+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

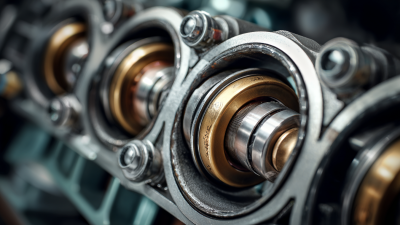

When it comes to enhancing engine performance, selecting the right con rod bearing is vital. These components play a crucial role in engine efficiency and longevity. A high-quality con rod bearing reduces friction and ensures a smooth operation. This directly translates to improved horsepower and torque.

Many options are available in the market, each claiming superiority. It can be overwhelming for car enthusiasts. How do you know what is truly effective? Consider weighing factors like material, size, and design. Investing in the right con rod bearing might seem costly, but the benefits can outweigh the initial expense.

Some may overlook the importance of proper installation and maintenance. Improper fitting can lead to disastrous outcomes, even with premium parts. Reflecting on your choices is essential for optimal performance. Every detail matters when fine-tuning your engine's capabilities.

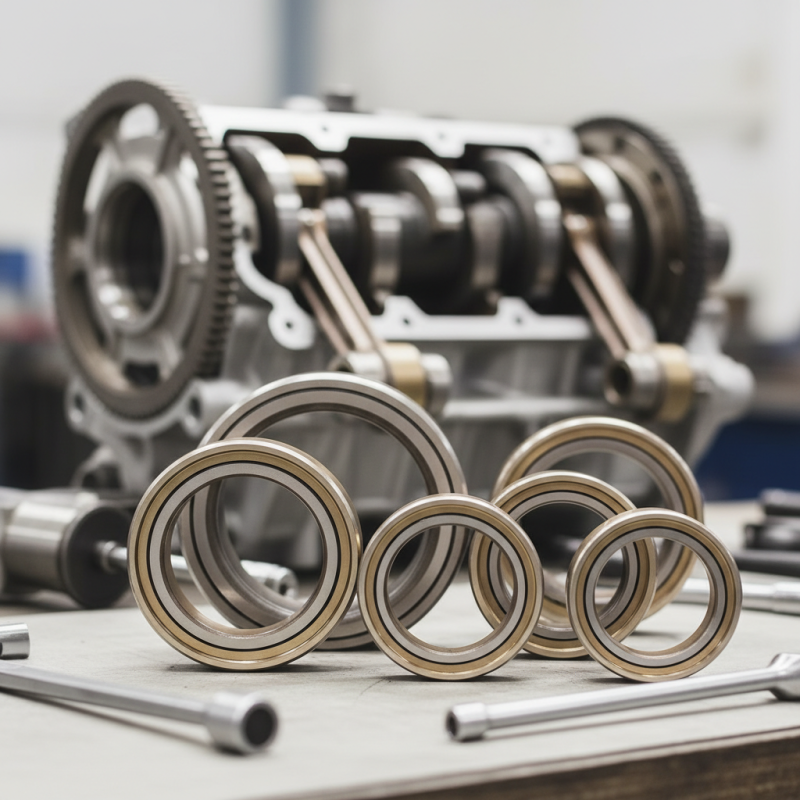

When selecting con rod bearings for engine performance, several factors come into play. Material choice significantly influences durability and performance. Typically, bearings are made from metals like aluminum or copper, each offering various benefits. Aluminum is lightweight, enhancing overall engine speed, while copper provides excellent thermal conductivity.

The thickness of the bearing is another key factor. Thicker bearings can better handle higher loads. However, they might create additional friction. Engine type also matters. High-performance engines may demand tighter tolerances. Sometimes, achieving the perfect fit can be tricky.

Proper lubrication is essential for optimal function. Insufficient lubrication can lead to severe wear and damage. It’s crucial to strike a balance between bearing clearance and oil flow. Regular monitoring often gets overlooked. Ignoring these details can result in significant performance declines over time. By considering these factors, you can make informed choices for enhancing your engine’s performance.

| Bearing Type | Material | Max RPM | Typical Application | Expected Lifespan |

|---|---|---|---|---|

| Steel Backed | Bi-metal | 8000 RPM | Performance Racing | 50,000 miles |

| Fully Cast | Aluminum | 7000 RPM | Street Performance | 40,000 miles |

| Plastigage | Polymer-Based | 6000 RPM | Daily Driving | 30,000 miles |

| Race Spec | Copper Lead | 9000 RPM | High-Performance Racing | 25,000 miles |

| High Load | Steel-Copper | 6500 RPM | Heavy-Duty Trucks | 60,000 miles |

Con rod bearings are essential for engine performance. They allow smooth rotation of the connecting rod. Understanding the types available helps in selecting the right option.

There are several types of con rod bearings. The most common are standard and performance bearings. Standard bearings are often made of soft metals. They provide basic functionality but may wear out faster. In contrast, performance bearings are engineered for durability. They can handle higher loads and temperatures.

Tips: Always check the compatibility of bearings with your engine. A mismatch can lead to severe damage. Regular inspection of your bearings is crucial. Signs of wear include unusual noises and vibrations.

Additionally, materials matter. Some bearings utilize composite materials for added strength. Others rely on traditional metal alloys. Each has its pros and cons. Weigh your choices carefully. Remember, investing in quality bearings pays off in reliability.

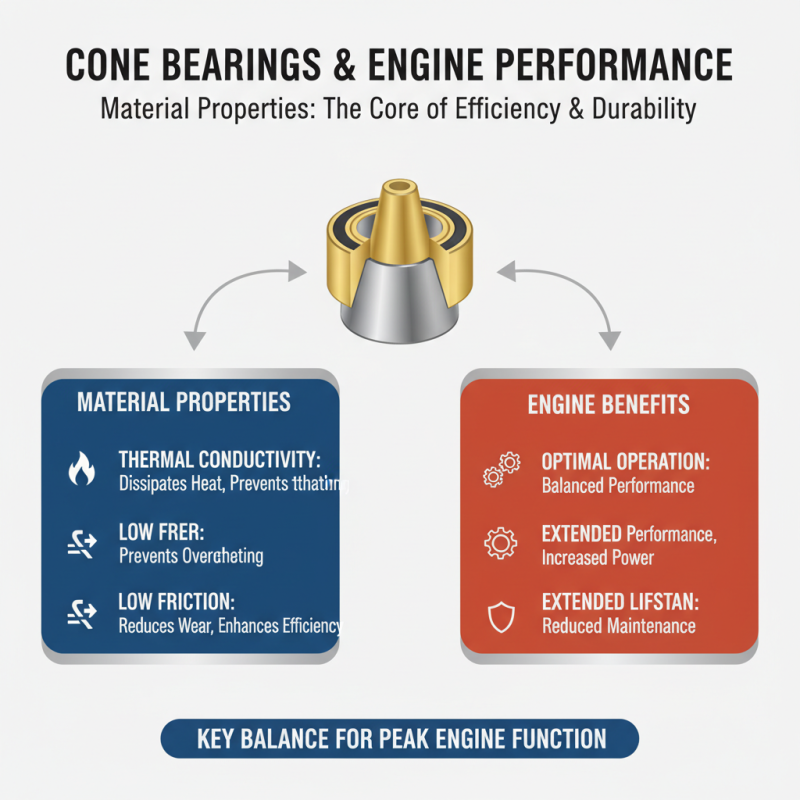

Con rod bearings play a crucial role in engine performance. Their material properties significantly affect various aspects of engine efficiency and durability. For example, some materials offer excellent thermal conductivity, while others excel in reducing friction. This balance is essential for optimal engine operation.

High-strength polymers and advanced alloys are becoming popular. They weigh less and provide better wear resistance compared to traditional materials. According to recent industry reports, switching to high-performance materials can enhance bearing lifespan by up to 30%. However, the choice of material is not always straightforward. Some options may compromise strength under high temperatures, leading to failure.

The effect of surface finish also cannot be ignored. A smoother surface reduces friction and improves oil retention. However, achieving this finish can be challenging. Inconsistent processes can lead to variations in performance. Some manufacturers report that 20% of their products fail quality tests due to surface issues. These factors underline the complexity of selecting the right con rod bearing materials for enhancing engine performance.

When enhancing engine performance, con rod bearings play a crucial role. These components support the connecting rods, allowing them to move smoothly. High-quality bearings reduce friction and heat, improving overall efficiency. Engine builders often seek better performance, aiming for both durability and power.

In 2026, some notable options exist in the market. Many choices cater to different engine types and performance levels. Lightweight materials are common, helping to improve acceleration. Some designs even focus on reduced resistance, offering a smoother operation. Performance enthusiasts want reliability, and there's a variety of models to explore. However, not every product will perform as expected. Some may not fit perfectly or may wear out faster than anticipated.

Choosing the right con rod bearing requires careful consideration. Engine specifications must align with the selected bearing. Compatibility is vital, as mismatched parts lead to serious issues. Testing and feedback are key to understanding which models truly enhance performance. Each option has its strengths and weaknesses. It is essential to reflect on experiences when making a choice.

When optimizing con rod bearing performance, installation plays a crucial role. Ensure the work area is clean. Dirt can impair the bearings, leading to engine failures. Use a torque wrench to achieve the correct tightening specifications. It’s easy to overlook this step, but it’s vital for longevity.

Check every con rod for signs of wear or damage before installation. A small imperfection can affect the entire engine’s function. Pay attention to the bearing clearance. Clearances that are too tight or too loose can lead to serious problems. Use a feeler gauge to make adjustments as necessary.

Don’t rush through the installation. Take your time to ensure everything is aligned properly. Misalignment can cause uneven wear. Double-check each step for consistency. Remember, even experienced builders can miss details. Regularly review the process to identify areas for improvement. This mindset will enhance your work quality and engine performance.