+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

When tackling soil compaction, the selection of the right equipment is crucial. A Vibrating Compactor Rammer stands out as an efficient tool. It effectively compacts soil, asphalt, and other materials with ease. This machine uses vibration to enhance soil density and stability.

Choosing the best Vibrating Compactor Rammer involves understanding your project's specific needs. Different models offer varying features and capabilities. It is essential to consider the terrain and soil type before making a decision. Sometimes, what seems perfect on paper may not perform as expected in real-world conditions.

Investing in a top-quality Vibrating Compactor Rammer can significantly impact your project's efficiency. A well-chosen rammer can speed up the process while ensuring durability. However, understanding the limitations of the rammer is equally important. Reflecting on your choices can lead to better outcomes in future projects.

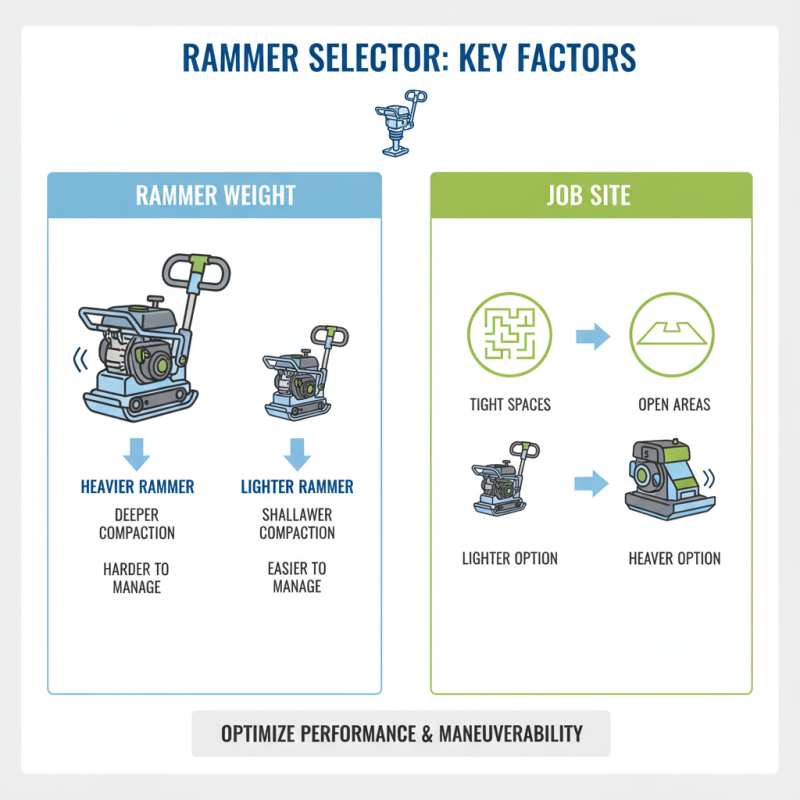

When selecting a vibrating compactor rammer, consider key factors that can greatly impact performance. The weight of the rammer affects how well it compacts soil. Heavier rammers provide deeper compaction. However, they can be harder to maneuver. If the job site is tight, a lighter option might be more practical.

Another aspect is the frequency of vibration. A higher frequency generally leads to faster compaction. Yet, excessive vibration can disturb surrounding areas. Balance is crucial. Look for models that offer adjustable settings. This flexibility allows you to adapt to various soil types. Additionally, check the base plate size. Wider plates cover more area, but can be less effective in tight spots.

Consider ease of use and maintenance as well. Some machines are more complex than they need to be. This can lead to frustration and errors during operation. User-friendly designs save time and effort. Also, factor in the noise levels. Vibrating rammers can be loud, prompting potential issues with local regulations. Be mindful of surroundings to mitigate disruptions.

Vibrating compactor rammers are essential for effective soil compaction. There are several types of these machines, each designed for specific applications. The most common rammers are mechanical and electric. Mechanical rammers work well on larger projects, while electric ones are quieter and ideal for urban areas.

Different rammers serve unique purposes. For example, light-duty rammers are great for small jobs like landscaping. They can efficiently compact soil around flower beds. Heavy-duty rammers tackle tougher materials, such as gravel or clay, often used in road construction. Proper selection of a rammer is essential for achieving desired compaction results.

However, not all rammers perform equally in every situation. Soil conditions can vary significantly; some rammers may struggle with certain types of soil. Inspecting the machine beforehand matters. Regular maintenance can prevent breakdowns, but some users overlook this step. An improperly maintained rammer can lead to inefficiencies and costly delays. Understanding the applications ensures better performance and project success.

When selecting a vibrating compactor rammer, efficiency is key. An efficient rammer can compact soil to a density of 90% or more, often required for stable construction sites. According to industry data, proper compaction can reduce soil settlement and improve load-bearing capacity by up to 50%. The capabilities of these tools significantly impact project timelines and costs.

Key features to consider include weight, engine power, and vibration frequency. A heavier rammer exerts more force, achieving better compaction. A typical weight falls between 70 to 200 pounds. An engine power of 4 to 8 HP is standard, providing the necessary thrust for tough jobs. Additionally, a vibration frequency of 4000 to 6000 vibrations per minute often yields optimal results.

**Tip:** Choose a rammer with adjustable settings for different soil types. This flexibility can enhance efficiency on varied jobs.

Another aspect is maintenance. Regular checks on oil levels and filters can prolong a rammer's lifespan. Neglecting these can lead to inefficient compaction and potential breakdowns.

**Tip:** Keep a maintenance log to track performance and repairs. This practice can reveal patterns and prevent costly delays in the future.

To maintain a vibrating compactor rammer, you must focus on a few key areas. Regular cleaning after each use is essential. Soil and debris can accumulate on the base and parts, negatively affecting performance. Inspect the rammer for signs of wear, especially on the base plate and rubber feet. If you see significant damage, consider replacing these parts promptly.

Lubrication plays a vital role in ensuring smooth operation. Check the manufacturer's guidelines for the right lubricant. Apply it to moving parts to reduce friction. However, avoid over-lubricating, as that can attract more dirt and debris. Pay attention to the engine oil level if your rammer has an engine. It’s crucial to change the oil according to the suggested schedule.

Moreover, vibration issues may arise if not adjusted correctly. Sometimes, operators notice uneven compaction due to improper settings. Reflect on your working technique. Evaluate whether you’re applying constant pressure. It’s easy to overlook small aspects that lead to significant performance drops. Regularly reassess your methods to keep your compactor rammer in top condition.

| Model | Weight (lbs) | Engine Type | Compaction Depth (inches) | Fuel Efficiency (gallons/hour) | Maintenance Frequency (hours) |

|---|---|---|---|---|---|

| VCR-70 | 70 | Gas | 12 | 0.6 | 50 |

| R-900 | 90 | Electric | 15 | 0.4 | 40 |

| PB-65 | 65 | Gas | 10 | 0.5 | 60 |

| XRS-80 | 80 | Diesel | 14 | 0.7 | 55 |

| CZ-72 | 72 | Gas | 11 | 0.55 | 45 |

Choosing the right vibrating compactor rammer can enhance soil compaction efficiency. Many models and brands are available in the market. Each has unique features suited for different projects. Understanding these features helps in making an informed decision.

When selecting a rammer, consider the weight and size. Heavier models provide more force, while lighter ones are easier to handle. Look for rammers with adjustable settings. This allows for customization based on the soil type. Some models can be too heavy, making them hard to maneuver. Reflect on your project needs before choosing.

Tips: Always check for user reviews. Feedback from other users can provide insights into performance. Test the equipment if possible. Familiarity can prevent operational mistakes. Additionally, ensure safety features are in place. Proper training for operators is essential for effective compaction.