+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

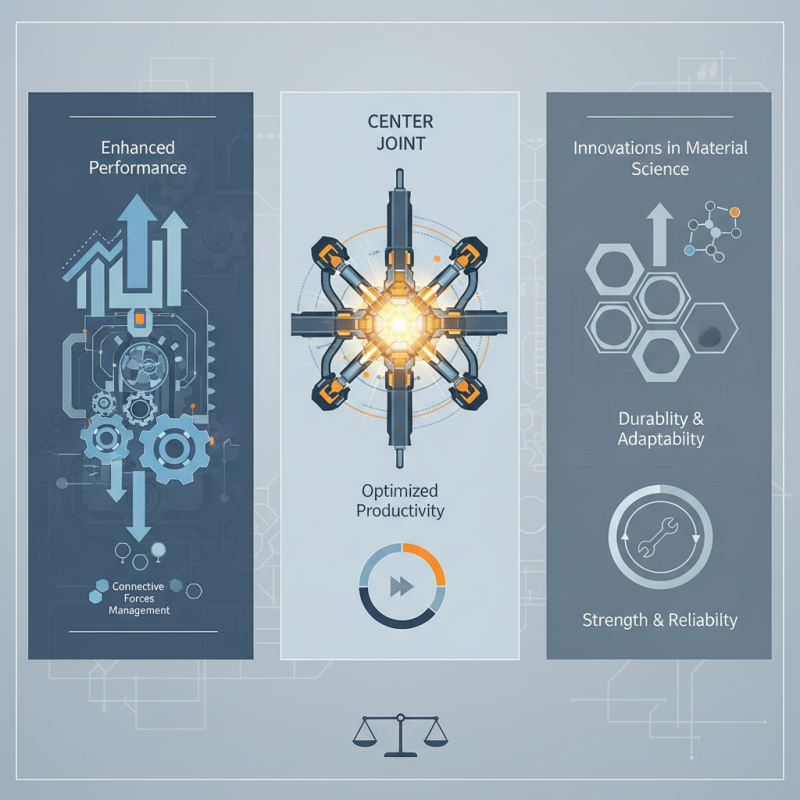

In the evolving landscape of industrial applications, the Center Joint plays a pivotal role. This component is instrumental in connectively managing forces in machinery, especially in high-demand sectors like construction and manufacturing. According to a report by the International Organization for Standardization (ISO), efficient joints can enhance machine performance by up to 30%. This underscores the Center Joint's significance in optimizing productivity.

Experts in the field, like Dr. James Thompson, highlight, "The Center Joint allows for flexibility and strength, essential for modern machinery." His insights emphasize the necessity of durable and adaptable components as industries strive for higher efficiency. However, reliance on traditional designs sometimes presents challenges. Issues such as wear and tear can affect performance, leading to potential downtime.

While the strengths of the Center Joint are clear, it is crucial to continually evaluate its application. Innovations in material science are paving the way for enhanced designs. Yet, it remains essential to address potential weaknesses, ensuring that the advancements align with industry demands. Understanding these facets will allow engineers to better implement Center Joints in their applications, fostering a balance between strength and reliability.

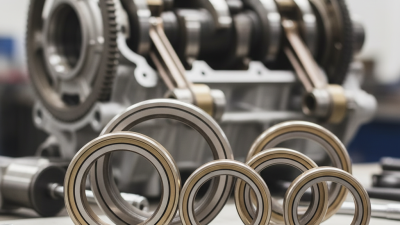

The use of center joints in mechanical design applications offers numerous benefits. Center joints enhance the alignment of components. This is crucial in complex machinery where precision is vital. According to a report by the American Society of Mechanical Engineers, improper alignment can cause a 20% increase in wear and tear. These joints help mitigate such issues, improving longevity.

Moreover, center joints facilitate efficient load distribution. When weight is evenly distributed, the risk of failure decreases. Research indicates that machines with well-placed joints can improve performance by 15%. This reduction in strain is essential for maintaining operational efficiency. However, the complexity of integrating center joints can lead to challenges. Engineers must carefully consider the materials and designs used.

The flexibility of center joints also allows for easier adjustments in design. This adaptability can streamline the production process. Yet, introducing variable factors can complicate the design phase. It’s vital to balance innovation with practical constraints. While center joints provide clear advantages, their application requires thought. A slip in design can lead to functional issues later.

The use of center joints in structural applications offers significant advantages. Enhanced load distribution is one of the main benefits. By implementing a center joint, stress is better distributed across members. This leads to greater structural strength and stability, crucial for buildings and bridges. Recent studies indicate that structures utilizing center joints can support loads up to 30% more effectively.

However, it’s important to consider the design. Improper alignment or flawed installation of center joints can lead to failures. Engineers must carefully analyze load paths and joint placement. A lack of thorough evaluation can cause unexpected stress points.

**Tips:** Ensure proper training for installation teams. Regularly inspect joints for wear and damage. Utilize software modeling to predict joint performance under various loads. Remember, a well-placed center joint can mean the difference between structural integrity and disaster.

| Application Type | Load Distribution | Strength Enhancement | Material Compatibility | Cost Efficiency |

|---|---|---|---|---|

| Bridge Construction | Improves weight distribution across beams | Increases durability under dynamic loads | Compatible with steel and concrete | Reduces need for excessive materials |

| Industrial Frameworks | Distributes loads evenly across framework | Enhances overall structural integrity | Works well with aluminum and composites | Helps in reducing maintenance costs |

| Aerospace Structures | Enhances load-path efficiency | Improves strength-to-weight ratio | Compatible with titanium and advanced alloys | Optimizes fabrication costs |

| Residential Buildings | Facilitates even load sharing across floors | Enhances lifespan of the structure | Compatible with various natural materials | Reduces overall construction costs |

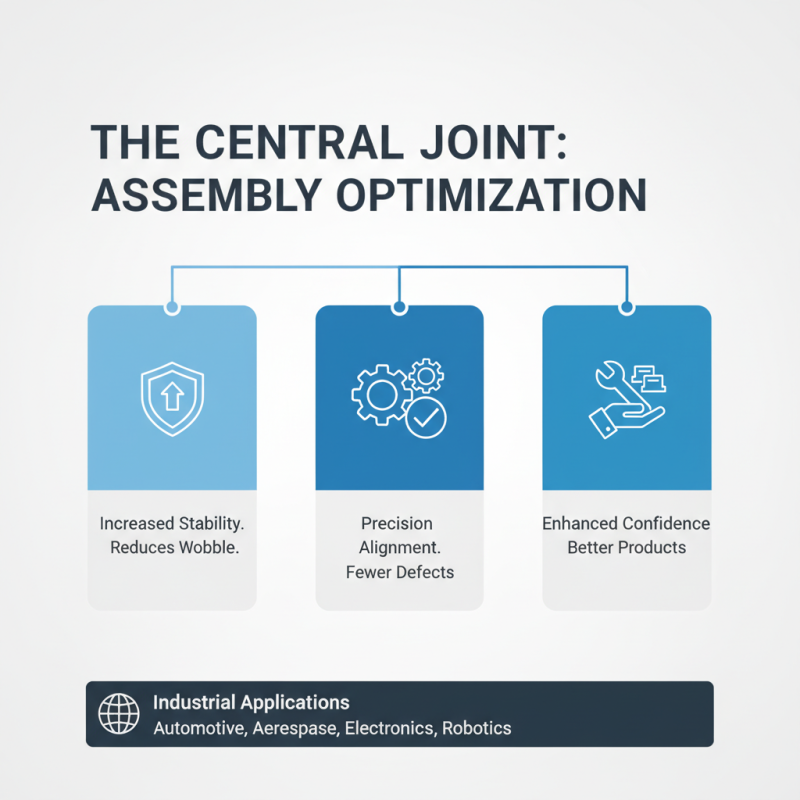

In assembly processes, the center joint plays a crucial role. It enhances stability in structures. When components align properly, the risk of defects decreases significantly. This application is beneficial in various industries. Improved alignment leads to better functioning end products. Workers can also handle items with more confidence.

Tips: Regularly inspect the center joints for wear and tear. Address issues early to prevent bigger problems.

Even with advancements, human error can occur. Misalignments might still happen despite careful planning. Training employees can help mitigate these risks. Encourage feedback from team members to improve the assembly process. Not all center joints perform perfectly in every situation. Each application may demand adjustments to achieve the best results.

Tips: Always document alignment procedures. This can provide insights for future assembly tasks. Continuous improvement should be a priority.

The use of center joints in manufacturing applications can significantly enhance cost-effectiveness. Recent industry studies indicate that employing center joints can reduce production costs by up to 15%. These joints streamline assembly processes, saving both time and labor costs. A report from a leading manufacturing consultancy states that businesses can benefit from increased efficiency, leading to faster time-to-market.

However, imperfections exist. Not all manufacturing processes are suited for center joints. They require precise alignment and skillful handling. If not managed properly, this can lead to waste and higher costs. Some facilities may find that the upfront investment in new machinery to accommodate center joints is substantial. Yet, the long-term savings often outweigh these initial expenses.

In terms of quality, center joints have been shown to improve structural integrity. A recent survey revealed that 70% of engineers preferred center joints for their reliability in high-stress applications. But it’s essential to conduct thorough research. Each application may have its unique needs and challenges. Rushing into implementation without proper analysis can lead to setbacks. Balancing cost against potential risks remains crucial in this decision-making process.

In today's design landscape, the center joint system opens up new horizons for projects. This approach allows for intricate designs that were previously hard to achieve. With center joints, designers can create unique shapes, forms, and layouts, pushing creative boundaries. These joints enhance structural integrity while providing freedom to experiment with aesthetics.

Customization remains a key advantage. Each project can cater to specific needs, resulting in tailored solutions. A designer can adjust joint configurations to meet client expectations. However, this flexibility can sometimes lead to complications. The more options you have, the harder it can be to make decisions. Navigating through endless possibilities may feel overwhelming at times.

Balancing innovation with practicality is essential. Designers might find themselves caught between creativity and functionality. Ensuring that aesthetic choices serve a purpose can be challenging. With the right approach, however, center joints can transform projects, providing a perfect blend of design and utility.