+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Choosing the right cylinder liner is crucial for optimizing engine performance and longevity. As the automotive industry continues to advance, with the global market projected to reach a valuation of over $5 trillion by 2028, the significance of high-quality components like cylinder liners cannot be overstated. According to a report by MarketsandMarkets, the engine components market is expected to grow at a CAGR of 4.6% from 2021 to 2026, emphasizing the increasing demand for robust engine parts that can withstand higher pressures and temperatures.

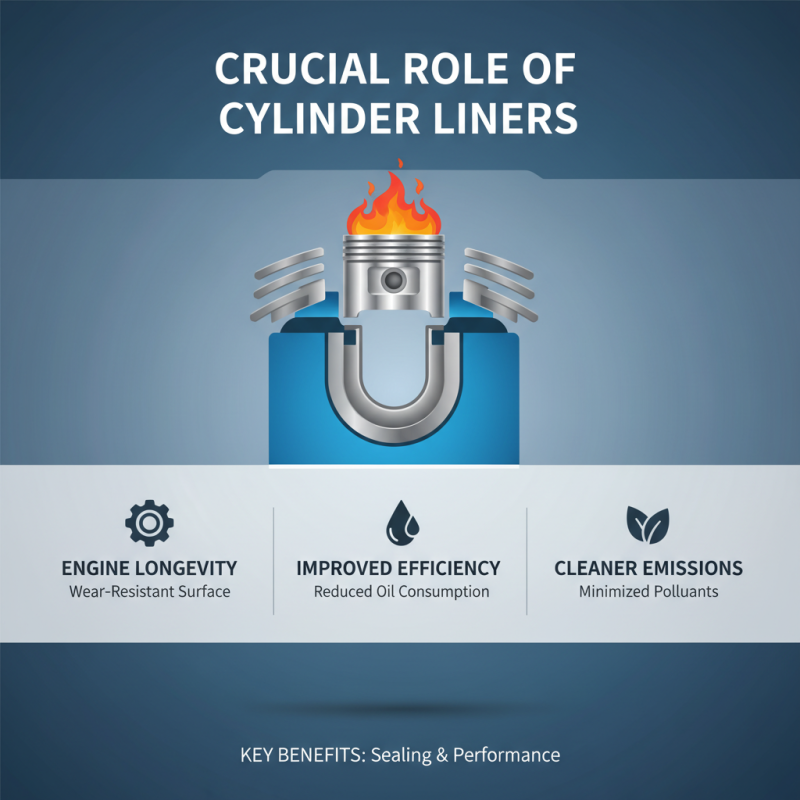

Cylinder liners play a vital role in maintaining engine efficiency by providing a wear-resistant surface for the piston rings, reducing friction, and enhancing the overall durability of the engine. A well-selected cylinder liner can lead to improved fuel efficiency, lower emissions, and extended engine lifespan. Industry reports indicate that improper selection can lead to significant performance issues and costly repairs. Therefore, understanding the various types of cylinder liners, such as cast iron and aluminum, and their specific applications is essential for any engine builder or technician aiming to achieve optimal performance and reliability.

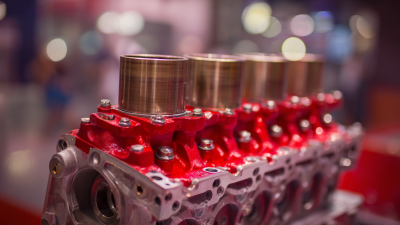

Cylinder liners play a crucial role in the overall performance of an engine, acting as a protective sleeve that lines the engine block and interfaces with the pistons. Their primary function is to provide a wear-resistant surface that can withstand the intense friction and heat generated during combustion. By doing so, cylinder liners help ensure the longevity of the engine components and improve overall efficiency. A well-chosen cylinder liner improves sealing, reduces oil consumption, and minimizes emissions, contributing to a cleaner environment and better performance.

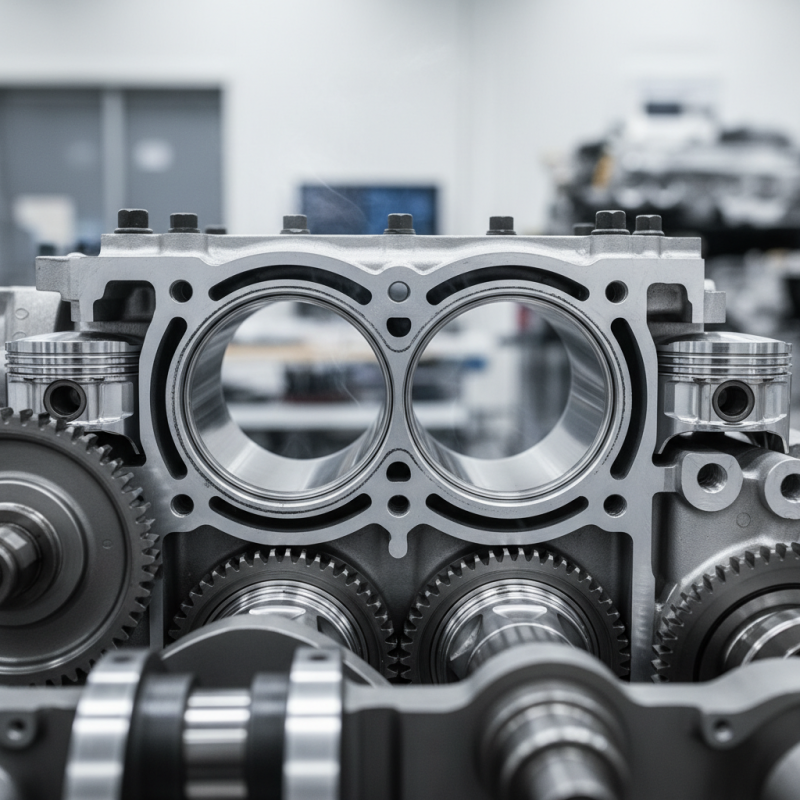

Selecting the appropriate cylinder liner involves considering several factors, including the material composition, thickness, and design. Different engines have varying operational demands, which means the liner must be tailored to match these specifications. For instance, a performance engine may require a liner that offers higher thermal stability and strength, while a standard engine might prioritize cost-effectiveness and reliability. Additionally, understanding the role of coolant flow and thermal expansion in the overall design is vital, as these elements can greatly influence engine performance and durability. Thus, making an informed choice on cylinder liners is key to optimizing engine function and ensuring dependable operation.

When it comes to selecting the right cylinder liner for your engine, understanding the two primary types—cast iron and steel—is crucial. Cast iron liners are widely recognized for their durability and excellent wear resistance. They are often preferred in standard applications, particularly in automotive and heavy-duty engines. The material's ability to withstand high temperatures and pressures makes it suitable for a variety of environments. Additionally, cast iron has inherent characteristics that help in maintaining a good seal and reducing oil consumption, making it a reliable choice for many engine designs.

On the other hand, steel cylinder liners are becoming increasingly popular, especially in high-performance and racing applications. Steel offers a higher strength-to-weight ratio compared to cast iron, which can result in a lighter engine block. This type of liner excels in high-stress conditions as it can better accommodate thermal expansion and contraction. Furthermore, steel liners are often treated with advanced coatings to enhance their hardness and resistance to corrosion. As a result, they are ideal for engines that require precise tolerances and heightened performance, catering to enthusiasts who prioritize speed and efficiency. Each type of liner has distinct advantages and applications, making it essential to evaluate your engine's specific needs before making a decision.

| Cylinder Liner Type | Material | Applications | Pros | Cons |

|---|---|---|---|---|

| Dry Cylinder Liner | Cast Iron | Automotive Engines | Cost-effective, good wear resistance | Heavier, less corrosion resistance |

| Wet Cylinder Liner | Cast Iron | Heavy-Duty Diesel Engines | Better cooling, easier replacement | Potential for rust and corrosion |

| Sleeved Cylinder Liner | Steel | High-Performance Engines | Improved strength, lighter | More expensive, complex installation |

| Linerless Cylinder Block | Aluminum Alloy | Modern Lightweight Engines | Weight savings, excellent thermal efficiency | Higher production costs, potential for wear over time |

When selecting the right cylinder liner for your engine, there are several key factors to consider that can significantly impact performance and longevity. One crucial aspect is the material composition of the liner. Typically, cylinder liners are made from cast iron, which offers high wear resistance and thermal stability. According to a 2021 industry report by MarketsandMarkets, the demand for advanced materials in engine components is accelerating, with a projected growth rate of 5.2% annually, highlighting the importance of selecting the right materials for improved efficiency and durability.

Another factor to consider is the liner design, which includes characteristics such as surface finish and wall thickness. A smoother surface can reduce friction, leading to better fuel efficiency, while thicker walls can enhance strength and heat retention. Research indicates that engines with optimized liner designs can achieve up to a 10-15% increase in thermal efficiency, crucial for high-performance applications.

**Tip:** When evaluating cylinder liners, it's advisable to assess the specific engine application and the expected operating conditions. Understanding the demands placed on the engine can help you choose a liner that not only meets the basic requirements but also enhances overall performance.

**Tip:** Additionally, consider the compatibility of the cylinder liner with other engine components. This includes assessing how the liner interacts with piston materials and lubrication systems, as a mismatched setup can lead to premature wear or failure, ultimately affecting the engine's operational lifespan.

When selecting a cylinder liner for your engine, it is crucial to align your choice with your engine's specifications and performance goals. Compatibility with the engine’s design and operating conditions can significantly impact performance and longevity. For instance, a study conducted by the Society of Automotive Engineers (SAE) suggests that engines using liners optimized for specific bore sizes and materials can achieve a thermal efficiency increase of up to 10%. This efficiency gain is often attributed to enhanced heat dissipation and reduced friction, highlighting the importance of precise compatibility in your selection process.

Additionally, performance goals should dictate the type of liner material you choose. Engineered materials such as cast iron and aluminum alloys have their distinct advantages; for example, aluminum liners are known for their lower weight, which improves engine responsiveness and fuel efficiency. According to a report by the Engine Builders Association, engines equipped with lightweight aluminum liners demonstrated a horsepower increase of 5% under competitive conditions compared to traditional options. Therefore, understanding these dynamics and conducting a thorough analysis of your engine's compatibility with various liner materials can lead to more effective performance outcomes.

Maintaining cylinder liners is crucial for ensuring optimal engine performance and longevity. Regular inspections can help identify wear and tear early, allowing for timely interventions before more significant damage occurs. It’s important to check for signs of scoring or pitting, which can indicate improper lubrication or contamination. Keeping the engine’s oil at the correct level and replacing it at recommended intervals will also mitigate wear on the cylinder liners.

Another key maintenance tip is to use high-quality coolant. Overheating can lead to warping and degradation of the cylinder liners, so monitoring the cooling system is essential. Additionally, ensuring that the engine is properly tuned and calibrated can reduce excess pressure and temperatures, further protecting the cylinder liners. Implementing a routine maintenance schedule that includes these checks and balances can help extend the lifespan of your cylinder liners, ultimately contributing to a smoother and more efficient engine operation.