+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the world of high-performance engines, the importance of "Con Rod Bearing" maintenance cannot be overstated. Renowned expert John Smith, a leading authority on engine components, emphasizes, “Proper care of Con Rod Bearings ensures longevity and performance.” These small pieces are crucial for engine efficiency and reliability.

Neglecting them can lead to disastrous consequences. For example, inadequate lubrication may cause wear and tear, resulting in engine failure. Regular inspections of Con Rod Bearings can prevent such issues. Carefully monitoring performance keeps these components in prime condition.

Yet, many overlook their significance. A lack of attention often leads to costly rebuilds and repairs. It's vital to strike a balance between performance enhancement and routine maintenance. A focused approach to Con Rod Bearings can yield impressive benefits for longevity and overall engine health.

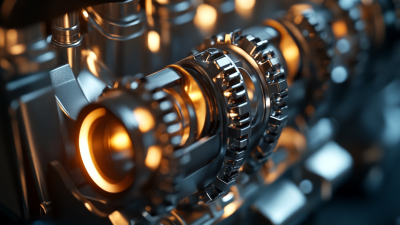

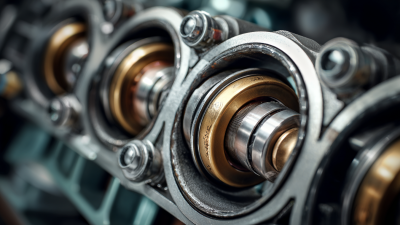

Con rod bearings play a crucial role in engine performance. They connect the piston rods to the crankshaft. This connection allows for smooth movement within the engine. When the engine operates, con rod bearings endure significant stress and friction. Their quality can greatly influence engine efficiency.

Proper maintenance is essential for these components. Regularly check the oil levels and quality. Good lubrication reduces wear and tear on the bearings. Using high-quality oil can make a difference too.

Tips: Always inspect con rod bearings during routine maintenance. Replace them if they show signs of wear. Monitor engine vibrations closely; unusual noises may indicate issues. Pay attention to oil pressure—it can signal bearing health. Keeping an eye on these can save you from costly repairs later.

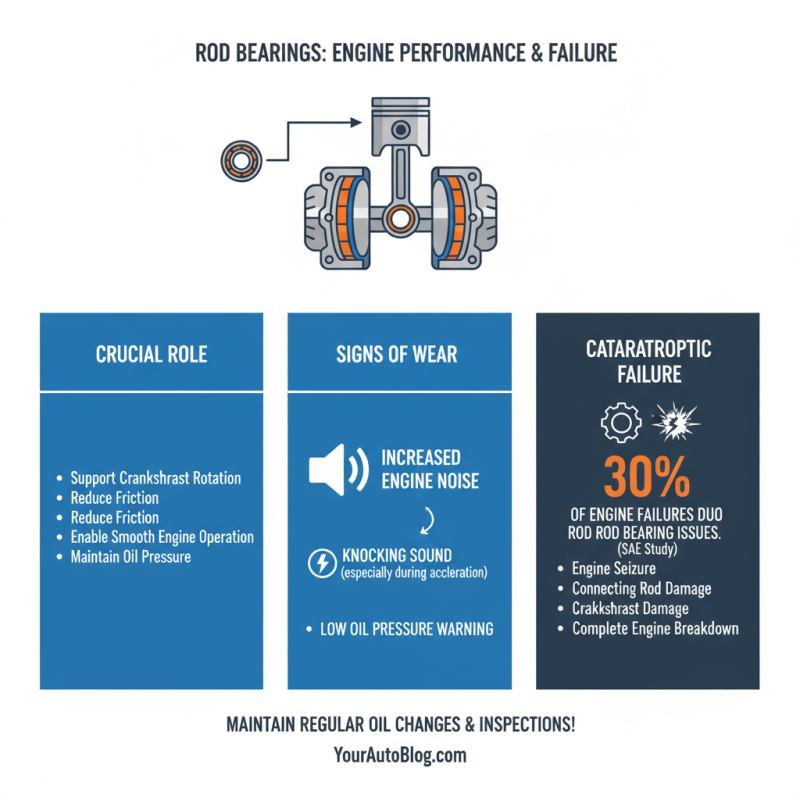

Con rod bearings play a vital role in engine performance, especially in high-performance applications. Common issues arise due to improper lubrication and misalignment. Consistent wear and tear can lead to severe engine damage. According to recent industry reports, nearly 30% of performance engine failures are linked to con rod bearing failures. This highlights the importance of regular maintenance.

It’s essential to monitor the oil viscosity closely. Using the right oil can prevent overheating and reduce friction. A tip for enthusiasts: always check for signs of metal debris in the oil. This could indicate a problem with the bearings.

Pay attention to rod bolt torque. Incorrect torque settings can lead to bearing distortion. An overlooked detail can have dire consequences. Experts recommend using a torque wrench for precise adjustments. Keep in mind that even slight misalignments can lead to catastrophic failures. Regularly inspecting alignment can save you trouble later.

| Best Practices | Common Issues | Impact on Performance | Maintenance Tips |

|---|---|---|---|

| Regular Inspections | Wear and Tear | Reduced engine efficiency | Inspect every 5000 miles |

| Proper Lubrication | Overheating | Increased friction | Use high-quality oil |

| Correct Installation | Misalignment | Potential engine failure | Follow manufacturer guidelines |

| Use Quality Bearings | Fatigue Cracking | Loss of power | Invest in reputable brands |

| Monitor Engine Performance | Oil Contamination | Engine knocking | Regular diagnostics |

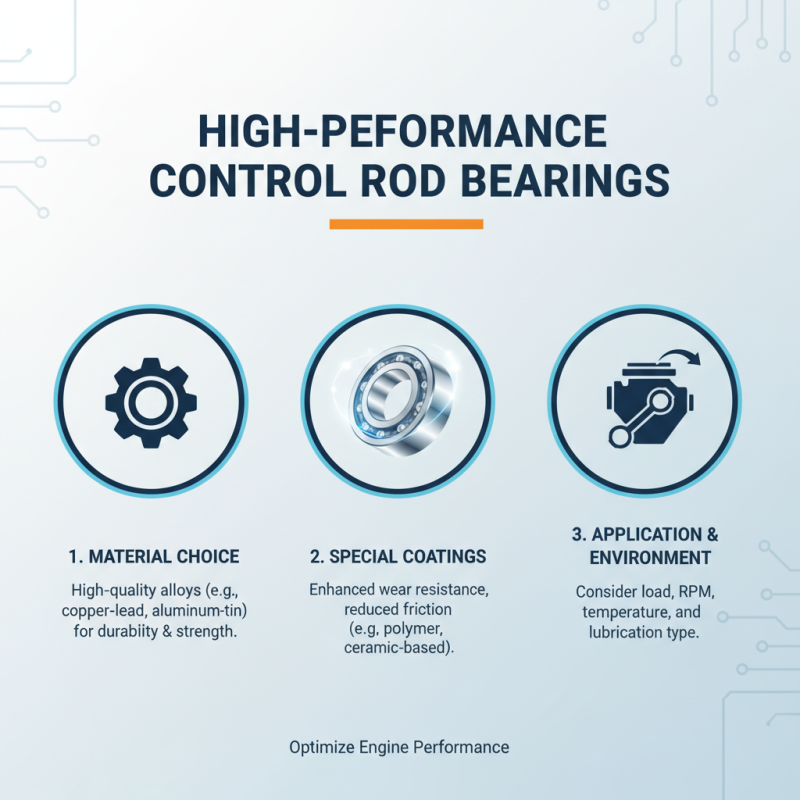

When selecting high-performance con rod bearings, several factors come into play. Material choice is crucial. Engine builders often prefer high-quality alloys for durability. Special coatings can enhance resistance to wear and improve performance. Always consider the specific application and environment.

Engine tolerances are vital too. They affect how bearings fit within the engine. Too tight, and they may seize. Too loose, and they might wear out quickly. It's essential to measure clearances accurately. Using proper tools ensures the right fit for high RPM applications.

Pay attention to oiling methods as well. Some designs promote better lubrication. A poorly lubricated bearing can lead to catastrophic engine failure. Monitor oil pressure and quality regularly. Small lapses in maintenance can lead to larger issues later on. Always stay vigilant and reflective in your maintenance practices.

Con rod bearings play a crucial role in the performance of an engine. They help ensure smooth operation by providing support for the connecting rod. Unfortunately, they are subjected to extreme heat and pressure, which can lead to premature wear. According to industry studies, up to 30% of engine failures are directly related to bearing issues. Regular maintenance is vital for prolonging their lifespan.

Tips: Always use high-quality engine oil. Poor lubrication can accelerate wear. Check oil levels and quality frequently. Aim for a filtration change every 5,000 miles for optimal performance.

Another key point is to monitor engine temperature. Overheating can compromise bearing integrity. Regularly inspect your cooling system. Replace any worn hoses or faulty thermostats. If you notice unusual noises or vibrations, don't ignore them. Addressing small issues early can prevent expensive repairs later.

Tips: Follow a strict maintenance schedule. Routine checks can help catch problems before they escalate. Keep detailed records of all services performed. This practice not only alerts you to patterns but can also improve resale value.

Con rod bearings play a crucial role in engine performance. However, wear and failure can lead to catastrophic engine damage. One common sign of wear is an increase in engine noise. A knocking sound, especially during acceleration, often indicates that the bearings are deteriorating. According to a study by the Society of Automotive Engineers, nearly 30% of engine failures are due to con rod bearing issues.

Another tell-tale sign is oil contamination. If you notice metal shavings in your engine oil, it’s a cause for concern. This could indicate excessive wear and tear on the bearings. Additionally, a decrease in oil pressure can signify that the con rod bearings are failing. Keeping an eye on these indicators is vital for vehicle longevity.

**Tips:** Regular oil changes can help prevent buildup. Use high-quality oil to lubricate the bearings effectively. Always check for unusual noises or oil leaks. Don’t ignore them; they could lead to expensive repairs down the road. Additionally, maintaining proper torque settings during installation can significantly impact the lifespan of the bearings.