+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the evolving landscape of industrial automation, the choice of arm cylinders is crucial. Experts, such as Dr. Emily Rhodes, highlight this importance. She states, "The right arm cylinder can significantly improve efficiency in robotic applications." Her insight reflects a growing focus on technological advancements.

As businesses aim for higher productivity, selecting the best arm cylinder becomes a pivotal task. In 2026, a variety of options will be available, each with unique features. It's important to analyze these features closely. Some options may promise high performance but fall short in reliability.

Choosing the right arm cylinder is not just about specifications; it's also about long-term impact. Potential users must weigh their choices carefully. Many new designs may surface, but does innovation always mean better quality? Understanding this nuance can lead to better decisions.

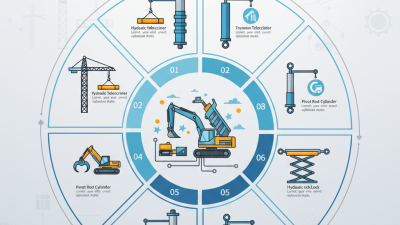

In 2026, the demand for arm cylinders is expected to grow significantly. Industries are focusing on automation and efficiency. The shift towards electric actuators is evident, with reports indicating a projected market growth of 15% annually. Energy efficiency is becoming a priority. Many companies are opting for lighter materials to enhance performance.

Not all arm cylinders will meet future needs. Hydraulic systems still dominate specific applications, but their limitations are clear. Maintenance costs for hydraulic systems are higher. Many users are seeking alternatives that are more cost-effective over time. Pneumatic cylinders are another option, known for their speed and precision. However, they may not deliver the consistent force required for some heavy-duty tasks.

As we move forward, companies must reflect on their choices. The complexity of each type can create challenges. Users often struggle to find the right balance between cost and performance. Making poor choices can lead to downtimes and increased expenses. It's crucial to evaluate the specific requirements of each application. Careful consideration will lead to better decisions in a rapidly evolving market.

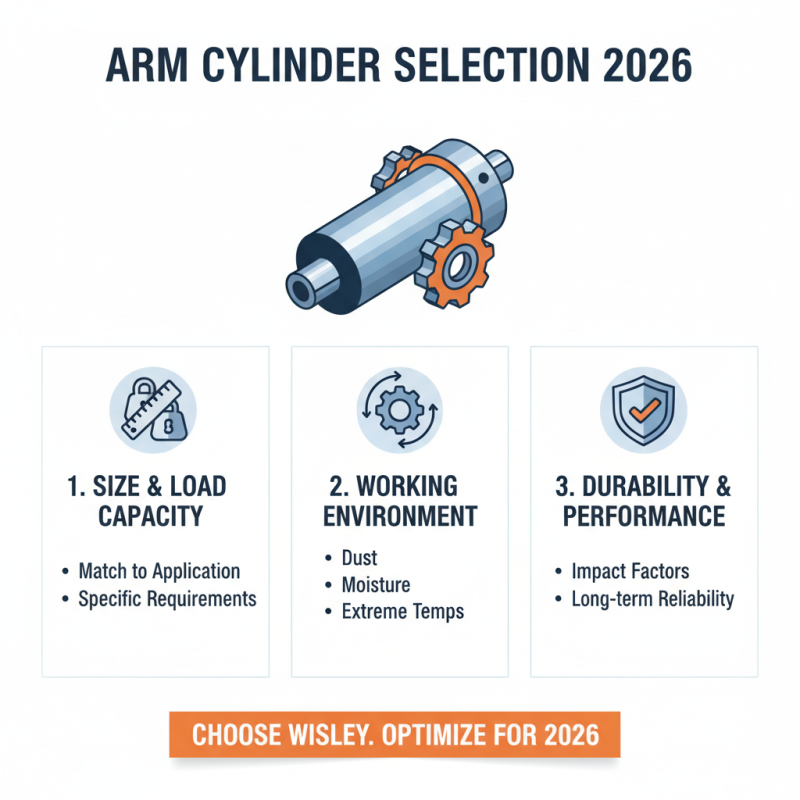

When selecting arm cylinders for 2026, several key factors come into play. The size and load capacity are crucial. You must match the cylinder to your specific application requirements. Consider the working environment as well. Will it endure dust, moisture, or extreme temperatures? These factors can significantly impact performance and durability.

Another area to reflect on is the type of material used in construction. Aluminum cylinders offer lightness, while steel ones provide strength. Each has its trade-offs. You might find that one excels in a particular situation but fails in another. It's essential to evaluate how these materials align with your operational needs.

Lastly, functionality plays an important role. Think about speed and efficiency. How quickly do you need the cylinder to respond? Different models and designs can vary significantly in responsiveness. Testing various options, even if it means potential errors, can lead to better decision-making. Emphasizing the right factors now can lead to improved performance and longevity down the road.

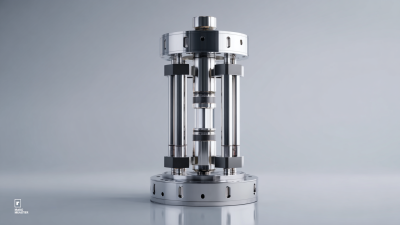

When considering arm cylinders for 2026, focus on key features that enhance performance. High-efficiency designs are essential. Look for cylinders with enhanced stroke lengths that maximize reach and functionality. Compact builds matter too, as they allow for versatile applications across various industries.

Durability should never be overlooked. Materials that can withstand harsh environments extend the lifespan of arm cylinders. Pay attention to seal technology. High-quality seals prevent leaks and maintain consistent pressure. This ensures reliable operation even under demanding conditions.

Customization options can also add value. Some users might need specific dimensions or attachments. Those variations can lead to improved workflows. However, remember that complexity can sometimes introduce risks. More features may mean more potential failure points. Always weigh the benefits against the drawbacks, as the best choice is not universally defined.

As we approach 2026, selecting the best arm cylinders for various applications becomes crucial. Different types of arm cylinders vary in design and functionality. Some possess lightweight materials, enhancing ease of use. Others may offer higher performance but at a steeper cost. It’s essential to consider the specific requirements for each project before making a choice.

When comparing leading brands, factors like durability and efficiency must come into play. Some cylinders are designed for heavy-duty applications and withstand extreme conditions. However, they may be overly robust for lighter tasks, making them less cost-effective. On the other hand, lighter cylinders can be fragile, posing risks in demanding environments. Users should evaluate their actual needs, sometimes finding that options available are not perfectly aligned with project demands.

While variety exists, one size rarely fits all. Where does that leave teams trying to optimize their performance? The selection process can seem daunting. It’s essential not to rush and to reflect on what will truly serve your goals. Making a smart choice means balancing features, costs, and specific project needs. This balance often requires revisiting choices and re-evaluating prior assumptions.

| Feature | Specification A | Specification B | Specification C |

|---|---|---|---|

| Max Pressure (psi) | 2500 | 3000 | 3500 |

| Bore Size (inches) | 2.5 | 3.0 | 3.5 |

| Stroke Length (inches) | 20 | 24 | 30 |

| Weight (lbs) | 30 | 35 | 40 |

| Material | Aluminum | Steel | Composite |

| Operating Temperature (°F) | -20 to 180 | -20 to 200 | -10 to 210 |

As we look toward 2026, arm cylinder technology is evolving rapidly. Manufacturers are focusing on durability and energy efficiency. Lightweight materials are becoming increasingly popular. This shift allows for better performance in various applications. Engineers are exploring new designs that reduce friction. These innovations can enhance the lifespan of the cylinders.

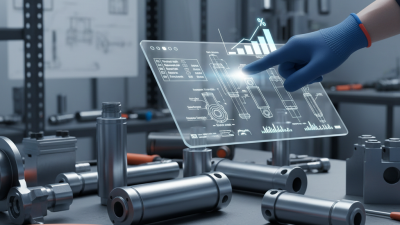

One of the emerging trends is smart technology integration. Sensors in arm cylinders can monitor performance in real-time. This capability provides valuable data for maintenance and operational efficiency. However, the challenges of affording such technology remain. Not every company can easily adapt to these changes. There’s a need for practical solutions that balance cost and innovation.

Another important consideration is sustainability. Manufacturers are beginning to adopt eco-friendly materials. This transition can lead to a reduced environmental footprint. It's not without its difficulties. Sourcing sustainable materials can be complex and expensive. There’s a lot to ponder as we advance. The future of arm cylinders is promising, but challenges persist.