+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

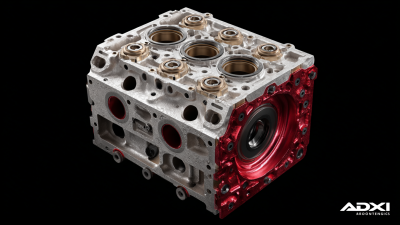

In the ever-evolving automotive landscape, the significance of

selecting the right Engine Cylinder Block

cannot be overstated. As engine performance and durability become increasingly crucial for manufacturers and consumers alike,

industry reports have shown a notable shift in focus toward optimizing engine components. According to a recent study by the

Society of Automotive Engineers, approximately

30%

of engine failures can be attributed to inadequate cylinder block configurations, underscoring the need for precision in selection.

Moreover, advancements in materials and manufacturing techniques have driven innovations in cylinder block design, leading to improvements

in thermal efficiency and weight reduction. As the demand for high-performance and eco-friendly engines continues to rise,

understanding

best practices for choosing the right Engine Cylinder Block

is essential for both enhancing vehicle performance and ensuring

long-term reliability.

In the ever-evolving automotive landscape, the significance of

selecting the right Engine Cylinder Block

cannot be overstated. As engine performance and durability become increasingly crucial for manufacturers and consumers alike,

industry reports have shown a notable shift in focus toward optimizing engine components. According to a recent study by the

Society of Automotive Engineers, approximately

30%

of engine failures can be attributed to inadequate cylinder block configurations, underscoring the need for precision in selection.

Moreover, advancements in materials and manufacturing techniques have driven innovations in cylinder block design, leading to improvements

in thermal efficiency and weight reduction. As the demand for high-performance and eco-friendly engines continues to rise,

understanding

best practices for choosing the right Engine Cylinder Block

is essential for both enhancing vehicle performance and ensuring

long-term reliability.

When selecting the right engine cylinder block, one of the most critical decisions revolves around the material choice—primarily, cast iron or aluminum. Cast iron is known for its durability and excellent wear resistance, making it a popular choice for high-performance engines. However, it tends to be heavier, which can affect the overall weight distribution and efficiency of the vehicle.

On the other hand, aluminum cylinder blocks provide significant weight savings, which can lead to improved performance and fuel efficiency. They often offer better thermal conductivity, allowing for faster engine cooling. However, aluminum can be less resilient under extreme conditions, potentially compromising durability in highly stressed applications.

**Tip:** Consider the intended use of your vehicle when deciding on the material; if it’s for racing or high-performance applications, you might lean towards aluminum for its lighter weight, while for long-lasting everyday use, cast iron might be the better option.

**Tip:** Always evaluate additional factors such as cost and maintenance, as aluminum blocks may require more careful handling and specific maintenance practices due to their softer nature compared to cast iron. Making an informed decision will ensure you achieve the right balance between performance and longevity.

This chart compares key performance metrics between Cast Iron and Aluminum engine cylinder blocks. The metrics evaluated include Durability, Weight, Cost, Thermal Conductivity, and Machinability. Each material has distinct advantages depending on the application and performance requirements.

The design of an engine cylinder block plays a crucial role in determining the overall performance and durability of an engine. The shape of the cylinder block impacts the engine's airflow dynamics, heat dissipation, and structural integrity. A well-engineered cylinder block allows for optimal combustion efficiency, which leads to better power output and fuel economy.

For instance, blocks with more rounded shapes can facilitate smoother airflow, while those with angular designs can enhance the rigidity needed for high-performance applications.

Moreover, materials used in cylinder block manufacturing also correlate with its design. Advanced alloys and composites are often employed to ensure lightweight yet strong structures. This balance between weight and strength can significantly affect an engine's responsiveness and longevity.

As manufacturers experiment with various configurations and materials, understanding how these design choices influence engine behavior is essential for anyone looking to boost their vehicle's performance and lifespan.

The right selection can lead to not only an increase in horsepower but also a reduction in wear and tear over time, making your engine more resilient and efficient.

When choosing the right engine cylinder block, weight considerations are paramount for achieving an optimal balance between durability and speed. A lighter cylinder block can enhance acceleration and fuel efficiency, contributing to improved overall performance. However, the materials used in the construction of these blocks must also provide the necessary strength to withstand the high stresses encountered during engine operation. Innovations in lightweight materials and manufacturing techniques have made it possible to create engine components that reduce weight without compromising reliability.

In the realm of performance and speed, the choice of a lightweight engine cylinder block can significantly influence the dynamics of a vehicle. Just as in the world of athletic training, where runners incorporate strength training to optimize their performance, engineers and automotive designers must focus on integrating lightweight yet robust materials to maximize engine efficiency. This careful consideration ensures that the engine can perform at its best while promoting longevity under challenging conditions, echoing the principles of balance that underpin effective training regimens and equipment selection in sports.

When selecting an engine cylinder block, cooling efficiency is one of the paramount factors to consider. The ability of the block to dissipate heat effectively can significantly influence the overall performance and longevity of the engine. A well-designed cooling system will help maintain optimal operating temperatures, preventing overheating and potential engine failure.

Tip: Look for cylinder blocks with features such as integrated coolant passages that improve heat transfer. Additionally, consider blocks made from materials with high thermal conductivity, such as aluminum, which can enhance cooling efficiency.

Another crucial aspect is the placement and size of the coolant channels. Ensuring that these channels are optimally designed will facilitate a more uniform cooling process throughout the engine.

Tip: When evaluating options, check for innovative designs that enhance coolant flow. Design elements like larger coolant passages or strategically placed baffles can lead to better cooling performance, thus improving engine reliability under stress.

| Best Practice | Description | Impact on Performance | Cooling Efficiency |

|---|---|---|---|

| Material Selection | Choose lightweight yet durable materials like aluminum or cast iron. | Improves power-to-weight ratio. | Enhances heat dissipation properties. |

| Design Precision | Ensure all dimensions and tolerances are finely detailed. | Boosts overall efficiency and fit with other engine components. | Supports uniform temperature distribution. |

| Surface Treatment | Apply coatings to enhance protection against wear and corrosion. | Extends engine life and reliability. | Improves fluid dynamics in cooling passages. |

| Cooling Channel Design | Optimize placement and shape of cooling channels within the block. | Enhances thermal management under load. | Maximized cooling efficiency reduces overheating risks. |

| Integration of Technologies | Incorporate advanced technologies like variable cooling systems. | Increases performance adaptability. | Ensures optimal cooling based on operating conditions. |

| Weight Distribution | Balance the design for optimal weight distribution. | Enhances handling and performance characteristics. | Affects overall thermal management during operations. |

| Testing and Validation | Conduct thorough testing to validate performance metrics. | Ensures reliability and efficiency before mass production. | Prevents overheating issues through validated designs. |

When selecting the right engine cylinder block, assessing compatibility with your existing engine components is crucial. A well-fitted cylinder block can lead to enhanced performance and longevity. According to a recent study by the Engine Builders Association, mismatched components can decrease engine efficiency by up to 15%. Hence, ensuring that your cylinder block aligns with the specifications of your engine's pistons, crankshaft, and heads can lead to a seamless integration and optimized performance.

**Tip:** Always refer to the manufacturer’s recommendations when selecting a cylinder block. Specific tolerances and clearances must be adhered to for effective performance. Don't overlook aspects like the material composition—aluminum blocks are known for being lighter while cast iron provides durability, each affecting performance under different operating conditions.

Moreover, it’s vital to take into account the cooling requirements of your engine. The cooling system must be compatible with the cylinder block to prevent overheating. According to the Society of Automotive Engineers, a poorly matched cooling system can lead to a 20% increase in component wear.

**Tip:** Invest in a detailed compatibility chart for your engine components. This prevents costly mistakes in your build and ensures you select the ideal cylinder block to enhance both performance and durability.