+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Choosing the right Arm Cylinder is a crucial step in your project. The hydraulic system industry has seen significant growth. Reports from the International Federation of Robotics indicate that the demand for hydraulic cylinders is expected to rise by 5% annually through 2025. Selecting the correct Arm Cylinder can enhance efficiency and performance considerably.

Understanding the specifications and applications of Arm Cylinders is essential. Various types serve different functions. Specifications like stroke length, bore size, and pressure ratings impact performance. Incorrect choices can lead to failures and increased downtime. The realization of this can be challenging yet pivotal for project success.

Many engineers face difficulties when selecting Arm Cylinders. Misjudgments often stem from a lack of comprehensive data. It’s vital to analyze the specific requirements of your application. Not considering environmental factors or load requirements could result in unfavorable outcomes. Reflecting on these aspects will support more informed decisions.

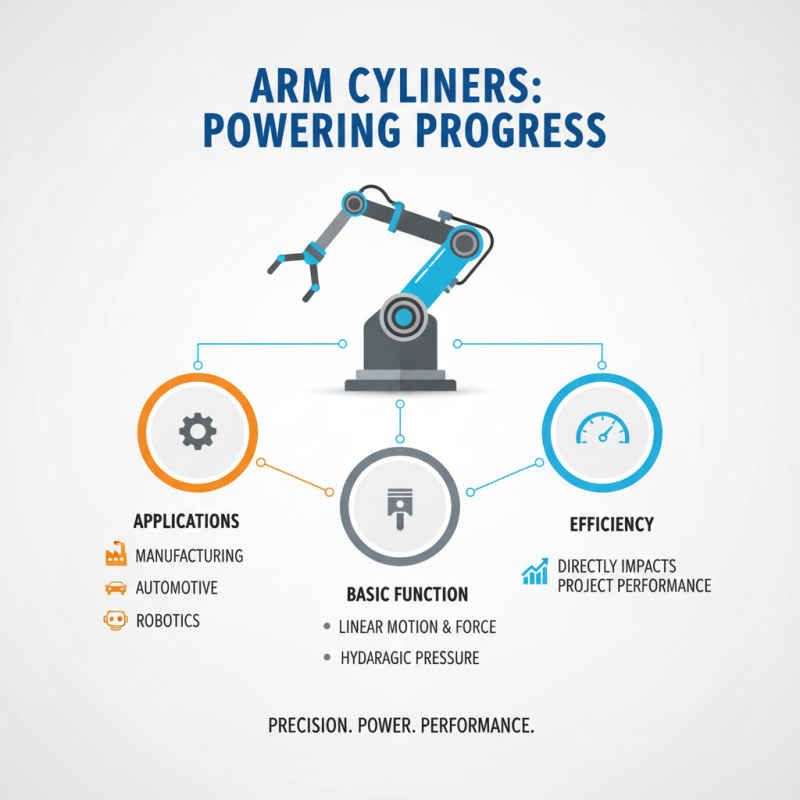

Arm cylinders play a crucial role in various applications. They are essential in industries such as manufacturing, automotive, and robotics. Understanding their basic functions can help in selecting the right one for your project. These cylinders typically provide linear motion and force. Many rely on the pressure of hydraulic fluid to operate. Their efficiency directly impacts project performance.

Choosing the right arm cylinder involves assessing your specific needs. Consider the load capacity required and the working environment. Will it face high temperatures or corrosive substances? These factors can greatly affect the material choice for the cylinder. Also, look at the cylinder's stroke length. It must accommodate the range of motion needed for your tasks.

However, selecting an arm cylinder is not always straightforward. There might be unexpected challenges during installation or operation. Sometimes, a cylinder may not perform as anticipated. It's vital to reflect on these issues and adapt accordingly. Asking for feedback can guide your decision-making. Engaging with experts can offer valuable insights into cylinder performance.

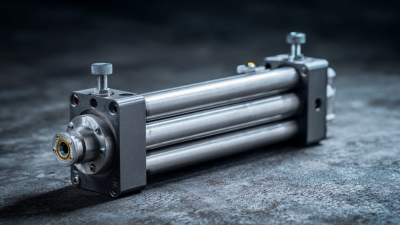

When selecting an arm cylinder, size and stroke length are critical. The size must match your system’s requirements. A cylinder that is too large could lead to inefficiency. On the other hand, a small cylinder may not provide adequate power. It’s essential to assess your project's needs carefully. Are the forces and loads manageable with the chosen size? Consider these factors.

Stroke length is equally important. This determines how far the cylinder can extend. A short stroke might limit motion, while a long stroke could waste space. Think about the range of motion your project demands. Do you need full extension or just part of it? Measure the distance accurately to avoid surprises later.

Tips: Always calculate the maximum load. Test your choices with prototypes before finalizing. This helps uncover potential issues early on. Don’t rush the decision; revisit your options frequently. Reflection is key in ensuring you've chosen the best fit.

| Parameter | Recommended Value | Notes |

|---|---|---|

| Cylinder Size | 1.5 in - 10 in | Choose based on load requirements. |

| Stroke Length | 4 in - 36 in | Must match the application reach. |

| Operating Pressure | 1000 psi - 3000 psi | Higher pressure can provide more power. |

| Material | Steel, Aluminum | Depends on environment and load. |

| Mounting Style | Fixed, Pivot, or Rod End | Choose based on the mechanism. |

When selecting an arm cylinder, evaluating pressure ratings is crucial. A cylinder must withstand the pressure it encounters during operation. This is often based on the design and intended use. For instance, if a project requires high pressure, a cylinder rated for that specification is essential. However, exceeding these ratings can lead to failures.

Consider the material of the cylinder as well. Different materials respond differently to pressure. Steel cylinders may perform better in high-pressure situations than aluminum counterparts. Yet, aluminum is lighter, which could be beneficial in some projects. Balancing durability and weight can be challenging.

Moreover, unforeseen factors can impact performance. Temperature changes, for instance, can alter pressure dynamics. A cylinder might perform well under specific conditions but fail when the environment changes. It’s crucial to think about these variables. Each project presents unique challenges. Reflecting on potential issues could save time and resources. Choosing the right cylinder demands careful analysis and sometimes a bit of trial and error.

When selecting an arm cylinder for your project, material selection is critical. The environment where the cylinder operates can significantly impact its performance and lifespan. For instance, data from the Fluid Power Journal indicates that nearly 30% of hydraulic failures are attributed to corrosion and environmental wear. Thus, choosing the right material is essential to avoid costly replacements.

For outdoor applications, materials such as stainless steel or specialized coatings can offer better protection against the elements. Aluminum may be a lightweight option, but it generally lacks durability in harsh conditions. According to a study by the International Journal of Hydraulics, nearly 40% of operators reported premature failure due to inadequate material choice in abrasive environments.

Industries often overlook maintenance needs associated with material degradation. For instance, regular inspections can catch surface damage before it leads to malfunction. Ignoring these aspects can lead to extended downtimes and increased costs. Hence, being proactive in selecting and maintaining the right construction material can make a substantial difference in project success.

Maintaining arm cylinders is crucial for their longevity. Regular inspections help identify wear and tear. Look for leaks or unusual noises. These are signs they need attention. Clean the cylinders regularly to remove dirt and debris. Neglecting this can lead to premature failures.

It’s important to follow manufacturer guidelines for lubrication. Using the wrong lubricant can cause issues. Many overlook this and face costly repairs later. Ensure seals are in good condition to prevent fluid loss. Check them frequently, as a small crack can lead to bigger problems.

Documenting maintenance activities can help in tracking performance. Note any changes observed during inspections. This could prevent future malfunctions. Remember, a little attention now can save time and money later. Regular maintenance ensures the arm cylinder works effectively.

This bar chart illustrates the relative importance of various maintenance considerations for ensuring the longevity and reliability of arm cylinders. Each factor is rated on a scale from 1 to 10 based on its impact on performance.