+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

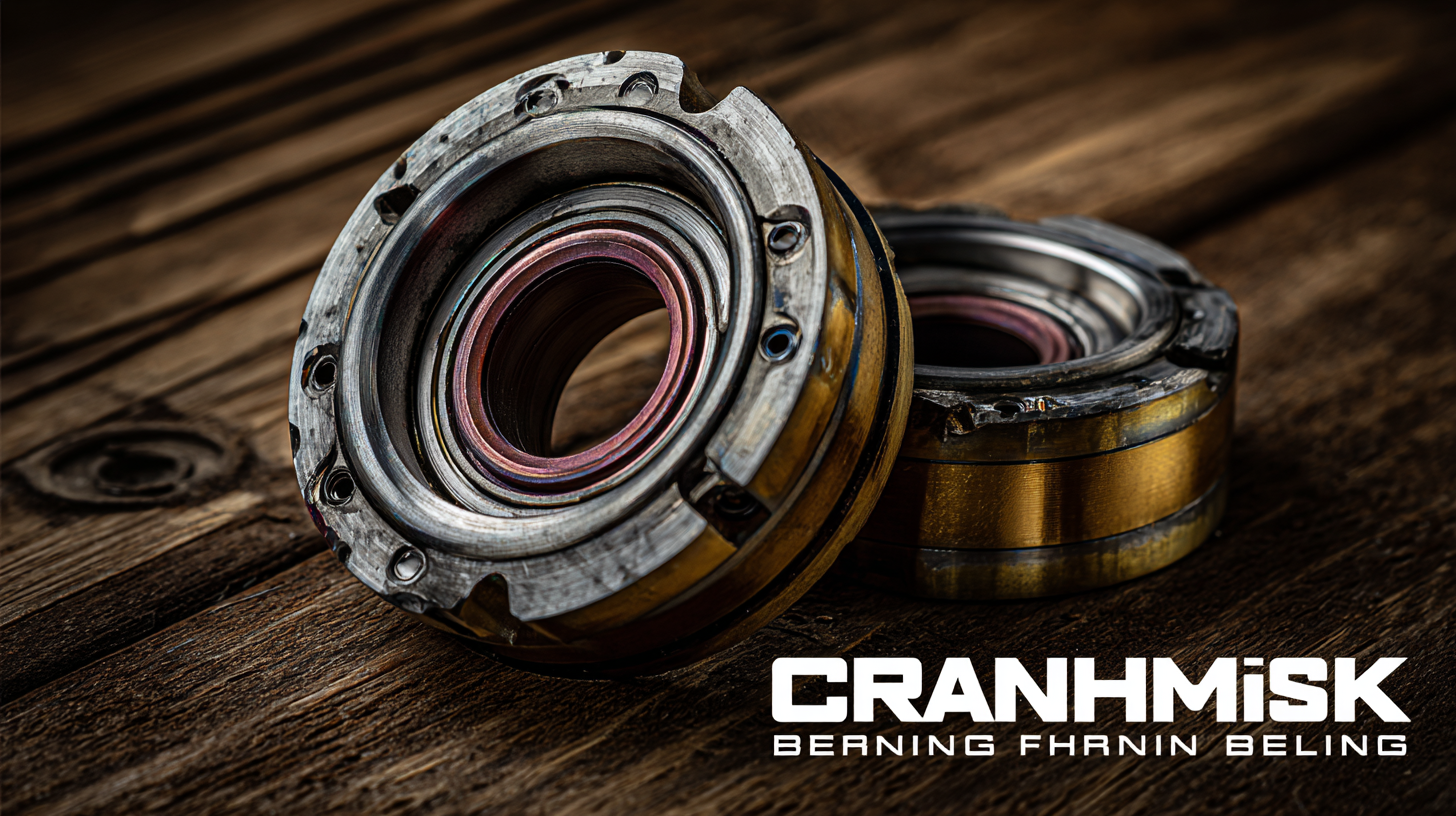

The performance and longevity of automotive engines heavily rely on the precision and quality of their components, with crankshaft bearings playing a pivotal role. A recent industry report from Murray State University highlights that approximately 30% of engine failures can be attributed to bearing-related issues, underscoring the importance of selecting the right crankshaft bearing for optimal engine performance. As global demand for high-quality engine components continues to rise, leading manufacturing facilities are focusing on advanced materials and stringent quality control measures. Moreover, data from the International Organization for Standardization suggests that over 75% of automotive manufacturers are now prioritizing enhanced bearing technologies to improve efficiency and reduce wear. In this blog, we will delve into the best crankshaft bearing technical specifications and provide a comprehensive installation guide to help you navigate this critical aspect of engine assembly.

Crankshaft bearings play a crucial role in the overall performance of an engine. Understanding the different types of crankshaft bearings, such as tri-metal, bi-metal, and composite bearings, can help you make better choices for your build. The type of bearing you select will depend on various factors, including engine design, application, and desired performance levels. Tri-metal bearings, for example, provide excellent strength and wear resistance, making them suitable for high-performance engines, while bi-metal options offer a good balance between performance and cost for daily drivers.

The materials used in crankshaft bearings also significantly impact engine performance. Common materials include copper-lead alloys and aluminum, each possessing unique properties that influence friction, durability, and heat dissipation. Choosing the right material can enhance oil flow and reduce the chances of bearing failure, which is critical during high-stress situations.

**Tip:** Always ensure proper clearances when installing crankshaft bearings. Incorrect clearance can lead to premature wear or catastrophic engine failure.

**Tip:** Regularly check and replace lubricant to maintain optimal performance and extend the life of your crankshaft bearings. Fresh oil reduces friction and keeps the bearings operating smoothly.

| Bearing Type | Material | Clearance (mm) | Load Capacity (N) | Impact on Performance |

|---|---|---|---|---|

| Standard | Copper-lead alloy | 0.025 - 0.050 | 8000 | Good durability, standard performance |

| High Performance | Babbit metal | 0.015 - 0.025 | 12000 | Enhanced performance and weight reduction |

| Racing | Aluminium-silicon alloy | 0.020 - 0.030 | 15000 | Maximized strength and reduced friction |

| Heavy Duty | Nickel-aluminium bronze | 0.030 - 0.045 | 10000 | Superior resistance to wear and corrosion |

When it comes to optimizing crankshaft bearing selection, understanding key technical specifications is essential. The primary factors to consider include bearing size, load capacity, and material composition. The bearing size must match the crankshaft design to ensure a snug fit, which directly influences engine efficiency. Load capacity refers to the maximum weight the bearing can handle while maintaining performance. Selecting bearings with the right load capacity is crucial for preventing premature wear and ensuring long-term reliability.

When it comes to optimizing crankshaft bearing selection, understanding key technical specifications is essential. The primary factors to consider include bearing size, load capacity, and material composition. The bearing size must match the crankshaft design to ensure a snug fit, which directly influences engine efficiency. Load capacity refers to the maximum weight the bearing can handle while maintaining performance. Selecting bearings with the right load capacity is crucial for preventing premature wear and ensuring long-term reliability.

Material composition is another critical specification that affects a bearing's performance. Common materials such as aluminum, bronze, or polymer each offer unique benefits depending on the application. For high-performance engines, bearings made from advanced composites can reduce friction and enhance durability. Additionally, understanding the lubrication requirements of different materials can help in preventing overheating and maintaining optimal performance. By focusing on these technical specifications, mechanics and enthusiasts alike can make informed choices that enhance engine longevity and performance.

When it comes to installing crankshaft bearings, precision is paramount. The successful performance of an engine largely hinges on how well these components fit together. Begin by meticulously cleaning the crankshaft and bearings, as any debris can lead to improper alignment and premature wear. Use a feeler gauge to check tolerance and ensure that the bearings are seated correctly in the housing. This step is crucial, as even a slight misalignment can result in significant mechanical issues down the line.

Next, attention to torque specifications during installation cannot be overstated. Utilizing a calibrated torque wrench ensures that the crankshaft bolts are tightened to the manufacturer's recommended settings, which is essential for maintaining the integrity of the bearings. Incorporating a lubricant on the bearing surfaces before installation will also help alleviate initial wear and support smoother operation right from the start. Adopting these best practices will not only enhance the lifespan of the crankshaft bearings but will also contribute to the overall efficiency and performance of the engine, ultimately unlocking its true potential.

When it comes to crankshaft bearing installation, avoiding common pitfalls can make a significant difference in engine performance and longevity. One frequent mistake is neglecting to properly clean the bearing journal and block before installation. Any debris or grime can lead to poor lubrication and premature wear. Always ensure that the surfaces are spotless and free from old oil residues to create a smooth contact surface.

Another tip is to avoid over-tightening the bearing caps. Many mechanics believe that the tighter, the better; however, excessive torque can lead to deformation of the bearing, causing catastrophic failures. It’s essential to adhere to the manufacturer's specified torque settings. Additionally, be cautious of installing bearings dry; always apply the proper assembly lubricant before installation to ensure optimal initial lubrication.

Lastly, double-check the orientation of the bearings and caps, as incorrect alignment can quickly lead to engine failure. Mistaking back for front could disrupt the oil flow, leading to overheating. A little attention to detail during the installation phase can save you a lot of trouble down the road.

In the quest for maximizing engine performance, the role of crankshaft bearings cannot be overstated. Proper installation and meticulous attention to technical specifications yield significant performance gains, as illustrated by data-driven outcomes. By adhering to the recommended specifications, such as clearances and lubrication requirements, mechanics can ensure optimal oil flow and reduced friction. This significant reduction in resistance translates into enhanced horsepower and acceleration, demonstrating the importance of precision in installation.

Measuring performance gains goes beyond mere horsepower figures; it also encompasses longevity and reliability of the engine. Data collected from engines equipped with correctly installed bearings reveals a marked improvement in overall efficiency. Tests indicate lower operating temperatures and reduced wear on critical components, leading to less frequent maintenance and repair costs. These findings emphasize the necessity of prioritizing technical accuracy and proper installation techniques in the pursuit of unlocking an engine's full potential.