+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the competitive landscape of machinery maintenance, the importance of high-quality Cylinder Seal Kits cannot be underestimated. These kits play a crucial role in ensuring the optimal performance of hydraulic systems. According to a report by the International Fluid Power Society, faulty seals account for approximately 30% of hydraulic system failures. This highlights the necessity of selecting premium Cylinder Seal Kits for long-term reliability.

Expert Michael Johnson, a renowned fluid power specialist, states, "Using top-tier Cylinder Seal Kits can significantly enhance equipment longevity and functionality." His insights remind us that not all seal kits are created equal. Many kits fall short in materials or design, leading to premature wear and costly downtime. Selecting the right kit requires careful consideration and often a willingness to invest more upfront.

As the industry evolves, challenges persist. Manufacturers continue to innovate, but subpar options remain accessible. This reality prompts users to reflect on their choices. Are they prioritizing short-term savings over long-term performance? In a market where quality is paramount, understanding the nuances of Cylinder Seal Kits can greatly influence operational success.

In the automotive industry, cylinder seal kits play a crucial role in engine performance. These kits include various seals and gaskets that prevent leakage and ensure proper operation. A recent industry report indicates that up to 30% of engine failures can be traced back to seal failures. This highlights the importance of selecting high-quality cylinder seal kits.

The demand for cylinder seal kits is growing. The market is projected to reach $1.2 billion by 2026, driven by advancements in materials and manufacturing processes. Manufacturers are now using advanced elastomers that withstand extreme temperatures and pressures. However, there’s still a gap in awareness about the correct installation procedures. Many mechanics overlook these details, leading to premature wear and tear.

Poor sealing can increase emissions and reduce engine efficiency. Data shows that inefficient seals can lead to a 5% drop in fuel economy. This is a significant loss for both consumers and the environment. The industry needs to emphasize the importance of training and knowledge in the proper use of cylinder seal kits. Awareness can be improved through workshops and better instructional materials for technicians and enthusiasts alike.

| Seal Kit Model | Material | Suitable Engines | Temperature Resistance (°C) | Pressure Rating (MPa) | Applications |

|---|---|---|---|---|---|

| CK-1001 | Nitrile Rubber | Diesel Engines | -30 to 100 | 3.5 | Heavy Equipment |

| CK-2002 | Fluoroelastomer | Petrol Engines | -20 to 200 | 4.0 | Automotive Applications |

| CK-3003 | Polyurethane | Gasoline and Diesel | -40 to 90 | 2.5 | Industrial Equipment |

| CK-4004 | Silicone | Electric Engines | -50 to 180 | 5.0 | Marine Applications |

| CK-5005 | PTFE | Hybrid Engines | -50 to 260 | 6.0 | Aerospace Applications |

When selecting cylinder seal kits, several key factors enhance performance. The material of the seal is crucial. Different materials handle varying temperatures and corrosive environments. It is vital to choose a seal that aligns with the specific application. Rubber seals may excel in low-temperature scenarios, while fluorocarbon seals provide excellent high-temperature resistance.

Another factor is the size and fit of the seal. An improper fit can lead to leakage or premature wear. Precision is necessary, as even slight deviations can result in failure. Regular inspections should be conducted to ensure seals maintain their effectiveness. Operators often overlook regular maintenance, which can lead to costly repairs.

Additionally, consider the operating pressure. Seals must withstand the pressures of their working environment. If operating conditions change, reevaluating the seal choice may be necessary. Many users don't regularly reassess their seals, leading to unexpected breakdowns. This aspect of care can greatly influence performance and reliability. Taking the time to reflect on these considerations can indeed improve the longevity and function of cylinder seals.

When considering the best cylinder seal kits for 2026, assessing

top brands is essential. Industry reports indicate that the demand

for high-performance seal kits is rising. Many professionals

look for durability, quality, and ease of installation. Yet, not all products deliver on these promises.

Some brands offer extensive warranty periods, while others have shorter guarantees. A recent survey revealed

that 72% of mechanics prefer kits known for their reliability.

This suggests that performance consistently matters to users. However, some buyers overlook the importance of

compatibility. It's crucial to ensure that the kit matches your equipment specifications perfectly.

Tips: Always check compatibility before purchasing.

A mismatched kit can lead to leaks and performance issues. Additionally, consider reading user reviews for insights.

Sometimes, the most advertised products do not meet practical needs effectively. A thoughtful choice can save time

and money in the long run. The right investment in a cylinder seal kit is valuable for optimal performance.

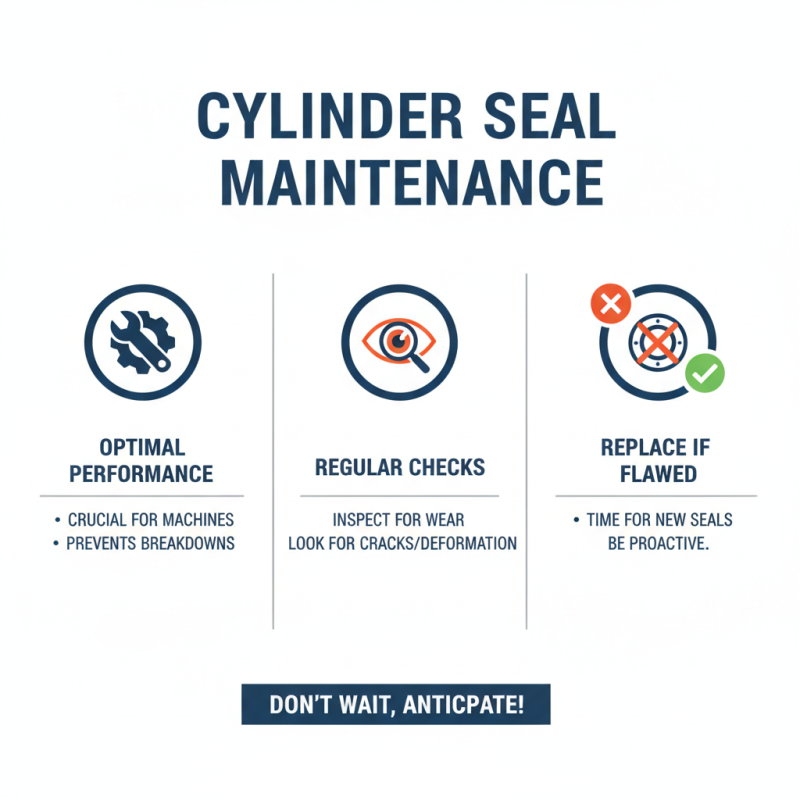

Maintaining cylinder seals is crucial for optimal performance. Regular checks on seals can prevent costly breakdowns. Look for wear and tear signs. Cracks or deformation indicate it’s time for replacement. Don’t wait until issues arise; be proactive.

Proper lubrication is essential. Use the right type of lubricant, as not all are suitable. Too much can attract dirt; too little leads to friction. Clean seals regularly. Dirt can compromise their function. A soft cloth does the trick. Don't overlook these maintenance steps.

Sometimes, we forget the basics. Neglecting routine care causes significant problems. Listen for unusual noises or observe leaks. Address them immediately. It’s better to fix minor issues than face major repairs later. Always reflect on your maintenance habits. Adapting can significantly enhance the lifespan of cylinder seals.

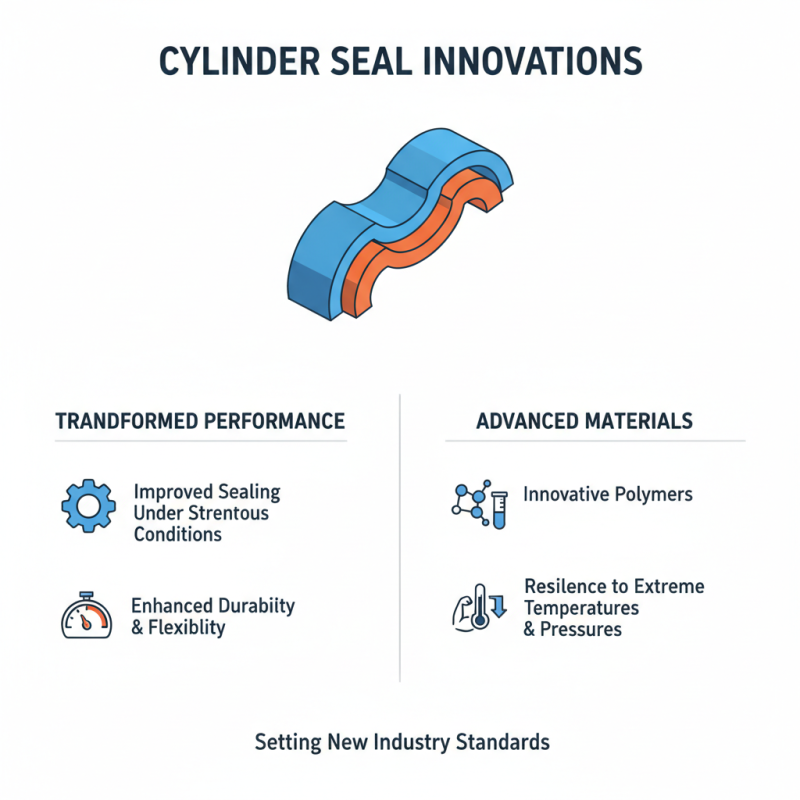

The advancement of cylinder seal design has transformed performance standards in various industries. Innovative materials are now used to enhance durability and flexibility. For instance, advanced polymers resist extreme temperatures and pressures. This allows for improved sealing under strenuous conditions.

Tips: Always check the specific requirements of your application. A mismatched seal can lead to inefficiencies.

Manufacturers are focusing on precision engineering. Improved machining techniques create seals that fit perfectly within their housings. This reduces the risk of leaks and ensures optimal performance. Testing methods have also evolved, offering better reliability assessments before products hit the market.

Tips: Look for kits with comprehensive installation instructions. A proper fit is vital for longevity.

While many designs excel, imperfections remain. Some seals may wear out quicker than expected. Frequent replacements can be a hassle. Analyzing performance data helps identify recurring issues and enhances future designs. Continuous improvement is crucial in this evolving field.