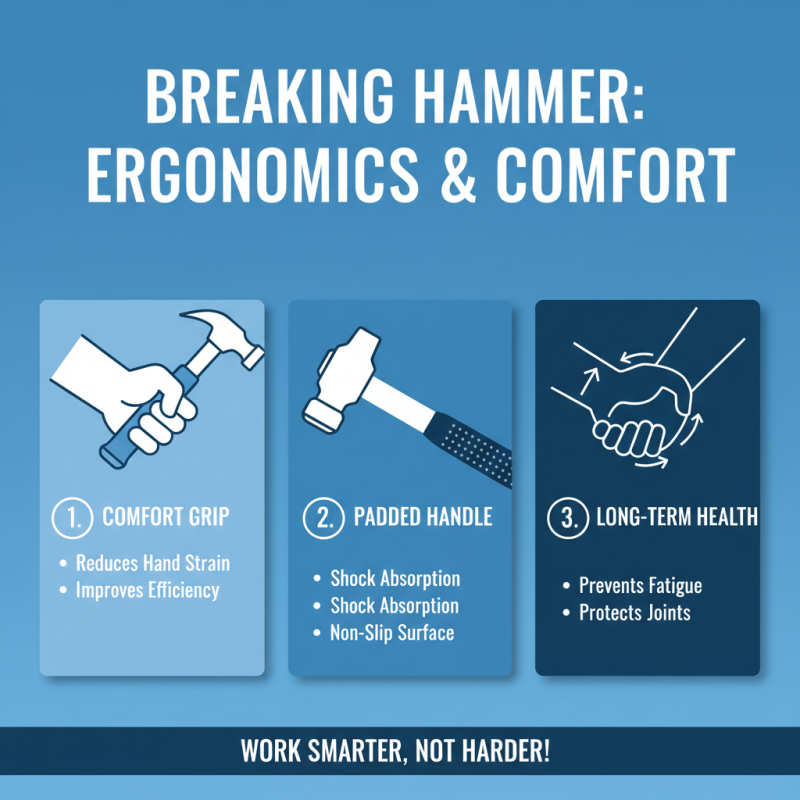

When selecting a breaking hammer for your next project, one of the most crucial factors to consider is ergonomics and user comfort. A hammer that feels good in your hand can significantly influence not only the efficiency of your work but also your long-term health. Look for hammer designs that feature comfortable grips, as this will help reduce strain on your hands and wrists. A rubberized or padded handle can provide a non-slip surface and absorb some of the shock during impactful strikes, making repetitive tasks far less taxing.

Additionally, the weight and balance of the hammer should not be overlooked. A well-balanced hammer allows for better control and precision in your work, minimizing fatigue during extended use. Models that distribute weight evenly across the handle can enhance user comfort, making it easier to manage heavy tasks without compromising technique. Ensure that the chosen hammer aligns with your physical capabilities, and don’t hesitate to test different options to find what feels most comfortable. Prioritizing ergonomics will not only improve your productivity but also contribute to a safer and more pleasant working experience.

When it comes to selecting a breaking hammer for your next project, understanding the balance between cost and quality is crucial. While it might be tempting to choose the cheapest option available, it's essential to consider the long-term impact on your work and the overall value the tool brings to your project. Investing in a quality hammer can save you money in the long run by reducing the need for frequent replacements and ensuring consistent performance.

Tips: Before making a purchase, assess the specific needs of your project and the expected frequency of use. If you plan to use the breaking hammer regularly or for heavy-duty tasks, prioritize quality features such as durability and ergonomic design. Additionally, think about your budget. Set a realistic price range that allows for quality without breaking the bank—remember that a higher initial cost can lead to greater efficiency and fewer repairs.

When comparing options, look for user reviews and seek recommendations from specialists to help gauge the performance and reliability of the tools you consider. Keep in mind that the total cost includes not only the purchase price but also accessory items like bits or safety gear that might enhance your project's outcome. By carefully weighing cost against quality, you can make an informed decision that suits your needs and budget.